Thread inspection method, thread inspection device, thread manufacturing method, thread package, and thread module

An inspection method and thread technology, which are applied in the fields of thread inspection, thread inspection device, thread manufacture, thread package and thread module, can solve the problem of enlarging the width of the circumscribed rectangle, rising costs, and long data processing time, etc. problem, to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

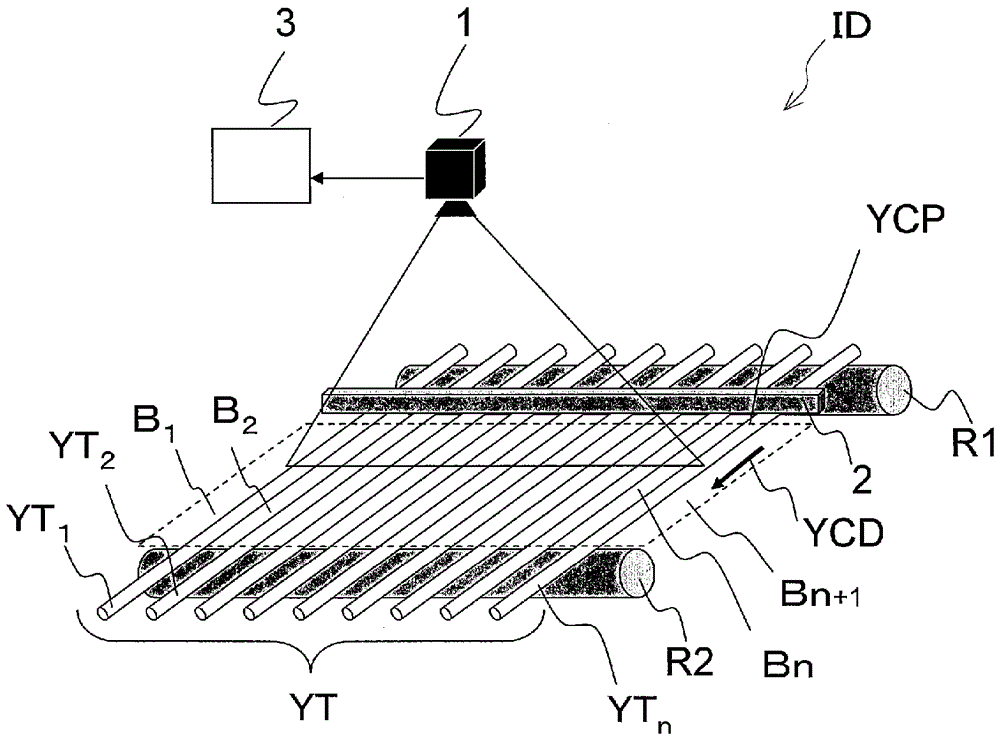

[0072] A first embodiment of the present invention will be described.

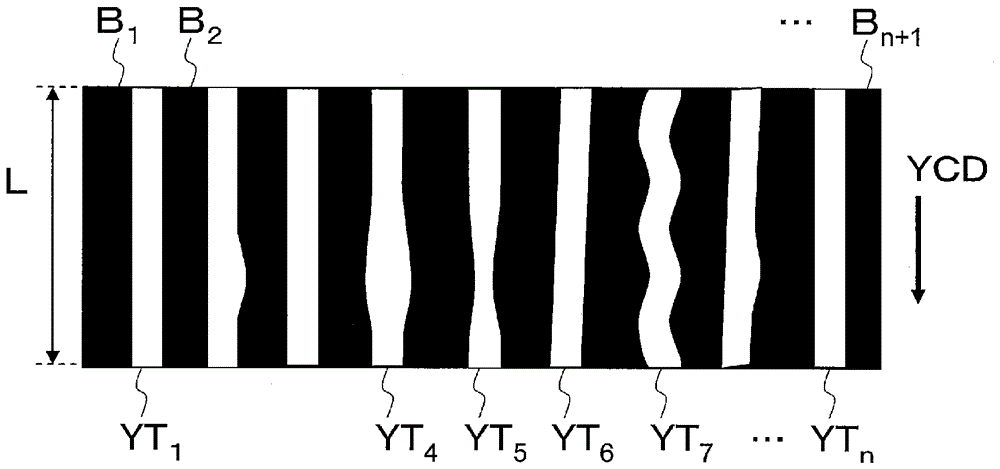

[0073] In the silk thread inspection method of the present invention, a photographing unit is used to photograph the running silk thread, and a data processing unit is used to perform data processing on the obtained image data. This data processing includes: (a) a process of calculating a plurality of line widths (hereinafter, sometimes referred to as "line width data set") in a predetermined section in the traveling direction from the image data of the running thread (hereinafter referred to as the process A), (b) the process of calculating the line width deviation from the obtained line width data set (hereinafter referred to as process B), and (c) the process of comparing the line width deviation with the first threshold value (hereinafter referred to as process C ).

[0074] In the image data obtained by the imaging means, the thread portion and the background portion around the thread are imaged, and...

no. 2 approach

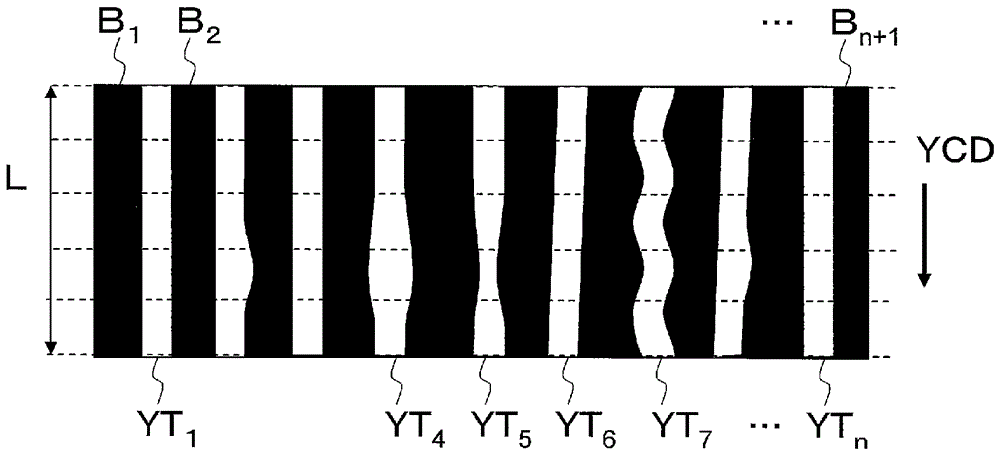

[0093] In the second embodiment of the inspection method of the present invention, in addition to the inspection of the presence or absence of a wire defect based on the above-mentioned first embodiment of the present invention, the state of the wire defect can be inspected. In the second embodiment, in addition to the above-mentioned data processing, the data processing also includes: calculating the width of the circumscribed rectangle and / or the width of the inscribed rectangle of the above-mentioned running wire in a predetermined section of the running direction of the running wire The process (hereinafter referred to as process D) and / or the process of calculating the representative value of the line width according to the line width data set (hereinafter referred to as the process E), and the representative value of the line width and the width of the circumscribed rectangle and / or the inscribed rectangle The process of breadth comparison (hereinafter referred to as proc...

no. 3 approach

[0105] In the third embodiment of the present invention, in addition to the above-mentioned first embodiment of the present invention, the data processing further includes: calculating the circumscribed rectangle width and A process of calculating / or the width of the inscribed rectangle (process D), and a process of comparing the pre-designed line width with the above-mentioned circumscribed rectangle width and / or the above-mentioned inscribed rectangle width (process I).

[0106]As described above, in process D, two imaginary parallel lines circumscribing the thread portion of the image data based on the traveling direction YCD of the thread in the obtained image data are drawn, and the width of the imaginary line is defined as a circumscribed rectangle. Width to calculate. Also, similarly, two imaginary parallel lines inscribed in the silk line portion of the image data are drawn, and the width of the imaginary lines is calculated as the inscribed rectangle width.

[0107] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com