Fluidized bed boiler air input capacity control method based on model online identification

A fluidized bed boiler and air volume control technology, applied in fluidized bed combustion equipment, combustion methods, combustion types, etc., can solve the problems of the combustion rate not reaching the highest value, wasting energy, and operator lag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

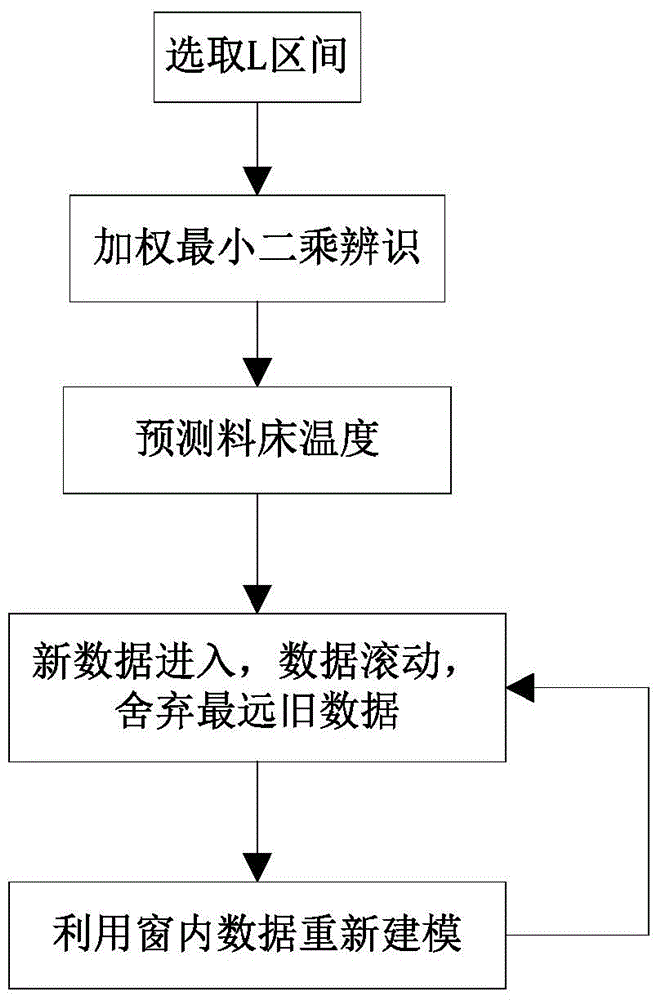

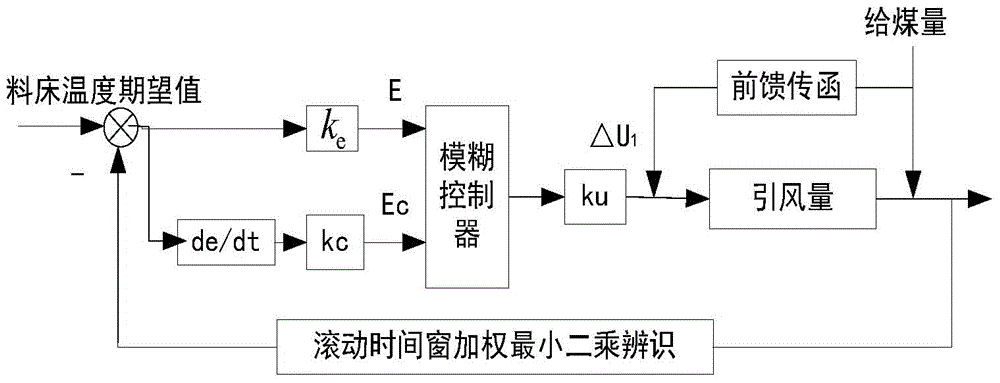

[0105] Step 1. Select 120 groups of induced air volumes as the input of the online identification model. When the 20th induced air volume is read, a material bed temperature can be identified online. After that, it can be identified online according to the above steps every other sampling period. A material bed temperature. Among them: the weight of the first data is 0.1, and the weights of the next 19 data are h m =0.1+m*(1-0.1) / 20, m=1,2...20. When using the weighted least square method based on the rolling time window to identify the material bed temperature online, the error of the online identification material bed temperature within 120 sampling periods is as follows Figure 5 shown.

[0106] Step 2, compare the material bed temperature value identified online with 900 degrees Celsius (the expected material bed temperature value), the difference in material bed temperature is quantified with a quantization factor of 0.9, and the change rate of the error is quantified w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com