A device and method for processing arc-curved grooves

A curved and arc-shaped technology, applied in the field of groove processing, can solve the problems of track unevenness, high equipment requirements, and impact on cutting quality, and achieve the effect of reducing construction and production costs, direct economic benefits, and compact structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

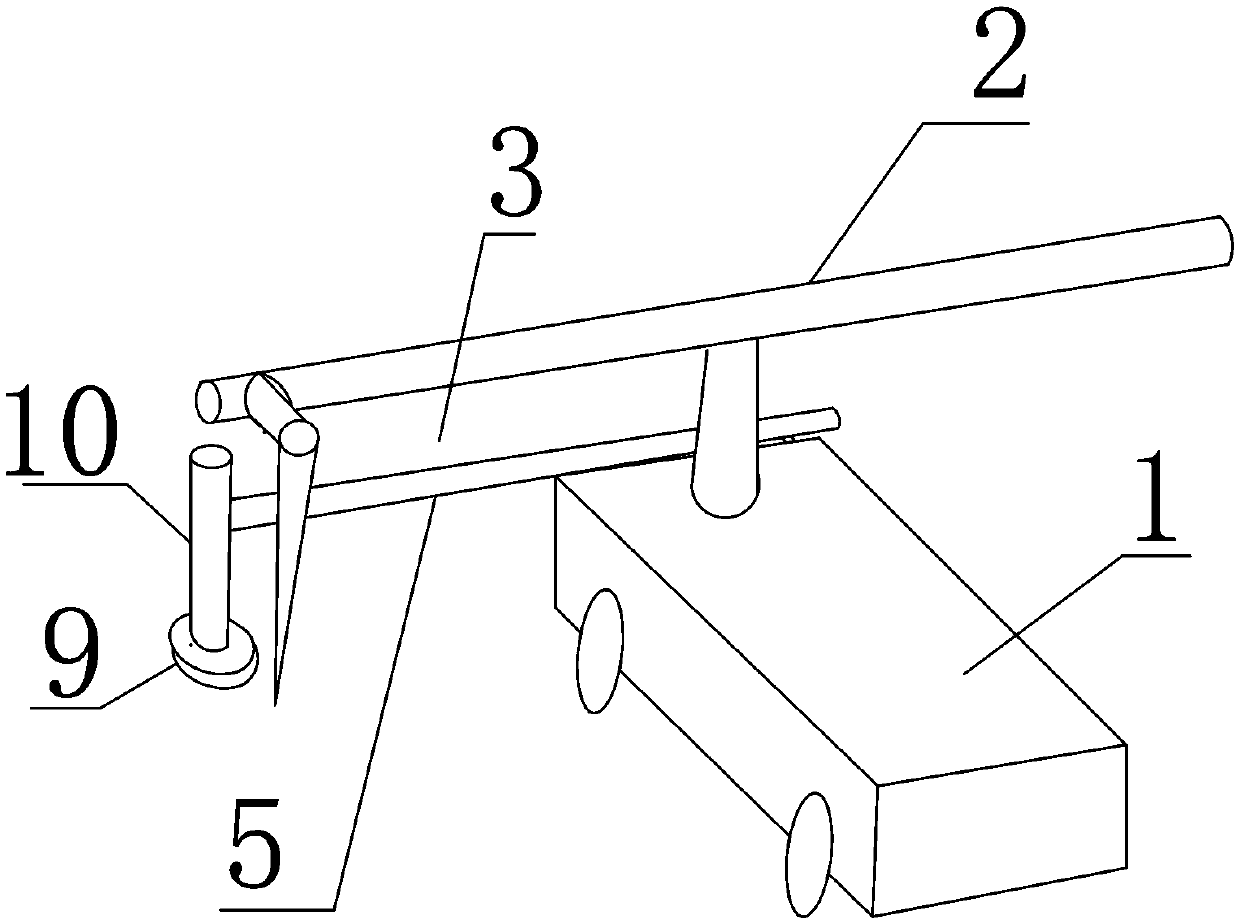

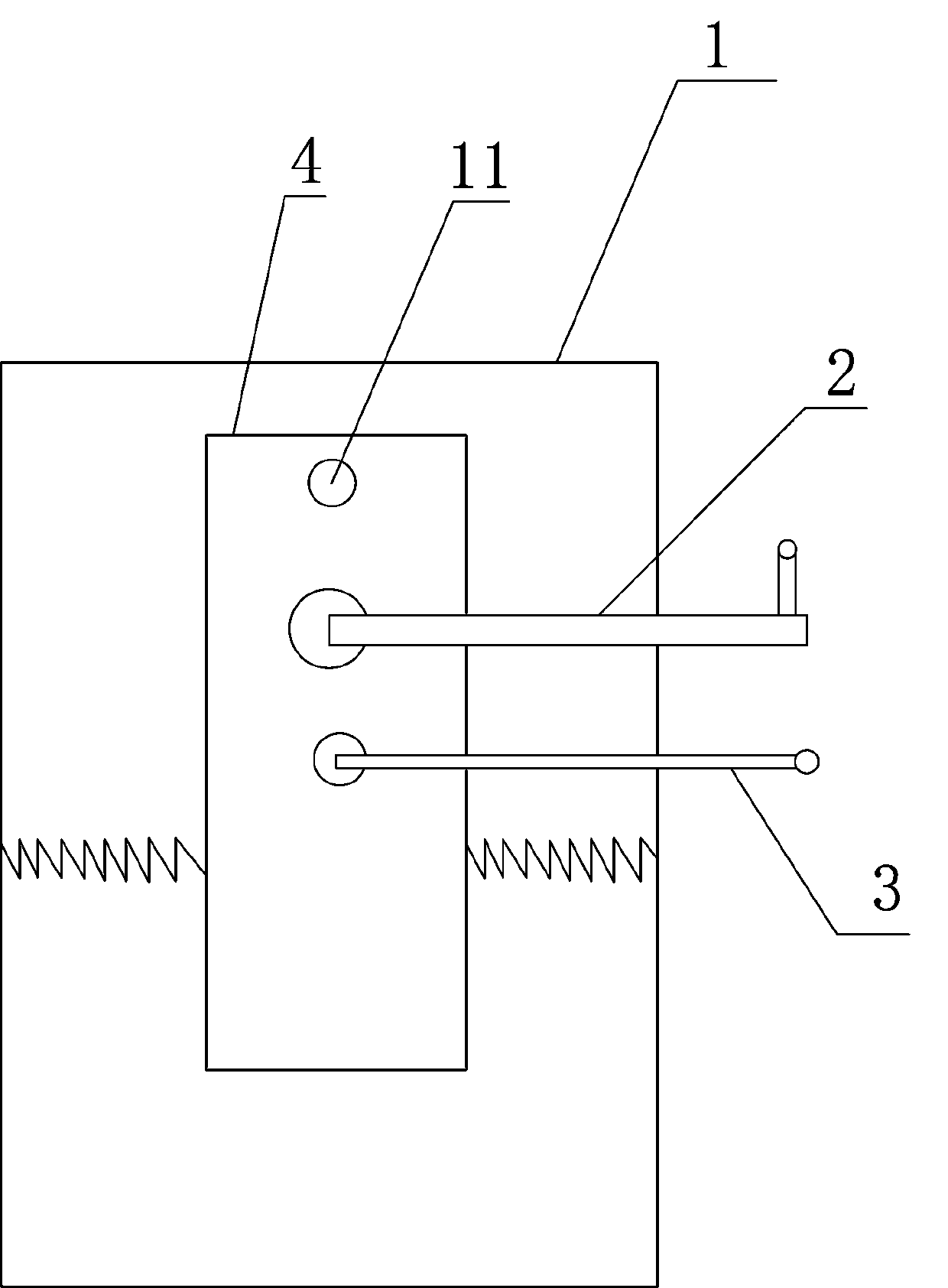

[0027] combine figure 1 , a device for processing arc-shaped curved grooves includes a mobile trolley 1, and a cutting part 2 and a limiting part 3 are arranged on the mobile trolley 1;

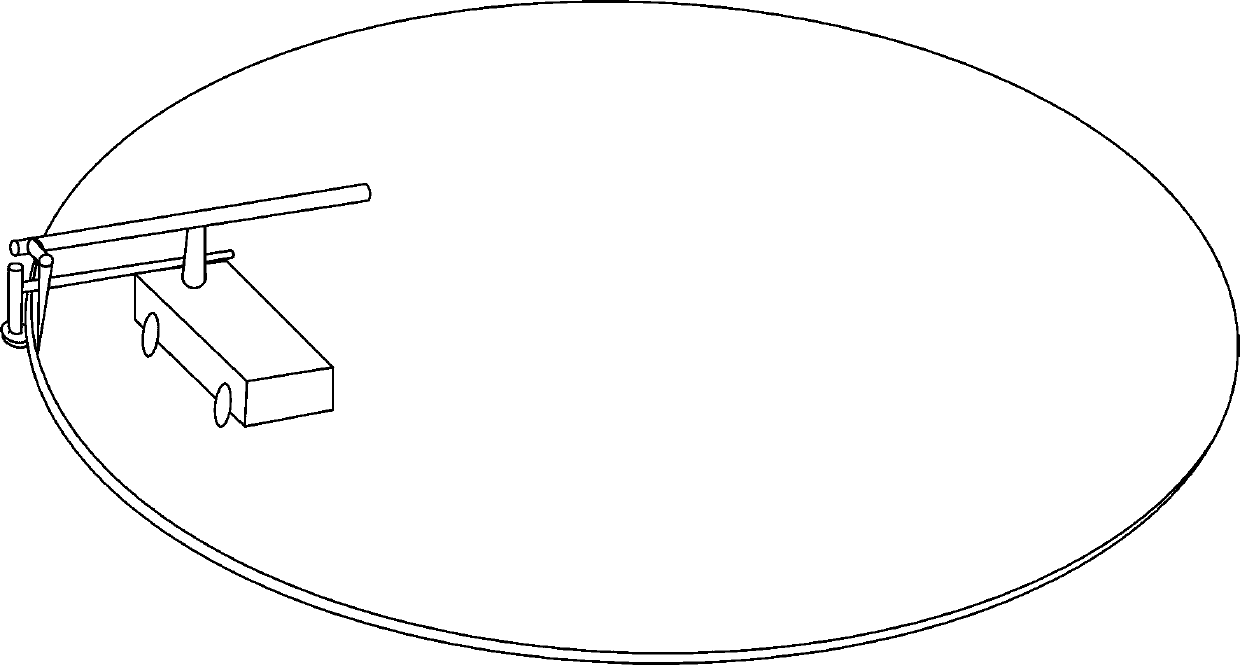

[0028] The position-limiting part 3 comprises a clamping part and a connecting rod 5 that connects the clamping part to the mobile trolley 1. The clamping part comprises a guide bearing 9 and an adjusting connecting rod 10 connected to the guiding bearing 9. The adjusting connecting rod 10 and The connecting rod 5 is connected, and the guide bearing 9 is in contact with the edge of the part to be processed, and the cutting track is limited. Preferably, the front wheel of the moving trolley 1 is a directional wheel, and the rear wheel is a universal wheel. The guide bearing 9 is adjusted by the connecting rod 10 Drive the connecting rod 5 to realize the limit to the trailing wheel moving track, during work, if figure 2 In the process, the guide bearing 9 is placed on the edge of the part to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com