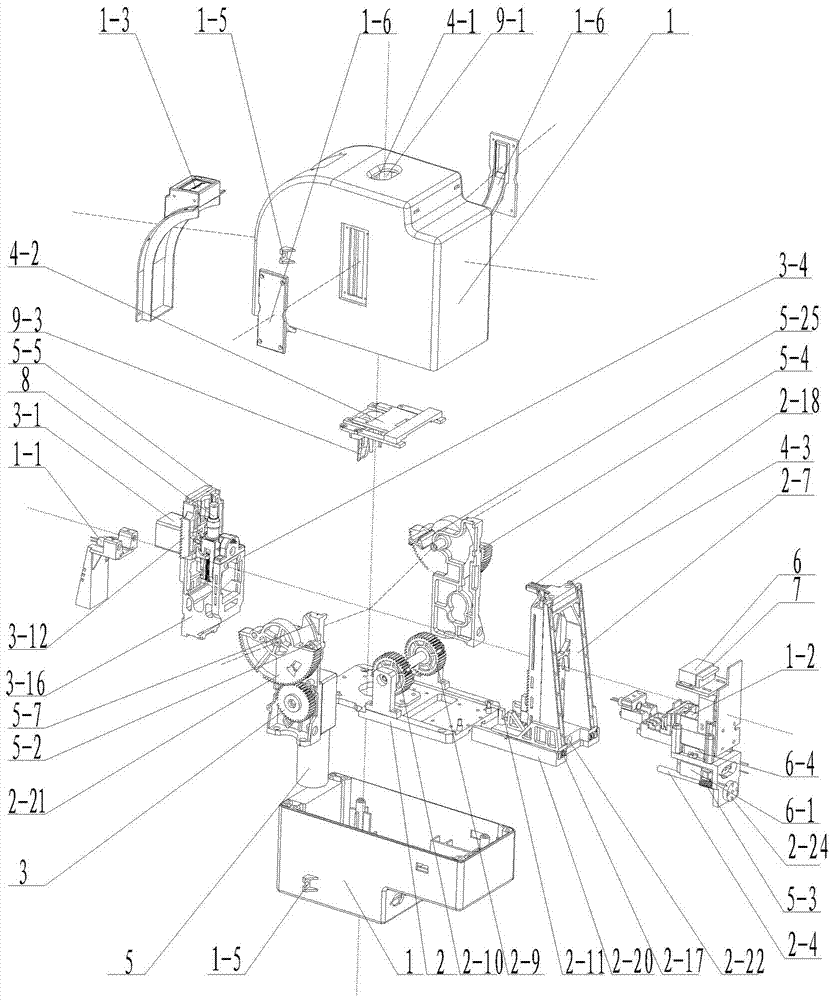

A system for moving up and down of an automatic detector for an integrated quantitative sampling and reagent addition device

An integrated technology for adding reagents, applied in the field of up and down moving systems of automatic detectors, can solve the problems of no detection device, affecting the test results, affecting the test results of the reagents, etc., and achieves the effect of fast response and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1 working process of the present invention:

[0096] The first is start-up detection: after the machine is powered on, the temperature sensor works, and the control unit obtains the real-time temperature in the cabin. When the temperature is equal to or higher than the preset minimum value, the machine heating device enters the standby state. When the temperature is lower than the preset minimum value When the heating system is working, the electric heater is energized and the heat is transferred to the heat sink. The fan installed on the heat sink drives the air to flow through the heat sink. The air duct is sent to the inside of the body to increase the temperature inside the body. When the temperature is equal to or higher than the preset maximum value, the electric heater and fan stop working; the temperature sensor ensures that the temperature inside the body is not lower than the preset temperature range.

[0097] Integrated quantitative sampling and re...

