Electric motor having an electronic module, preferably an electrically-commutated motor

An electric motor, electronic module technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as large structure space, and achieve the effect of small structure space, simplified installation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

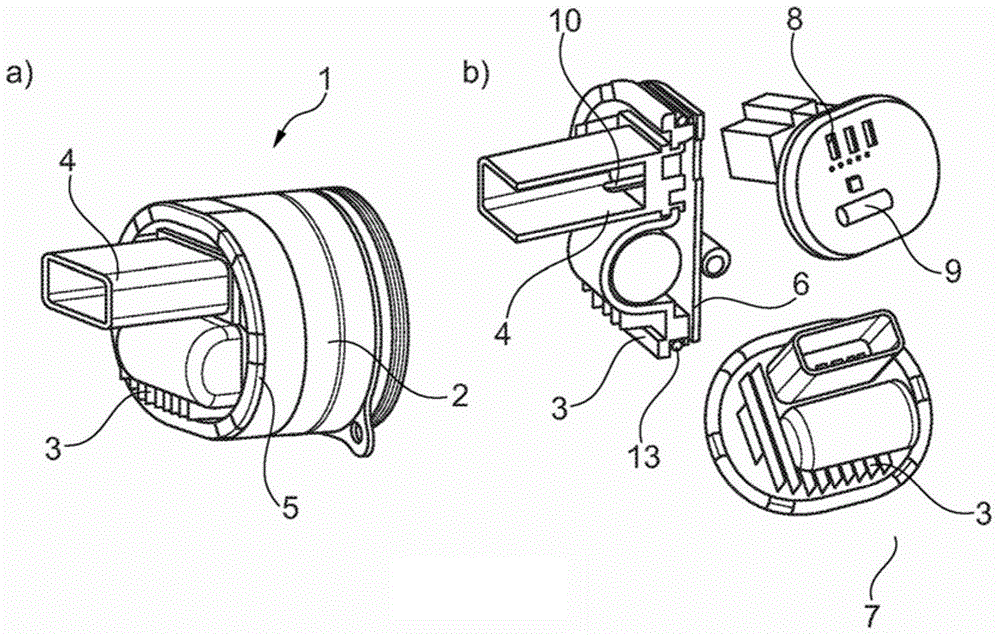

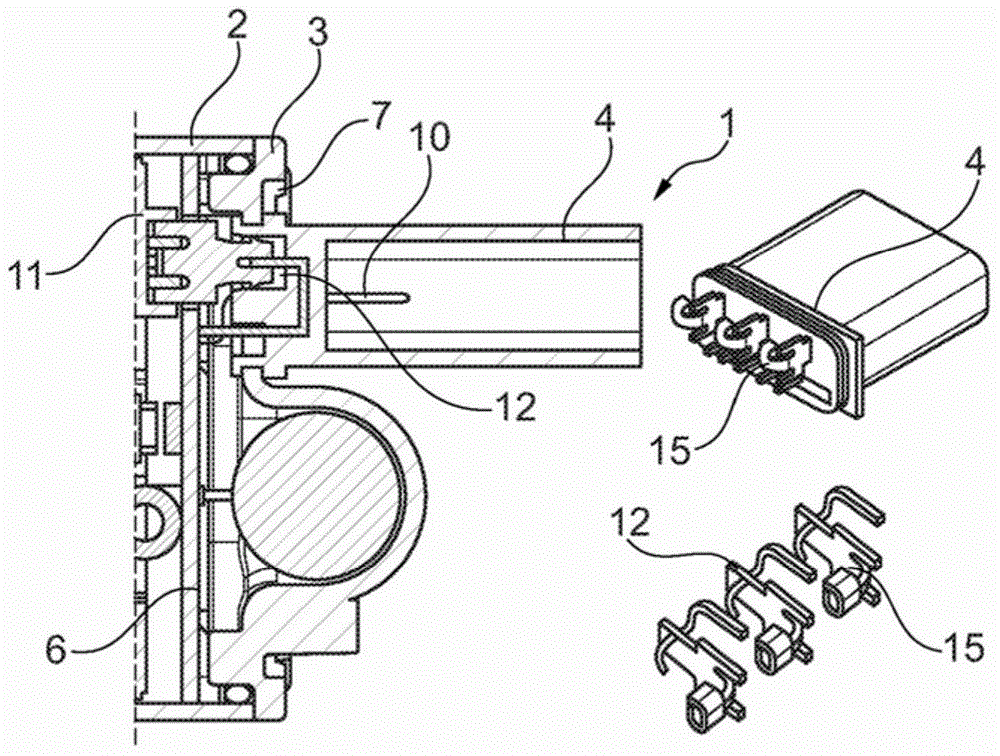

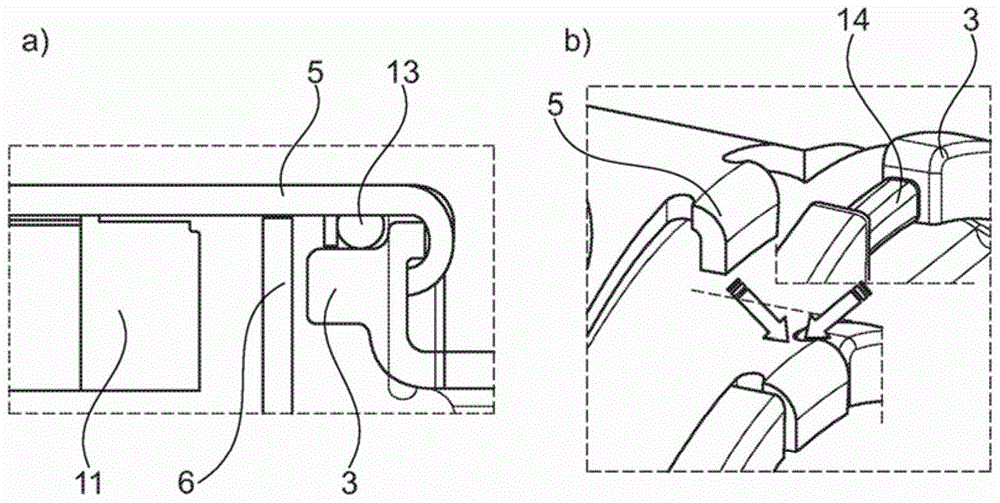

[0031] exist figure 1 An electrically commutated motor, for example for controlling a clutch actuator in a motor vehicle, is shown in , together with control electronics 1 . These are brushless DC motors, which are also referred to as BLDC motors (Brushless DC Motors), in which the otherwise usual mechanical commutator with brushes for commutation is replaced by an electronic circuit. The electric motor 1 according to figure 1 a consists of a deep-drawn housing 2 which is sealed by a heat sink 3 made of aluminum die-cast. The plug-in unit 4 made of plastic is a component of the heat sink 3 and is injected or glued into it, for example. The cylindrical-like housing 2 of the electric motor 1 has, on its radial circumference facing the heat sink 3 , a plurality of bent webs 5 which are formed in one piece from the housing 2 and face the heat sink 3 . Folding in the direction in order to thereby achieve an axial fixation of the electronics module 7 formed by the electronics uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com