Efficient energy-saving vacuum hot-pressing crystal pulling method of high quality semiconductor refrigeration member

A vacuum hot pressing, high-efficiency and energy-saving technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of poor product quality stability, low effective utilization, waste of energy, etc. Improve utilization and save power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Break the raw material into more than 300 meshes. The raw material used is the same as the zone melting method and other methods, that is, bismuth tritelluride, or a small amount of auxiliary raw material is also added. Those skilled in the art should know that the present invention is compatible with the raw material The composition is irrelevant, that is, as long as it is the raw material of semiconductor grains, it is suitable;

[0019] b. Put the material in the above a above into a hydrogen reduction furnace to evacuate and inject hydrogen to heat for reduction;

[0020] Reduction with hydrogen gas removes a small amount of oxidized substances inside, which can better ensure product quality.

[0021] The above two steps a and b are the same in the following embodiments, and the steps will be described in detail.

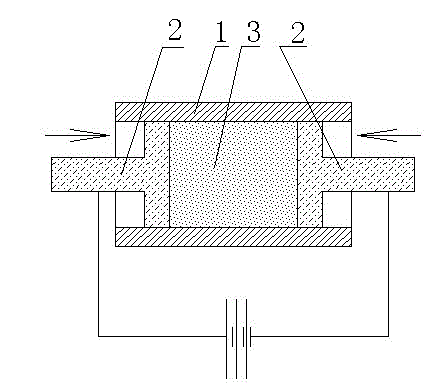

[0022] c. Put the material in the above b into a vacuum hot pressing mold to carry out current hot pressing, such as figure 1 As shown, the mold inc...

Embodiment 2

[0025] The two steps of a and b are the same as above;

[0026] c. Put the material in the above b into a vacuum hot-pressing mold for current hot-pressing. The mold includes a mold cylinder and a pressure piece, the structure is the same as above, the initial pressure is not less than 1.2 tons / square centimeter, and the current is 7A / square cm, the cross-sectional area of the mold cylinder is 4 square centimeters, the current passing between the two pressure parts is 28A, when the temperature is energized to 310°C, the pressure is adjusted to 16 tons / square centimeter and kept for 65 minutes, when the temperature reaches 460°C , adjust the pressure again to reach 22 tons / square centimeter, keep it for 20 minutes, turn off the heating power supply, and allow it to cool down naturally to obtain the crystal pulling rod.

[0027] In this way, the quality of the refrigerating parts made from the produced ingots is better, and not only can be used as refrigerating parts, but also...

Embodiment 3

[0029] The two steps of a and b are the same as above;

[0030] c. Put the material in the above b into a vacuum hot-pressing mold for current hot-pressing. The mold includes a mold cylinder and a pressure piece with the same structure as above; the initial pressure is 0.85 tons / square centimeter, and the current is 4A / square centimeter , the cross-sectional area of the mold cylinder is 4 square centimeters, and the current passing between the two pressure parts is 16A. When the power is turned on and the temperature is raised to 280°C, the pressure is adjusted to 8 tons / square centimeter and kept for 1 hour. When the temperature reaches 420°C , adjust the pressure again to reach 17 tons / square centimeter, keep it for 70 minutes, turn off the heating power supply, and allow it to cool down naturally to obtain the crystal pulling rod.

[0031] Like this, the refrigerating piece product that the crystal rod that produces is further made is poorer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com