Align the imaging device

An imaging device and imaging technology, applied in the semiconductor field, can solve the problems of low energy utilization rate and uneconomical, etc., and achieve the effect of simple and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

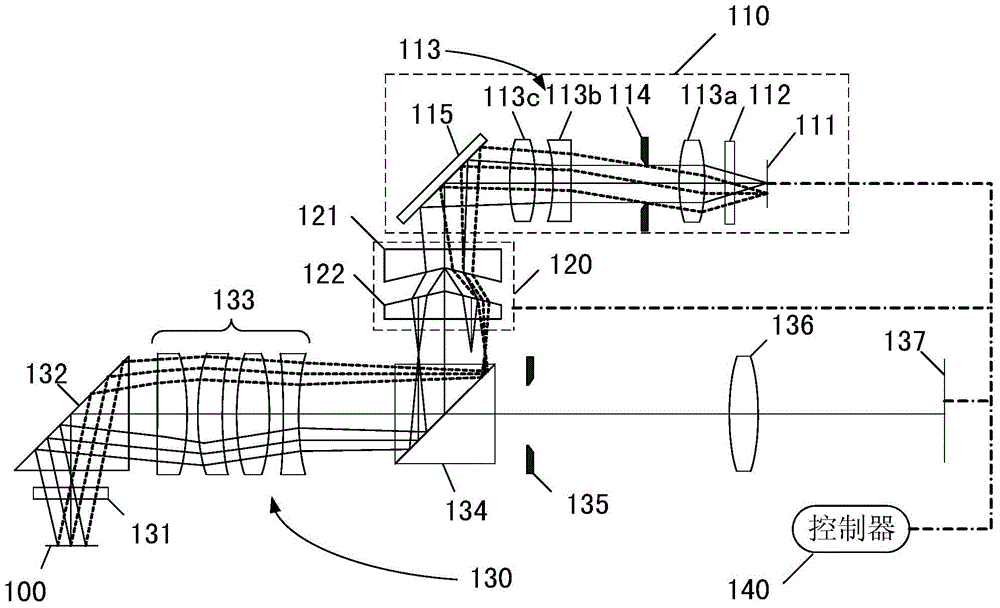

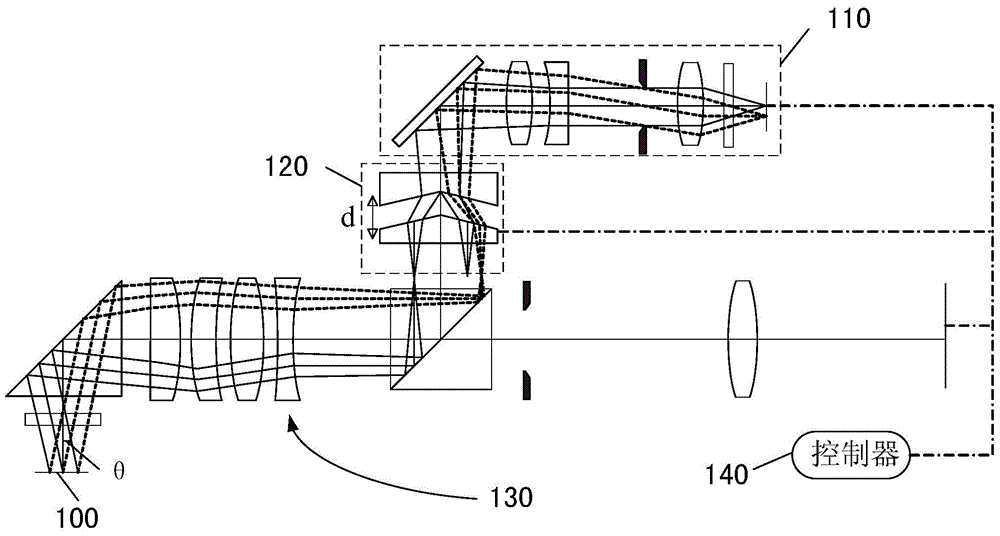

[0030] Such as figure 1 As shown, in this embodiment, the alignment forming device is composed of two parts: an alignment imaging lens and a controller 140, wherein the alignment imaging lens is used to image the alignment marks on the surface of the silicon wafer 100, and the imaging assembly 130 It consists of two parts, coaxial lighting components.

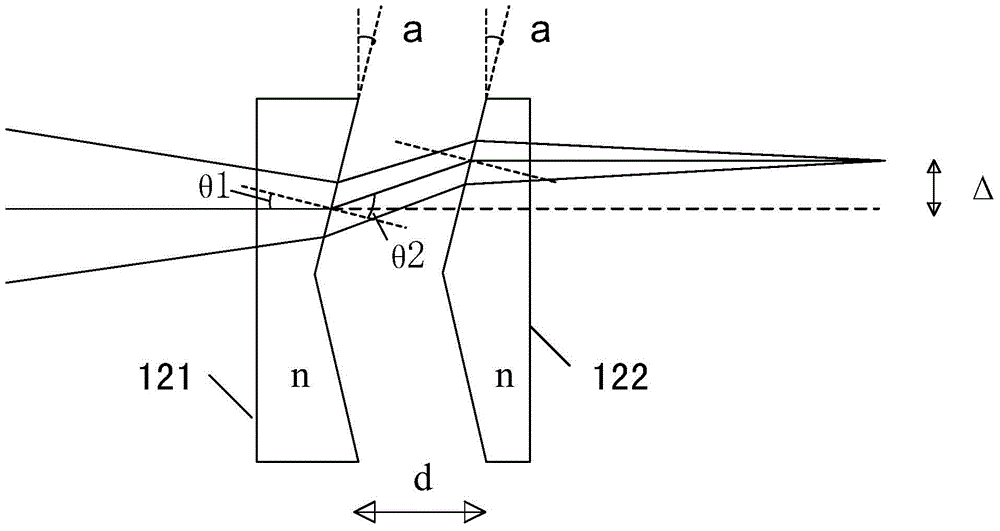

[0031] The coaxial lighting assembly includes a lighting front group 110 and a corner cube prism group 120 , and the main function of the coaxial lighting assembly is to provide different lighting modes for aligning the imaging lens to enhance the image. Wherein, the illumination front group 110 is used to provide illumination beams, which sequentially include: a light source 111, a filter assembly 112, an illumination lens group 113, an illumination field diaphragm 114, and a reflection unit 115 along the direction of light propagation; further, The illumination lens group 113 includes: first, second and third illumination le...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the present embodiment transforms the corner cube group into a Fresnel lens or a binary optical element 120' equivalently, and its equivalent schematic diagram is as follows Figure 8a and Figure 8b shown.

[0052] The switching mode of the different illumination modes of the Fresnel lens or the binary optical element 120' is the same as that of the corner cube prism group, and the partial schematic diagram of the switching of the illumination modes is as follows Figures 9a-9c As shown, the binary optical element adopts a binary optical corner cube. Since the other parts and work flow of the alignment forming device in this embodiment are the same as those in Embodiment 1, details are not repeated here.

[0053] In summary, the alignment imaging device of the present invention includes: an imaging component, a coaxial lighting component, and a controller; wherein, the coaxial lighting component includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com