Online-typed wire rod skin processing system

A processing system and wire rod technology, applied in metal extrusion cleaning equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to control the degree of phosphating, large space occupation, uneven phosphating, etc. High production efficiency and the effect of prolonging the phosphating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

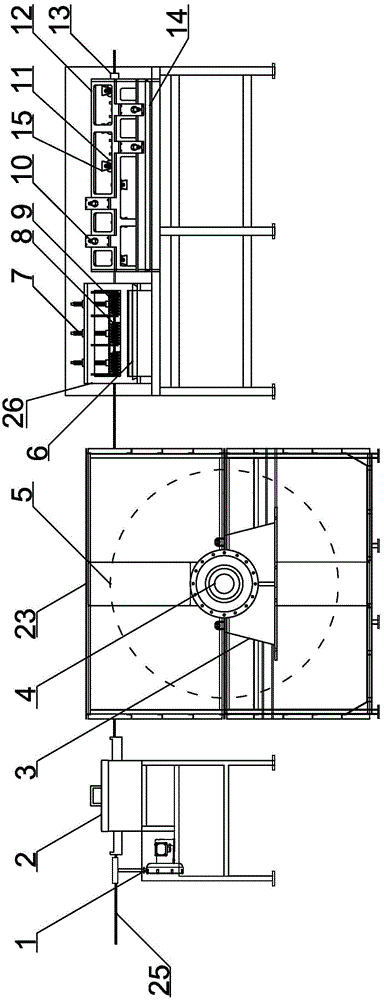

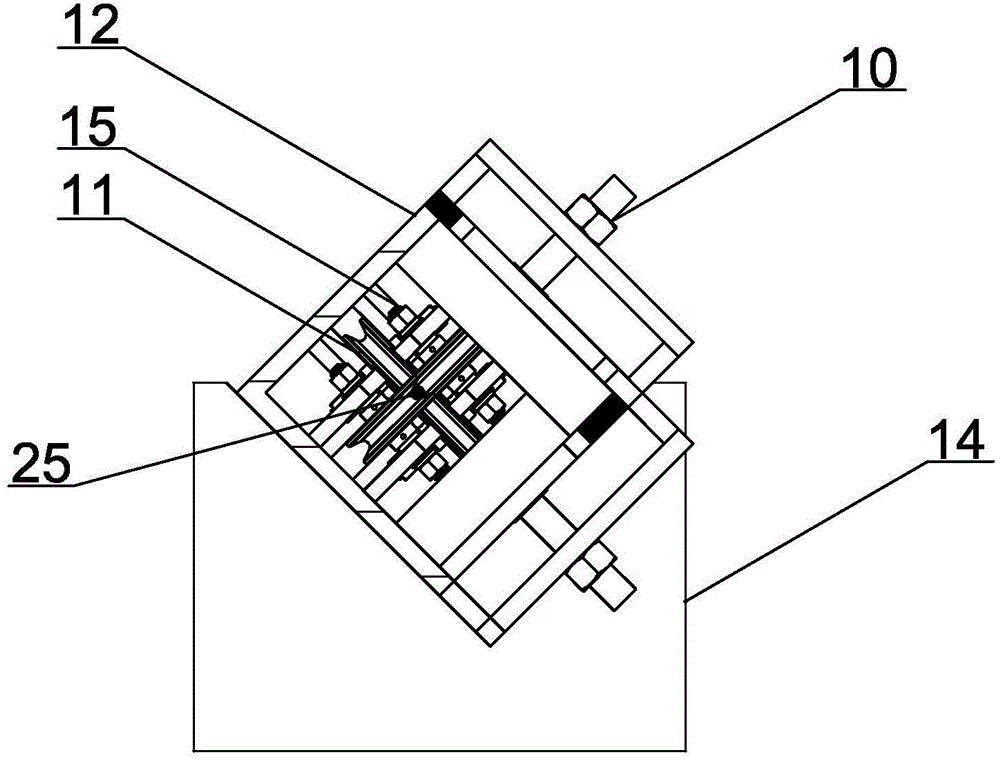

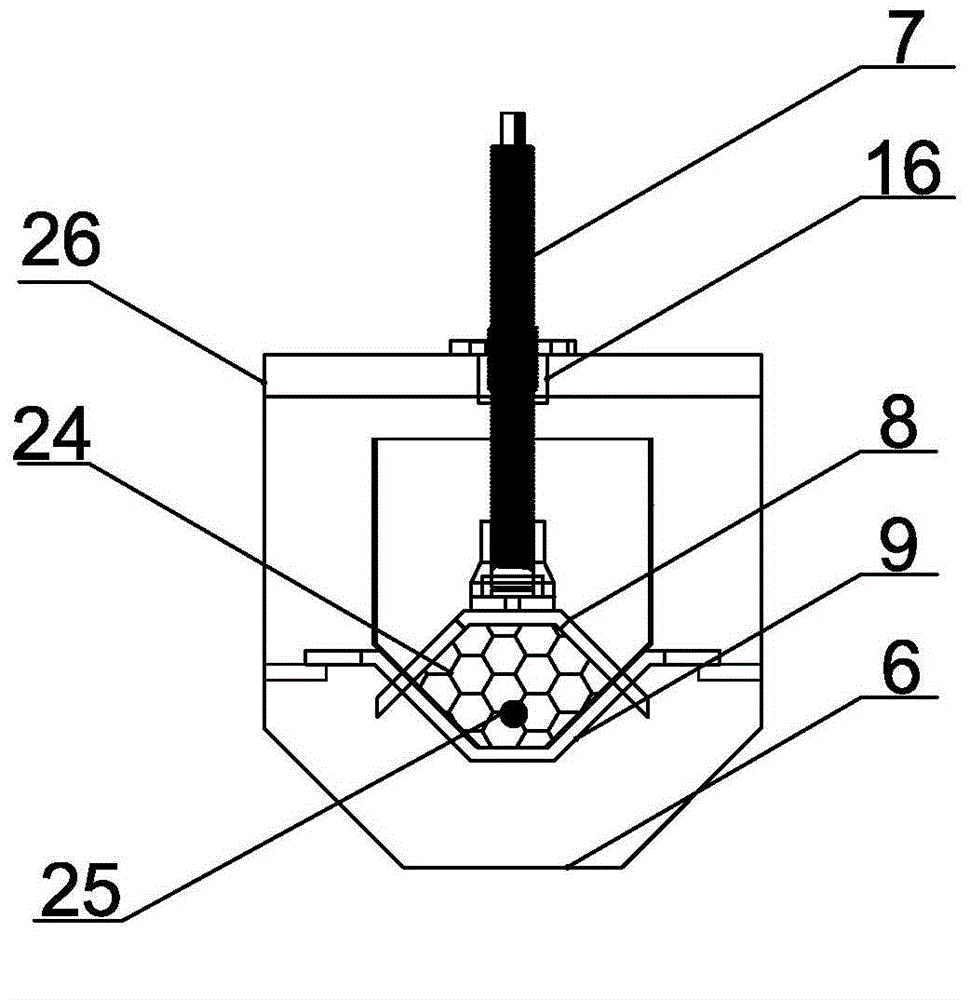

[0019] Such as figure 1 As shown, an online wire skin treatment system of the present invention includes a peeling mechanism, a derusting mechanism, a phosphating mechanism and a saponification mechanism in sequence according to the order in which the wire 25 passes. Such as figure 1 and figure 2 As shown, the peeling mechanism is used to remove the skin on the surface of the wire 25, including a housing 12, the housing 12 is rectangular, and the left and right ends of the housing 12 have a discharge end and a feed end for passing through the wire 25, and the feed A guide shaft 13 is arranged outside the end, and the guide shaft 13 is used to adjust the position of the wire 25 so that the wire 25 enters the housing 12 perpendicular to the end face of the feeding end of the housing 12 . Multiple sets of pressing structures are arranged side by side inside the housing 12, and two sets are selected in this embodiment. Each group of pressing structures includes at least two pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com