Small multifunctional rock drill

A multi-functional, drilling rig technology, applied in the field of drilling rig machinery, can solve the problems of high purchase cost, increased construction cost, and large machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

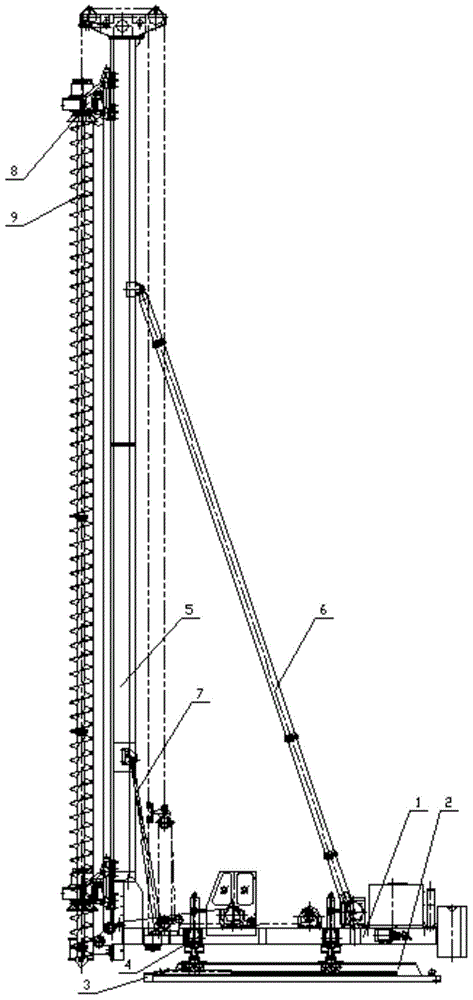

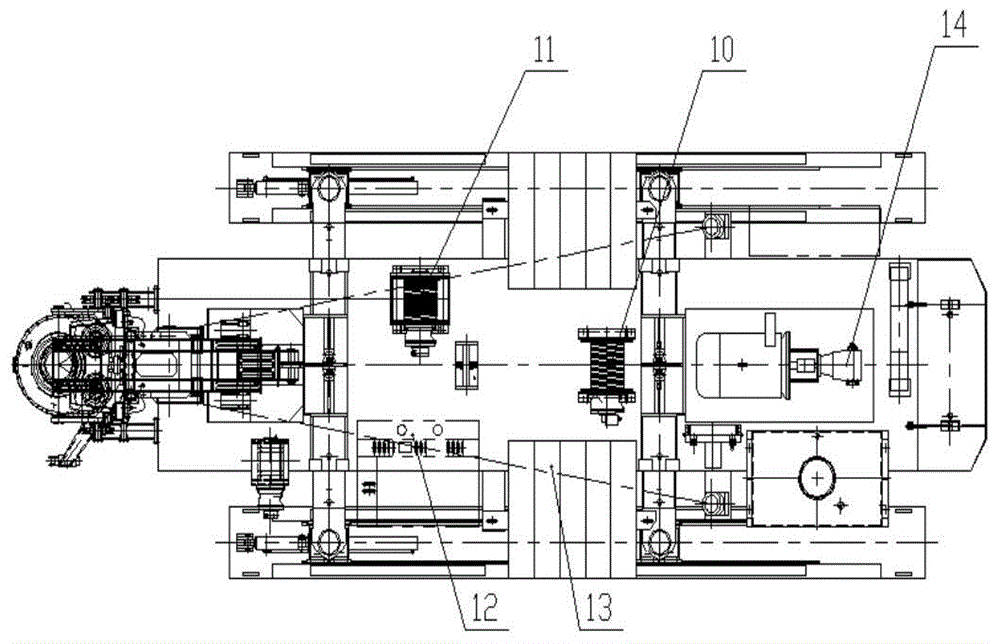

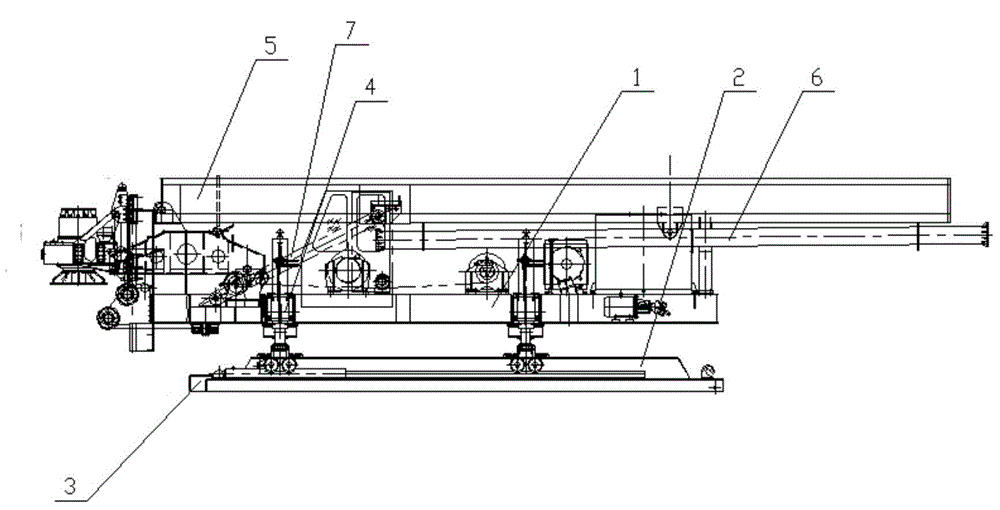

[0022] Such as Figure 1~4 As shown, a small multifunctional rock drilling rig provided by the present invention includes a fuselage platform 1, a vertical movement mechanism 2, a lateral movement mechanism 3, a lifting mechanism 4, a mast mechanism 5, a brace 6, a mast lifting cylinder 7, a power The head 8, the drill pipe 9, and the fuselage platform 1 are connected with the vertical movement mechanism 2 and the lateral movement mechanism 3 through the lifting mechanism 4. The vertical movement mechanism 2, the transverse movement mechanism 3 and the lifting mechanism 4 form the chassis of the drilling rig. The three mechanisms cooperate to realize the front, rear, left, and right walking and turning of the drilling rig, and the chassis adopts a step-over-step walking chassis with good stability. One end of the brace 6 is connected to the fuselage platform 1 , and the other end is connected to the mast mechanism 5 . The brace 6 is used to support the mast mechanism 5 and to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com