Spindle driving device of vertical type powerful spinning machine and driving method

A powerful spinning and spindle-driven technology, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of reducing the mechanical efficiency of spinning machines, slow switching of spindles, and low efficiency, so as to save manpower and improve Mechanical efficiency, reducing the effect of the transmission link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

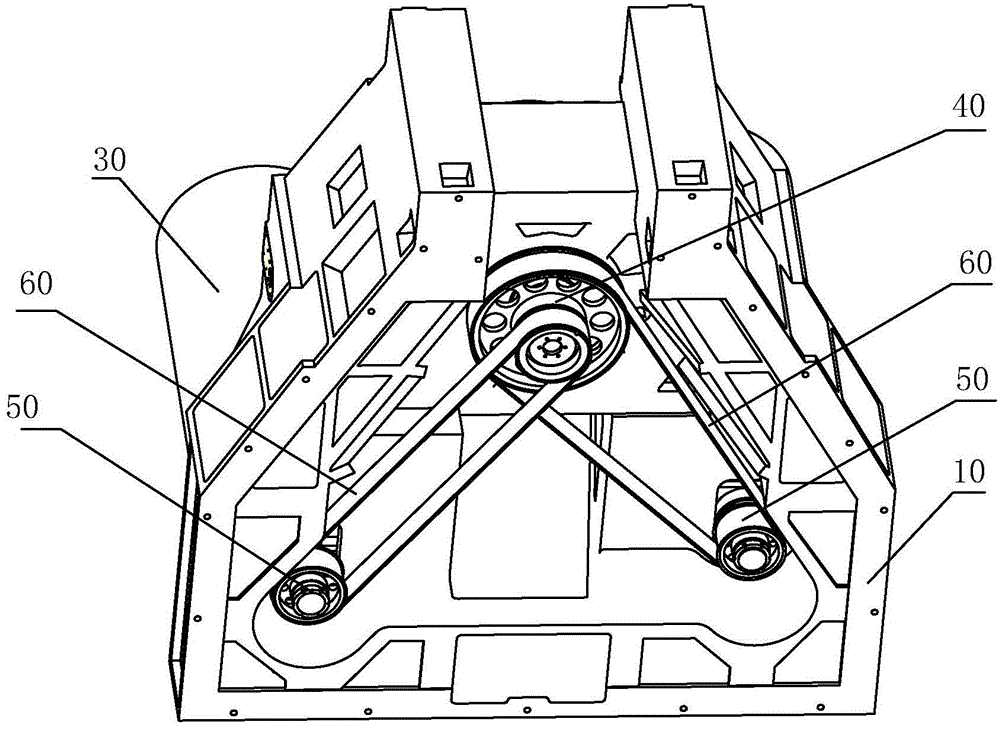

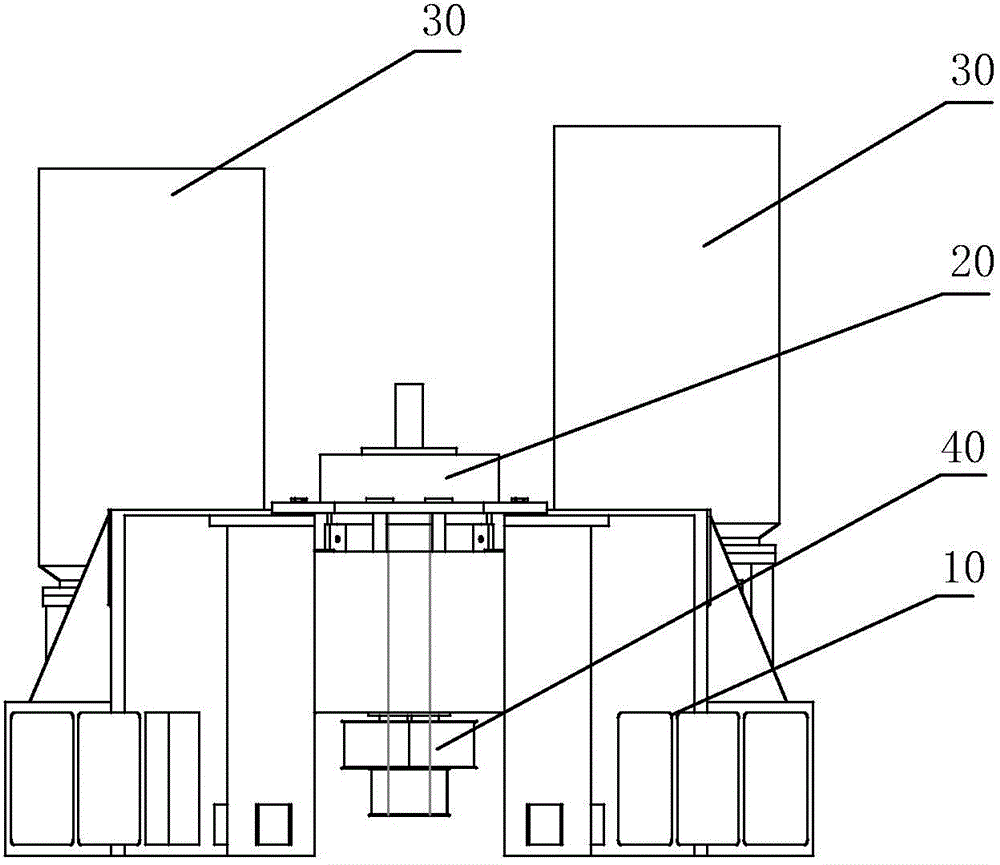

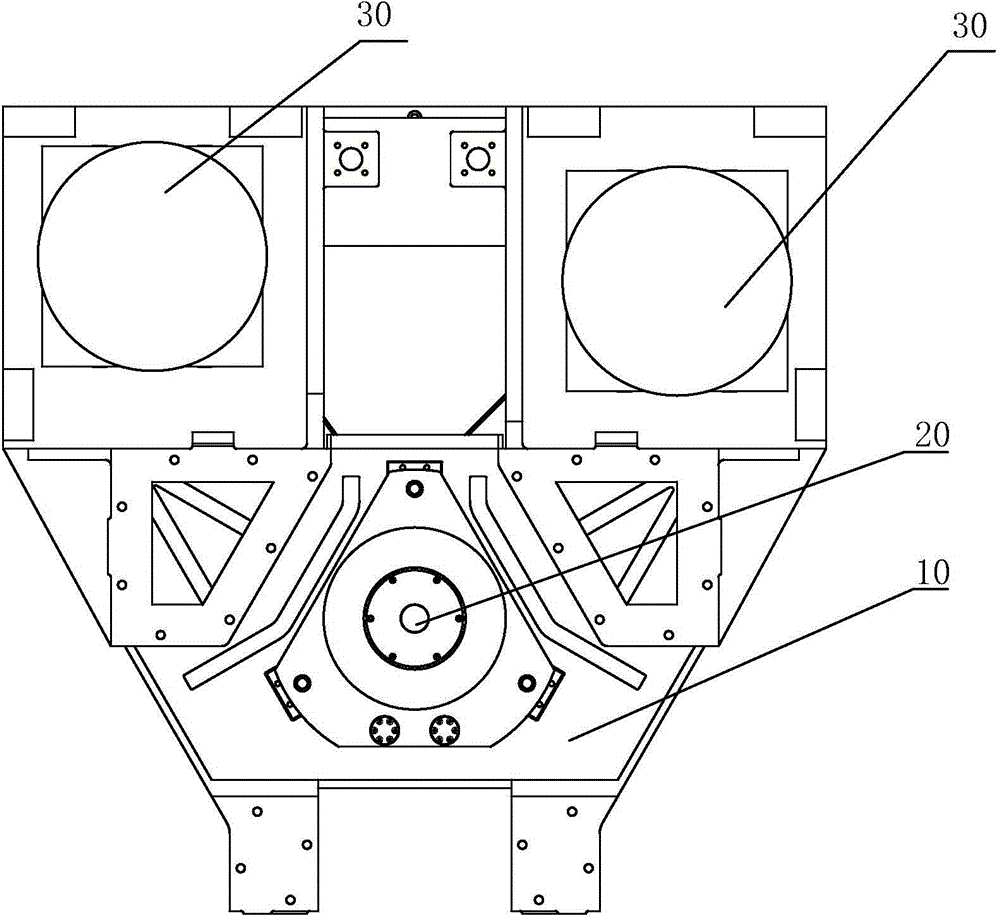

[0027] Such as Figure 1 to Figure 4 As shown, the main shaft driving device of the vertical powerful spinning machine of this embodiment includes: a bed 10, a main shaft 20, multiple sets of drive motors 30, and a control system for controlling the drive motors 30 (not shown in the figure) ), the spindle 20 is vertically mounted on the bed 10, the multiple groups of drive motors 30 are also vertically mounted on the bed 10, and the output end of each group of the drive motors 30 is mounted with a first With a pulley 50, a second pulley 40 is installed at the bottom of the main shaft 20, and each group of the first pulley 50 and the second pulley 40 are connected by a flexible transmission body 60. The diameters of the positions on the second pulley 40 corresponding to different flexible transmission bodies 60 are different from each other. Specifically, different flexible transmission bodies 60 are connected to different positions of the second pulley 40, and the diameters at...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that the diameters of the second pulley 40 corresponding to the positions of the flexible transmission bodies 60 are all the same, while the diameters of the multiple groups of the first pulleys 50 are different. The multiple sets of the first pulley 50, the flexible transmission body 60, and the second pulley 40 constitute different reduction ratios, so that the driving motor 30 provides different rotation speeds for the main shaft 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com