Method for measuring uniform particle size based on auto-correlation algorithm

A particle size and measurement method technology, which is applied to the particle size measurement of beans, can solve the problems that cannot be popularized and used, time-consuming and cumbersome, expensive experimental instruments, etc., and meet the requirements of low external environment, low equipment cost, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

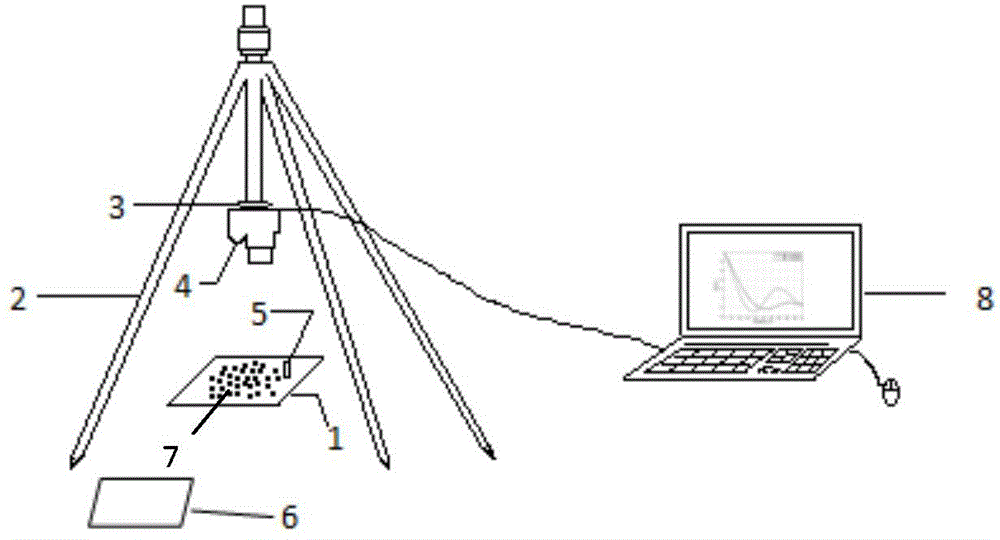

[0029] figure 1 A set of measuring equipment capable of realizing the measuring method of the present invention is shown, and the measuring equipment is composed of image acquisition equipment and a computer. The image acquisition device includes a black flat panel 1 , a tripod 2 , a level 3 , a digital camera 4 , a size calibration object 5 and a glass plate 6 ; the digital camera 4 is connected to a computer 8 .

