Ultra-oil-resistant and ultra-low-temperature-resistant photoelectric comprehensive cable for rail transit vehicle and production method for cable

A rail transit vehicle and optoelectronic integrated technology, which is applied in the field of ultra-oil-resistant and ultra-low temperature-resistant optoelectronic integrated cables for rail transit vehicles and its preparation, achieves the effects of light weight, increased flexibility, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

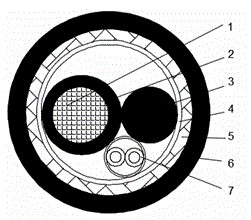

[0035] Such as figure 1 As shown, an oil-resistant and low-temperature resistant photoelectric integrated cable for rail transit vehicles includes a power transmission part, a signal control part, an optical transmission communication part, a shielding layer part and a sheath layer. The power transmission part is composed of conductor 1 extruded insulation 2, in order to improve the anti-oxidation and corrosion resistance of the conductor, tinning process is used for production. The signal control part is composed of ceramic silicon rubber refractory insulating wire core 7, the optical transmission communication part is composed of optical unit 3, conductor 1 is covered with insulating layer 2, and ceramic silicon rubber refractory insulating wire core is twisted with optical unit 3 to form cable core. The shielding layer part is composed of the shielding layer structure 5. In the interference section with a strong electromagnetic field, in order to prevent the induced curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com