Novel fir board

A fir and plank technology, which is applied in the field of new fir planks, can solve the problems of rough surface, poor appearance quality, and monotonous color of fir finished timber, and achieve the effects of improved physical and mechanical properties, simple formula, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

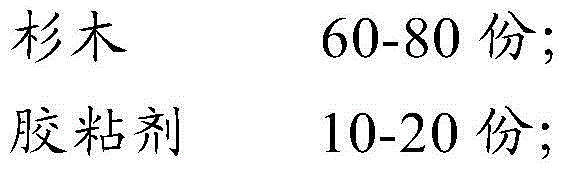

[0015] This embodiment discloses a novel Chinese fir board, comprising the following components by weight ratio:

[0016]

[0017] The moisture content of described Chinese fir is 10%. The adhesive is urea-formaldehyde resin with a viscosity of 0.12 Pa.s (20° C.). The curing agent is NH 4 Cl. The waterproofing agent is molten paraffin. The novel Chinese fir board of the present invention also includes putty, usually shellac putty. The filler is industrial flour.

Embodiment 2

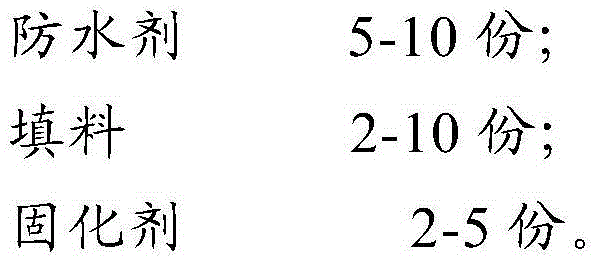

[0019] This embodiment discloses a novel Chinese fir board, comprising the following components by weight ratio:

[0020]

[0021]

[0022] The moisture content of the Chinese fir is 8-10%. The adhesive is urea-formaldehyde resin with a viscosity of 0.12 Pa.s (20° C.). The curing agent is NH 4 Cl. The waterproofing agent is molten paraffin.

[0023] The novel Chinese fir board of the present invention also includes putty, usually shellac putty. The filler is industrial flour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com