An improved profile extruder with closed pressurized oil supply

An improved extruder technology, which is applied in the direction of presses, mechanical equipment, fluid pressure actuators, etc., to achieve the effects of reasonable structure, high conveying efficiency, and saving production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

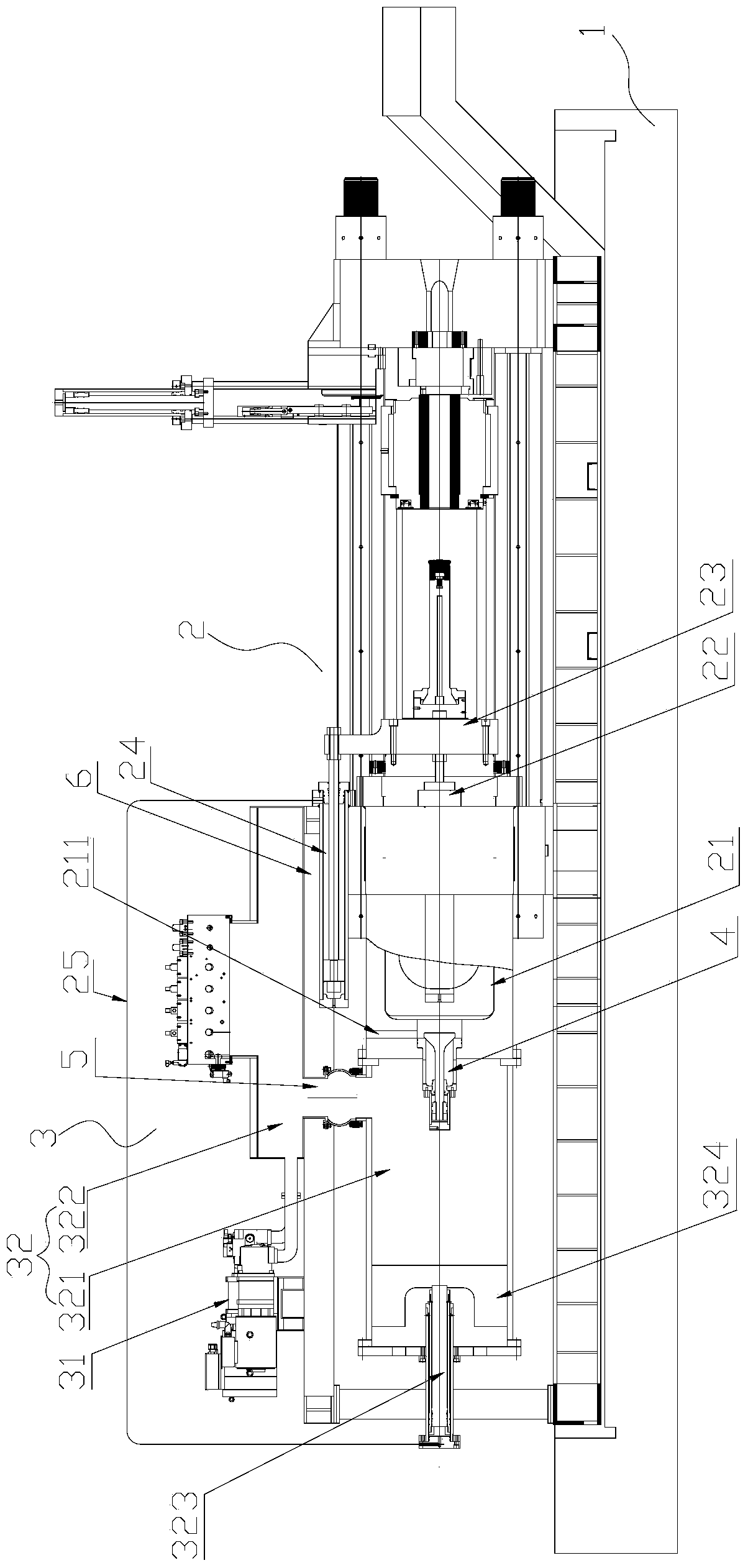

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] refer to figure 1 The improved type shown is a closed pressurized oil supply profile extrusion machine, including a fixed seat 1, an extrusion mechanism 2 and an oil supply system 3, and the extrusion mechanism 2 includes a main cylinder 21 and an auxiliary cylinder 22 and pressure beam 23; the oil supply system 3 includes an oil pump group 31 and an oil storage tank 32, the oil storage tank 32 supplies oil to the master cylinder 21 through a filling valve 4, and the oil storage tank 32 is composed of a A sealed pressurized oil cylinder 321 and a sealed return oil tank 322 are formed. The pressurized oil cylinder 321 is fixed at one end of the master cylinder 21 and fixed as one with the master cylinder 21. The return oil tank 322 is located above the pressurized oil cylinder 321. A hydraulic oil flow channel 5 is provided between the oil return tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com