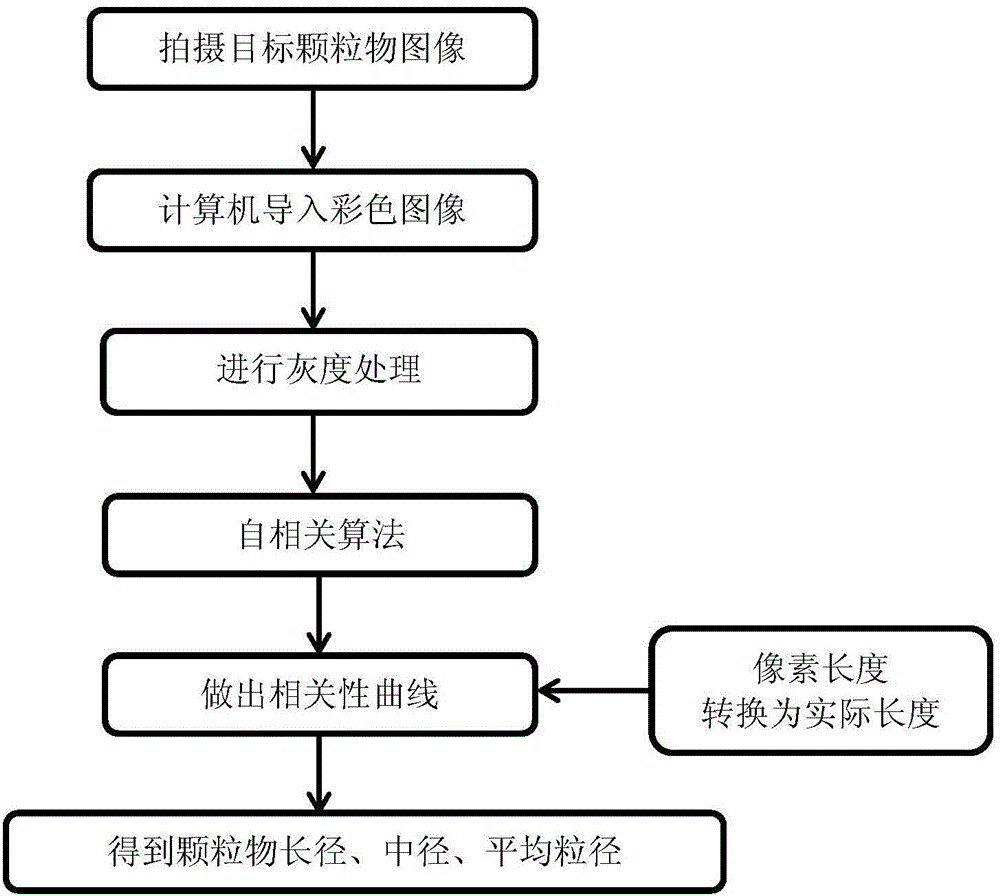

[0030] Such as figure 2 Shown, a kind of uniform particle size measuring method based on autocorrelation algorithm of the present invention comprises the following steps:

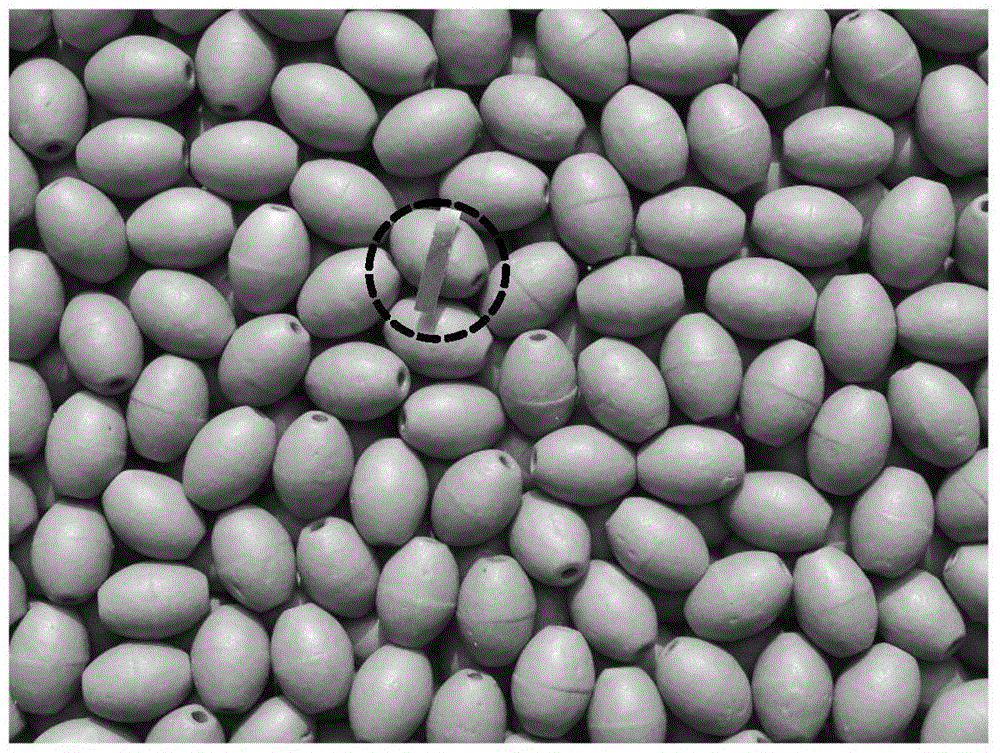

[0031] (1) Take an image of the target particle 7, taking beads as an example, specifically including the following sub-steps:

[0032] (1.1) Spread the target particle 7 on the black flat plate 1, flatten it with a glass plate 6, remove the glass plate 6 and place the size calibration object 5; in order to avoid affecting the subsequent image processing, the size calibration object 5 should ...

Embodiment 2

[0048] The method of the present invention is applied to measure sand, gravel and pebbles between 1-20mm in 11 groups of particle diameters, and equally utilizes figure 1 Measuring equipment shown. The measurement procedure is the same as that of Example 1. After step 2.2, 11 groups of grayscale images are obtained, 4 groups of which are as Figure 5 shown; after step 2.5, the corresponding correlation curve is obtained, such as Image 6 shown.

[0049] The long diameter, middle diameter and average particle diameter measured by the inventive method are compared with the results of long diameter, middle diameter and average particle diameter measured by digital calipers, and the comparison results are as follows: Figure 7 As shown, the horizontal axis represents the measurement result of the digital caliper, the vertical axis represents the particle size measured based on the autocorrelation algorithm in the present invention, the symbol circle represents the long diameter,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com