A method for fabricating a thin film transistor

A technology of thin-film transistors and oxide semiconductors, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of limited material combinations, achieve improved resolution, low sub-threshold slope, and reduce the size of transistors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

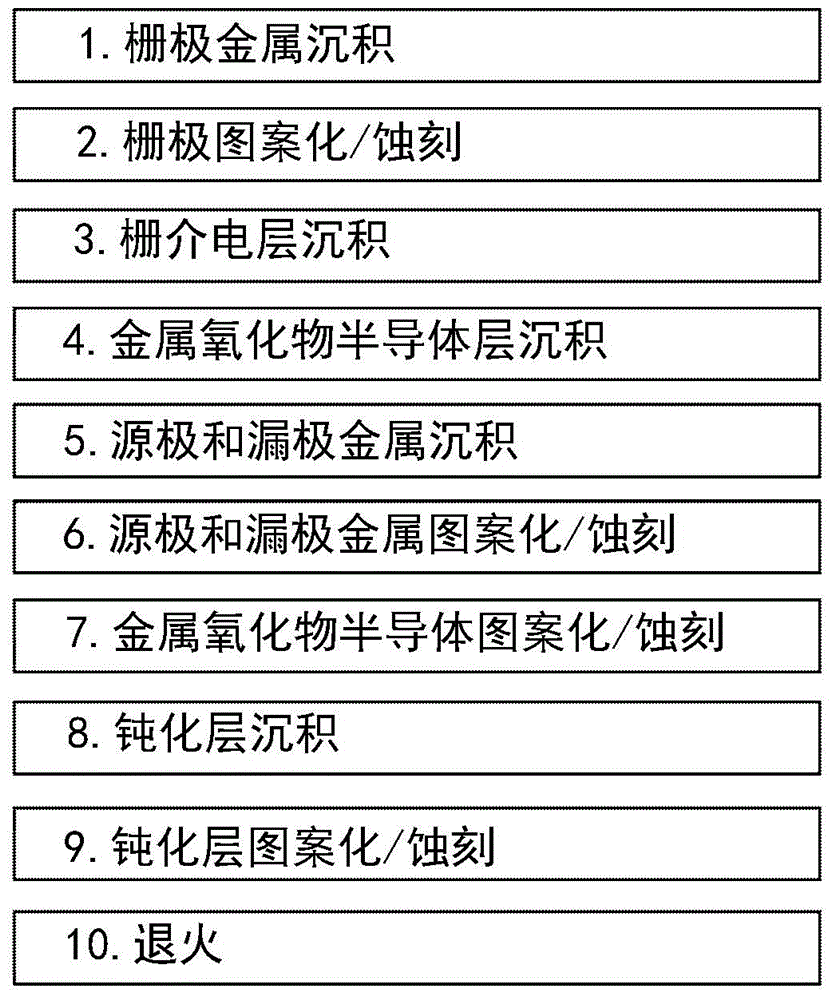

Method used

Image

Examples

Embodiment Construction

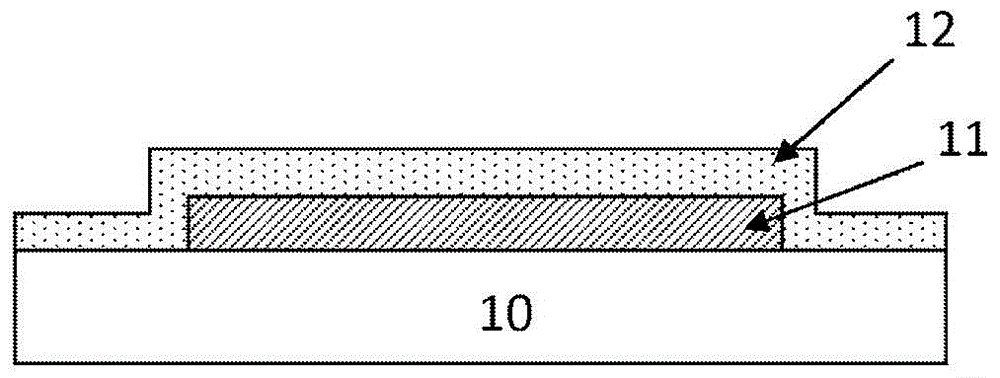

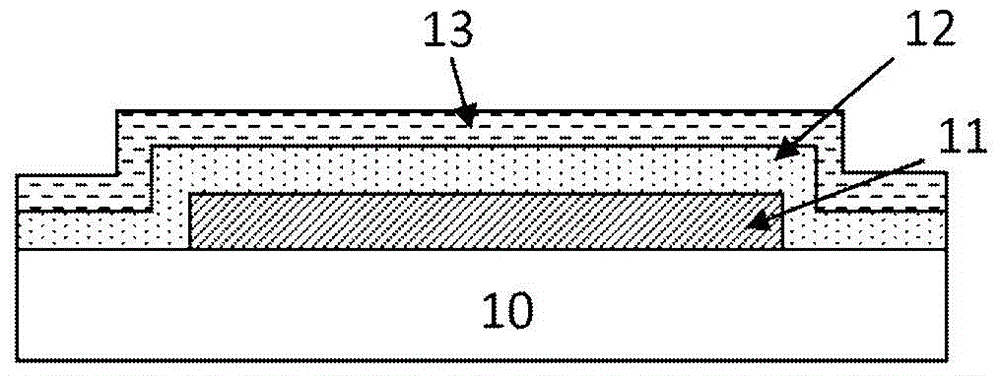

[0027] Detailed Description of Preferred Embodiments

[0028] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the invention and practice of specific embodiments. However, it is understood that the invention may be practiced without these specific details. In other instances, well-known methods, procedures and techniques have not been described in detail so as not to obscure the present invention. While the invention has been described in terms of particular embodiments and with reference to certain drawings, the invention is not limited thereto. The drawings included and described herein are schematic and do not limit the scope of the invention. It should also be noted that in the drawings, the size of some of the elements may be exaggerated for illustrative purposes and therefore not drawn on scale.

[0029] Moreover, the terms "first", "second", "third", etc. in the specification are used to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap