Cooling system and method of airborne heating elements based on evaporative refrigeration

A heating element, evaporative refrigeration technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the cooling technology cannot meet the cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

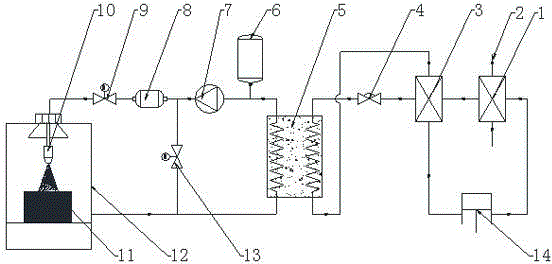

[0011] like figure 1 As shown, an airborne high heat flow heating element cooling system combined with electric power according to the present invention includes a condenser 1, a ram air port 2, a regenerator 3, an expansion valve 4, a cold storage device 5, a buffer tank 6, and a circulation Pump 7, filter 8, flow regulating valve 9, cooling nozzle 10, heating element 11, spray chamber 12, bypass valve 13, compressor 14.

[0012] The specific implementation process of the spray cooling process is as follows: the low-temperature brine is pressurized by the circulating pump 7 and then sent to the cooling nozzle 10, atomized into micron-sized droplets, and forced to spray to the surface of the heating element 11 to take away a large amount of heat. In non-boiling spray cooling, the heat transfer mechanism is mainly forced convection and liquid film evaporation, while in phase change spray cooling, nucleate boiling and secondary nucleation play a more obvious role. Spray cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com