A kind of heating method of copper-containing low-alloy steel

A low-alloy steel, heating method technology, applied in the field of steel rolling, can solve the problems of affecting output, shutdown of rolling mills, not solving "copper brittleness", etc., to achieve the effect of easy removal, inhibition of melting, and reduction of enrichment amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

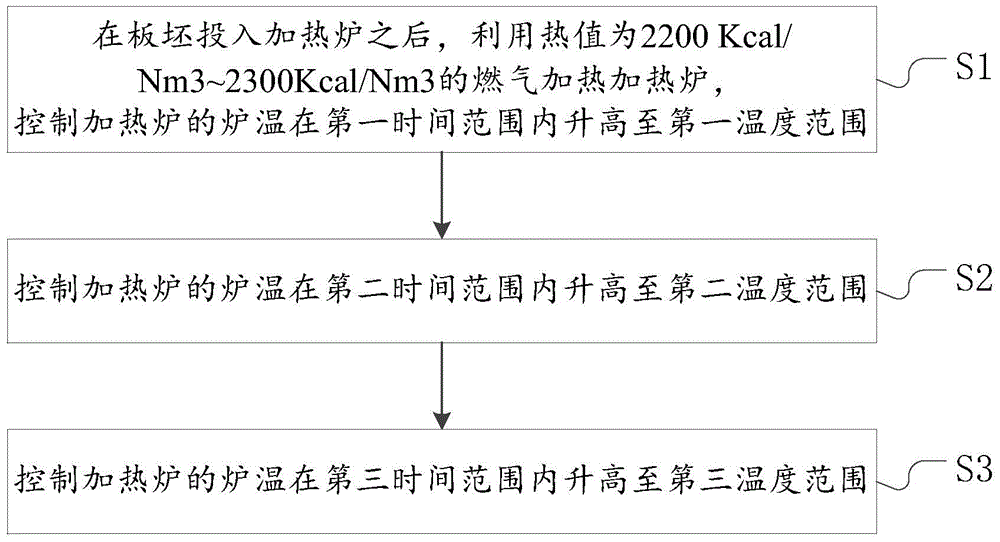

Method used

Image

Examples

example 1

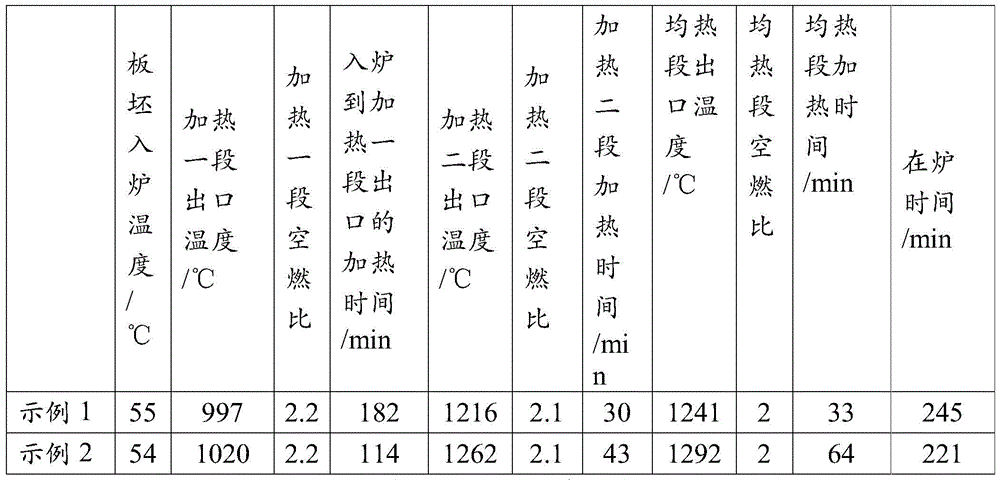

[0032]It is heated by gas with a calorific value of 2100kcal / Nm3. The slab enters the heating furnace at 55°C and is heated to 997°C after 182 minutes. In the second stage of heating, the air-fuel ratio is 2.1, and the temperature is raised to 1216°C in 30 minutes at a heating rate of 7.3°C / min; finally enters the soaking section, and the air-fuel ratio is 2.0. After heating for 33 minutes, the steel is tapped at 1241°C. After the slab comes out of the furnace, it undergoes 4 passes of descaling in the rough rolling, and the steel plate with excellent surface quality is obtained after finishing rolling.

example 2

[0034] Heating gas with a calorific value of 2100kcal / Nm3, the slab enters the heating furnace at 54°C, and heats to 1020°C after 114 minutes; then enters the second heating section, with an air-fuel ratio of 2.1, and heats up to 1020°C at a heating rate of 5.7°C / min after 43 minutes 1262°C; finally enter the soaking section with an air-fuel ratio of 2.0 and heat for 64 minutes. During this period, the steel is kept in the soaking section for about 34 minutes. The air excess coefficient is 0.9 during the soaking section. After the slab comes out of the furnace, it undergoes 4 passes of descaling in the rough rolling, and the steel plate with excellent surface quality is obtained after finishing rolling.

[0035] Through one or more embodiments of the present invention, the present invention has the following beneficial effects or advantages:

[0036] The invention provides a copper-containing low-alloy steel heating method. After the slab is put into the furnace, it is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com