Dynamic control method and device for electromagnetic stirring position at solidification end in continuous casting of steel

A technology of electromagnetic stirring and solidification end, applied in the field of continuous casting production control of iron and steel metallurgy, can solve the problems of affecting temperature and thickness, maintain stability, and the effect of electromagnetic stirring at the end of solidification is not obvious, and achieve the effect of improving internal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

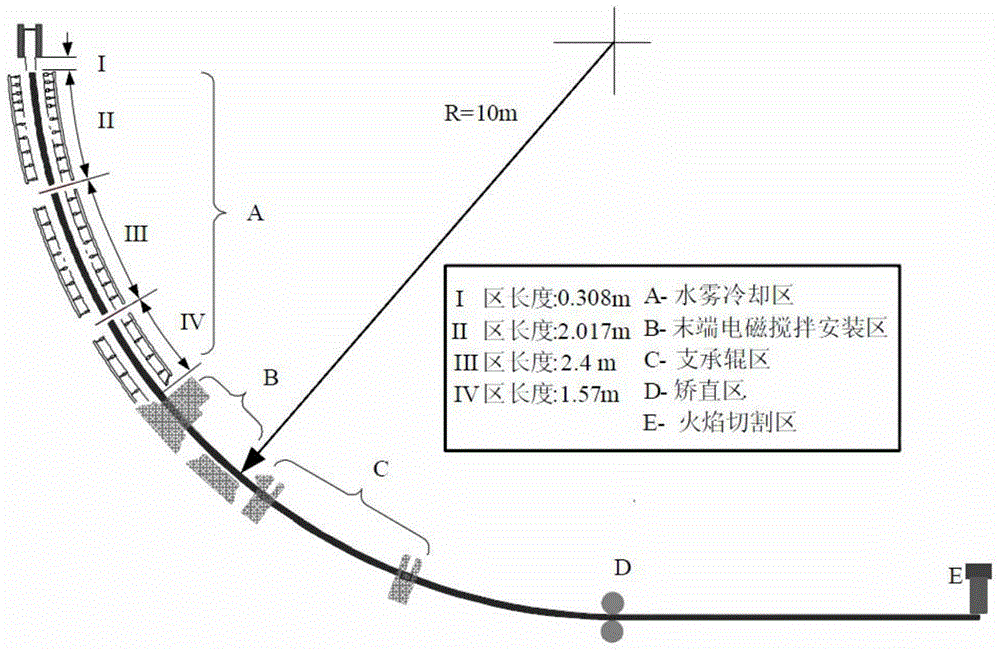

[0032] Such as figure 1 The billet continuous casting machine of a steel mill in China shown has ten streams, including the crystallizer area and four secondary cooling areas (such as figure 1 Zone I, Zone II, Zone III and Zone IV shown) and an air-cooled zone, in which the crystallizer has a total height of 0.9m and an effective height of 0.8m. The lengths of secondary cooling zone 1 to secondary cooling zone 4 are 0.308m, 2.071m, 2.4m and 1.57m respectively. The billet size is 160mm×160mm.

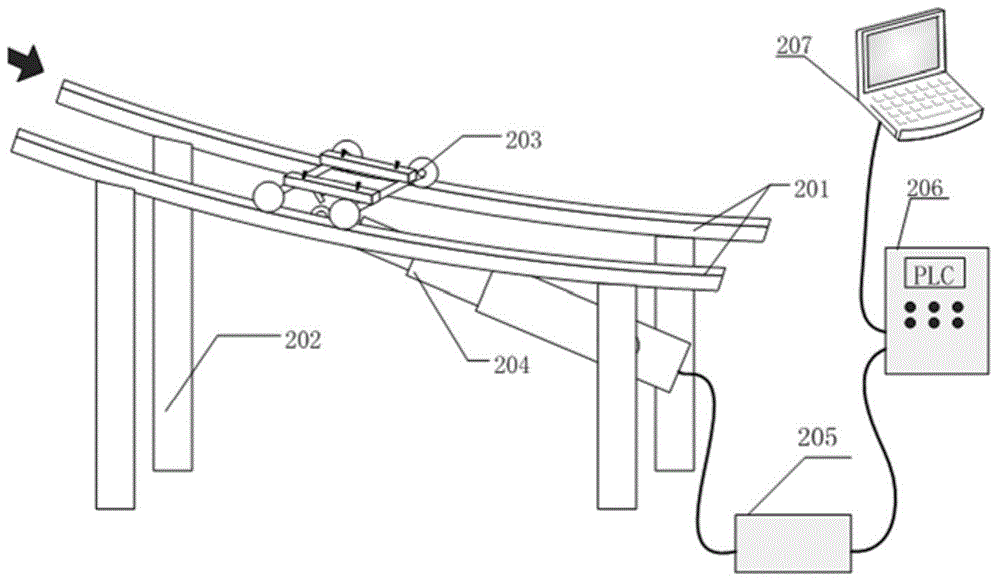

[0033] In this embodiment, the dynamic control device for the electromagnetic stirring position at the solidification end of steel continuous casting is specially designed for the dynamic control method of the electromagnetic stirring position at the solidification end of steel continuous casting implemented on the billet continuous caster figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com