Embodiment 2

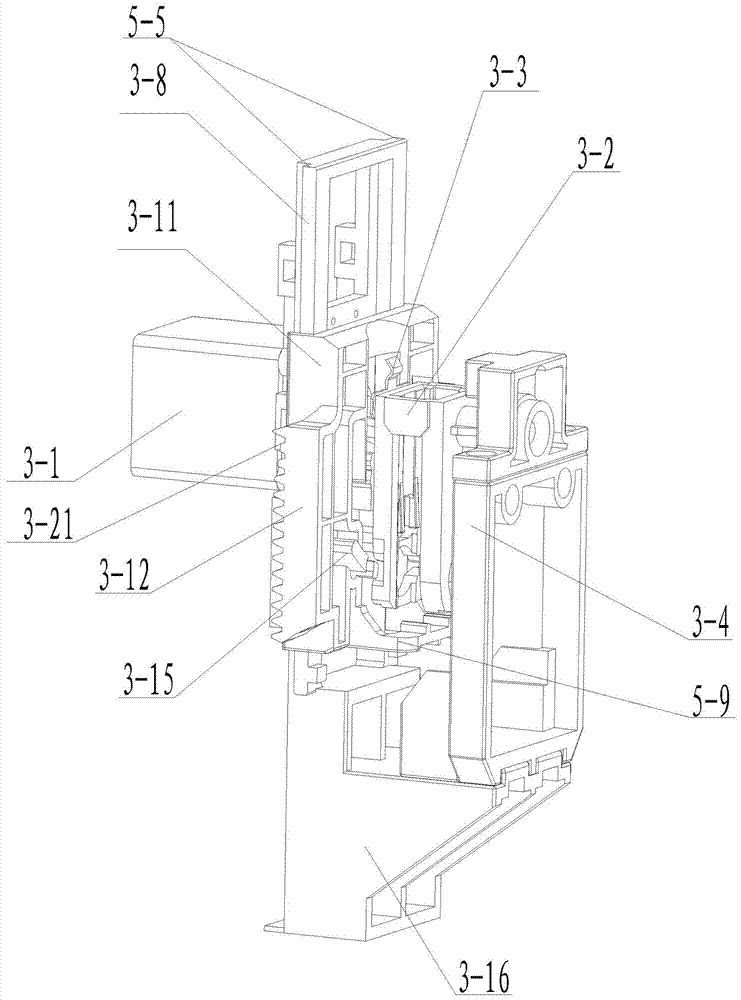

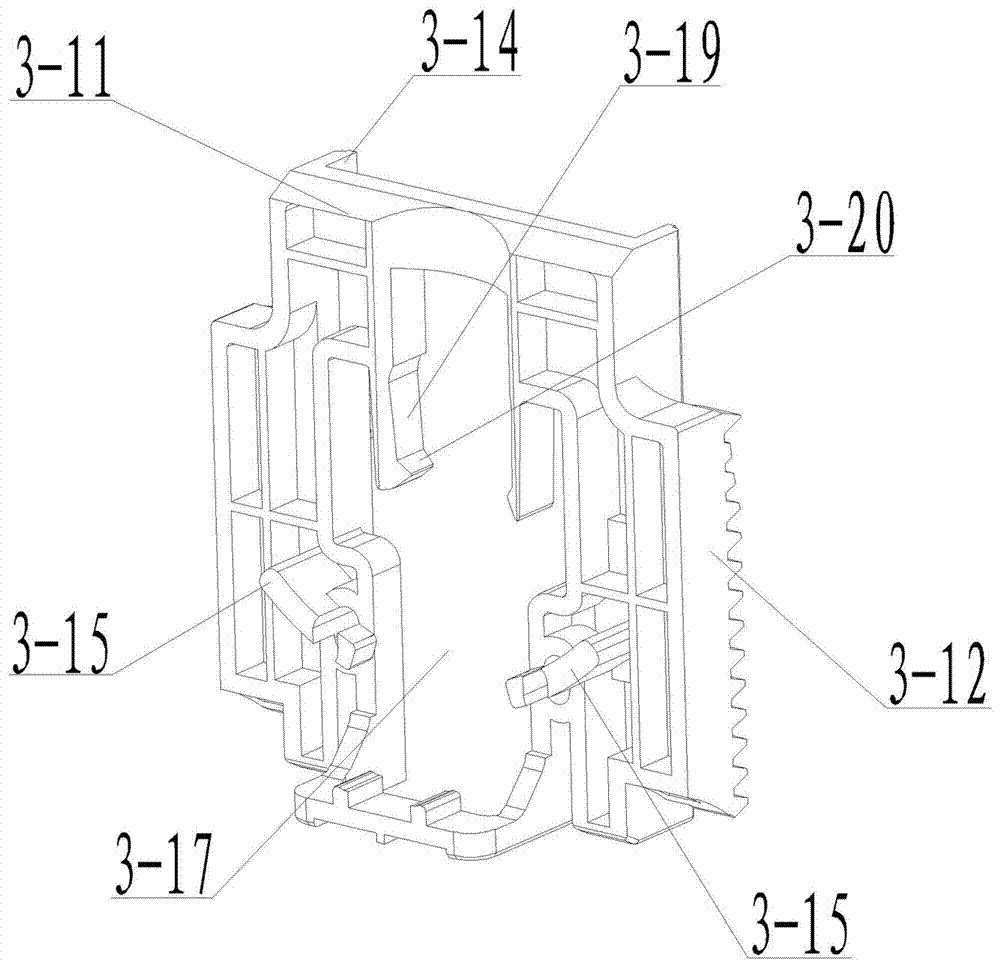

[0107] Embodiment 2: The difference from Embodiment 1 is that the light detection mechanism includes three light detection and detection devices. After reading the information of the integrated quantitative sampling and reagent device, the controller obtains which light detection is required to detect the liquid to be detected. A permanent magnet is arranged on the sampler bracket 3-2, and three magnetic sensors corresponding to the three light detection and detection devices are respectively arranged at the corresponding positions of the three light detection and detection devices. Driven by the motor 3-1, the integrated quantitative sampling and reagent adding device 8 is deflected to the optical path of the corresponding tube detection device, and the magnetic sensor is used to locate the position of the sampler bracket 3-2 to ensure the integrated quantitative sampling and adding reagent The detection position of the device 8 coincides with the detection optical path, and t...

Embodiment 3

[0108] Embodiment 3: The difference from Embodiment 1 is that the horizontal carriage 2-7 always gives a thrust to the horizontal carriage 2-7 through the support plate 2-2, the guide rod 2-4 and the compression spring 2-5, and the end cover 2 -24 is on the outside of the support plate 2-2, the length of the guide rod 2-4 is adjusted by the thread so as to adjust the thrust of the horizontal carriage 2-7, so that the horizontal carriage 2-7 is not easy to loosen during the action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com