Carbon fiber broken filament amount testing device

A test device, a technology of carbon fiber tow, applied in the field of test devices for the amount of carbon fiber wool, can solve the problems of long test time, neglect, large amount of fiber, etc., achieve low cost of use and maintenance, safe operation process, and simple test method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

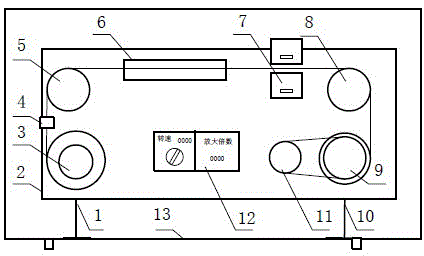

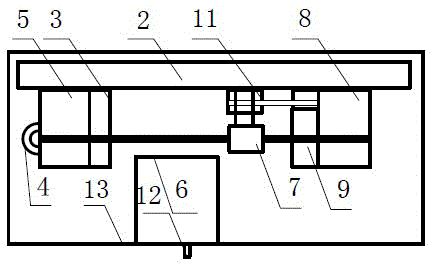

[0027] A test device for the amount of carbon fiber wool, such as figure 1 , figure 2 , comprising a test box 13, a fixing mechanism 2, a testing mechanism and a control mechanism 12, the testing box 13 is provided with a fixing mechanism 2 for fixing the testing mechanism, and the two ends of the fixing mechanism 2 are respectively supported by a support frame one 1 and a support frame two 10 , the test mechanism includes carbon fiber creel 3, porcelain eye 4, spreading roller 1, wool measurement mechanism 7, spreading roller 2 8, carbon fiber winding mechanism 9 and motor 11, carbon fiber creel 3, porcelain eye 4, spreading roller Yarn roller one 5 is set on the fixed mechanism 2 in sequence, and a wool yarn measuring mechanism 7 is arranged between yarn spreading roller 1 5 and yarn spreading roller 2 8, wool yarn measuring mechanism 7 includes a portable microscope, yarn spreading roller 2 8, carbon fiber winding The mechanism 9 is arranged on the fixed mechanism 2 in tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com