SbSe-based nitrogen-doped nano-film material for PCRAM and preparation method for SbSe-based nitrogen-doped nano-film material

A technology of nano-film materials and phase-change memory, applied in the field of phase-change memory materials and their preparation, can solve the problems of memory data loss, negative effects on the human body and the environment, low crystallization temperature, etc., and achieves improved stability, fast crystallization speed, The effect of increasing storage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

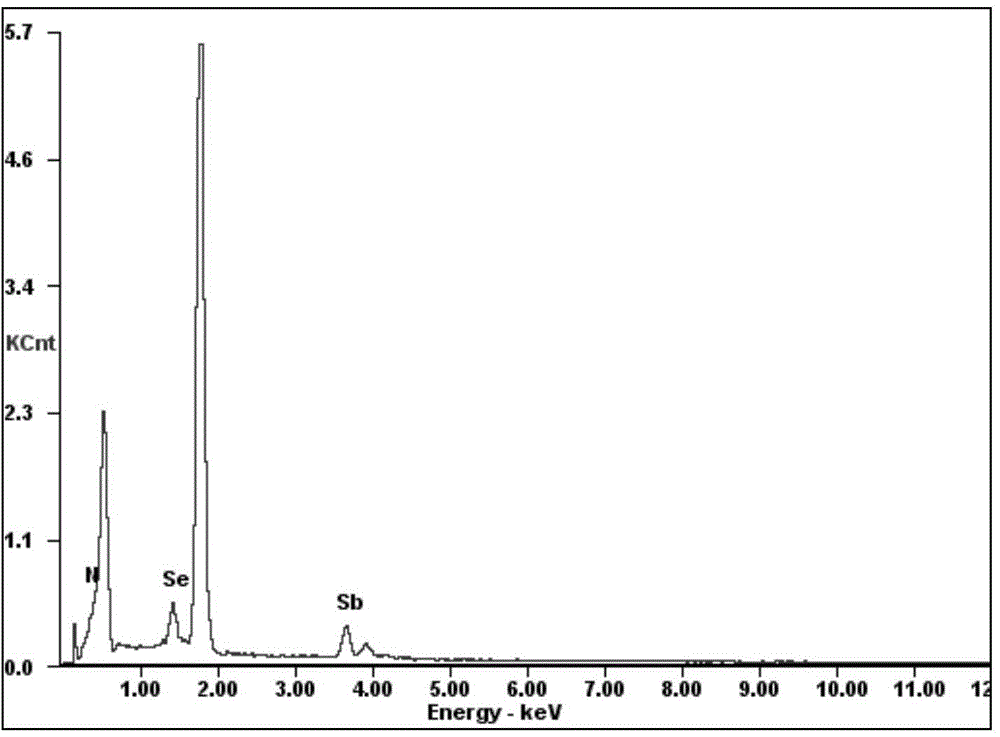

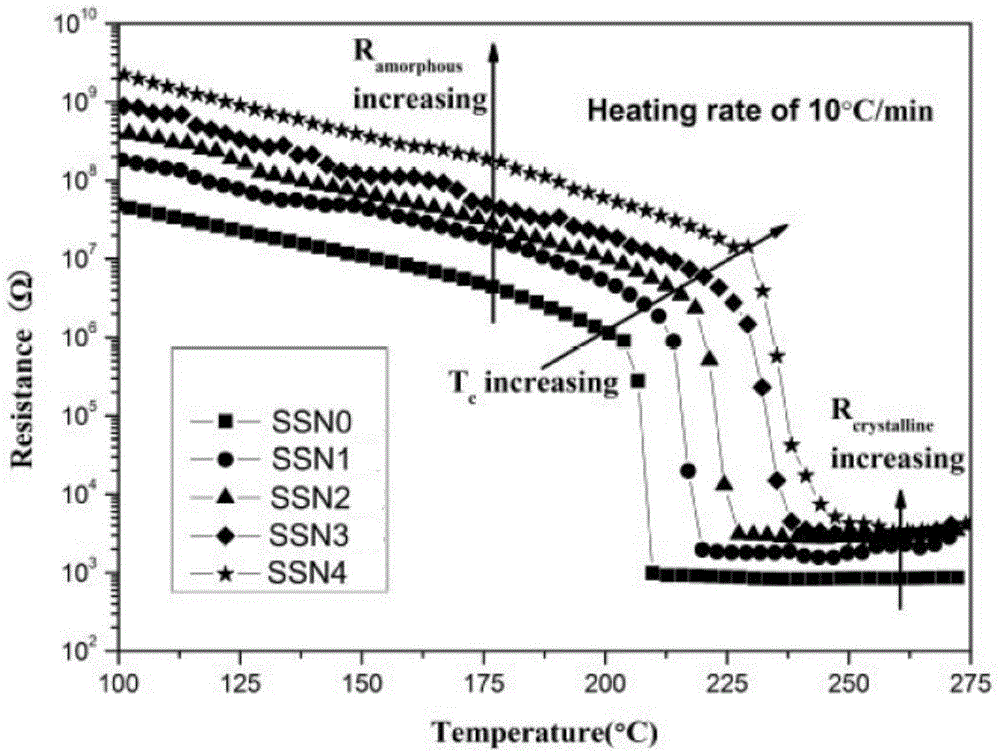

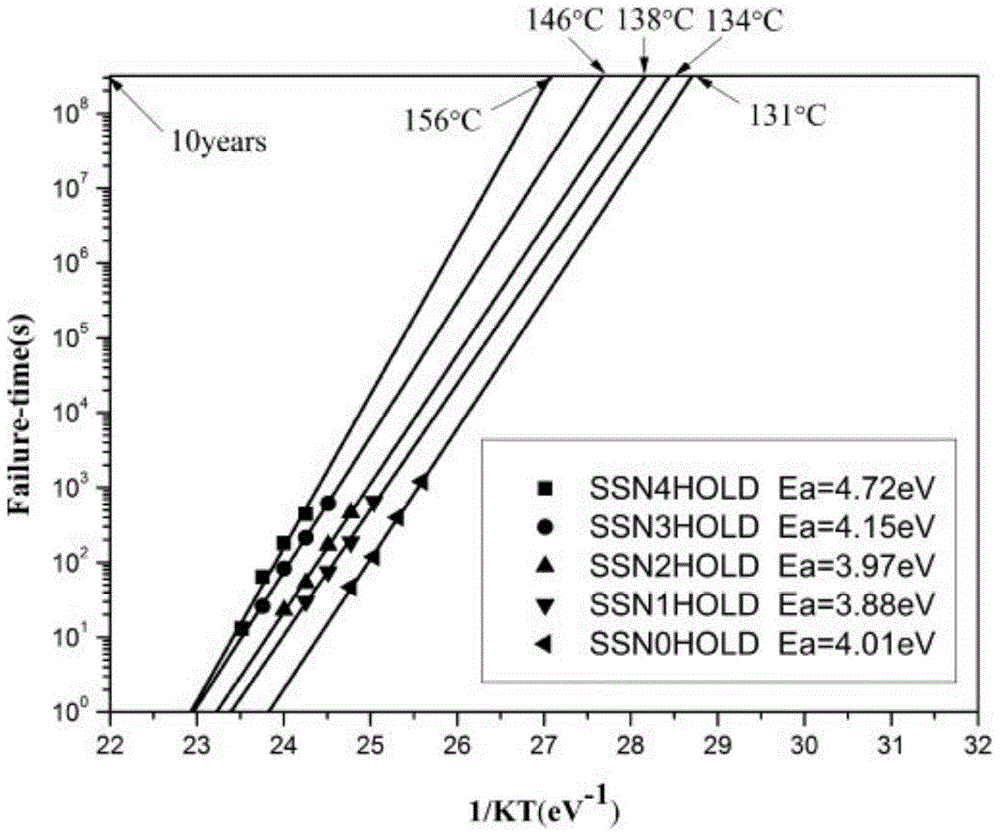

[0022] The general formula of the chemical composition of the SbSe-based nitrogen-doped nano-film material used for phase-change memory in this embodiment is (Sb 70 Se 30 ) x N 1-x , where x=0.69~0.75 (x=0.7392 in this embodiment).

[0023] The SbSe-based nitrogen-doped nano-film material is prepared by magnetron sputtering; high-purity nitrogen and high-purity argon are introduced during preparation, and the total gas flow of nitrogen and argon is 30 sccm, wherein the flow of nitrogen gas is 1 sccm; The ejection pressure is 0.15 Pa to 0.35 Pa, and the specific preparation method includes the following steps:

[0024] ①Substrate cleaning, cleaning the surface and back of the substrate to remove dust particles, organic and inorganic impurities. Select SiO with a size of 5mm×5mm 2 / Si (100) substrate, first ultrasonically clean the substrate in acetone (a purity of 99% or more) in an ultrasonic cleaner for 3 to 5 minutes, take it out and rinse it with deionized water; then ...

Embodiment 2)

[0034] The chemical composition formula (Sb 70 Se 30 ) x N 1-x Among them, x=0.7255.

[0035] The rest of the preparation method are the same as in Example 1, the difference is: step 3. when high-purity argon and high-purity nitrogen are introduced into the sputtering chamber, the Ar gas flow rate is set to be 28 sccm, N 2 The flow rate is 2 sccm.

Embodiment 3)

[0037] The chemical composition formula (Sb 70 Se 30 ) x N 1-x Among them, x=0.7150.

[0038] The rest of the preparation method are the same as in Example 1, except that: step 3. when high-purity argon and high-purity nitrogen are introduced into the sputtering chamber, the Ar gas flow rate is set to be 27 sccm, and the N 2 The flow rate is 3 sccm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap