Water-assisted injection molding and gas-assisted molding common nozzle

A gas-assisted molding and nozzle technology, which is applied in the field of water-assisted molding and gas-assisted molding of plastic molding molds, can solve problems such as air leakage, molten material easily entering the air needle gap, and poor sealing of the air needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

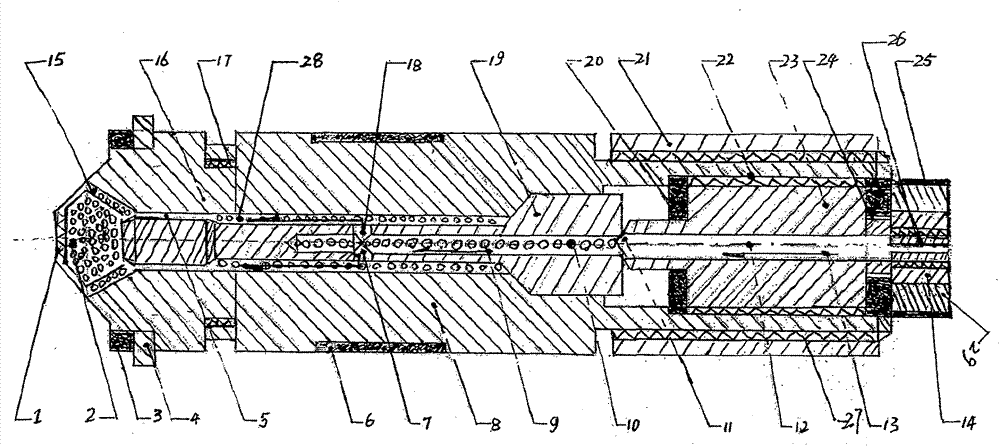

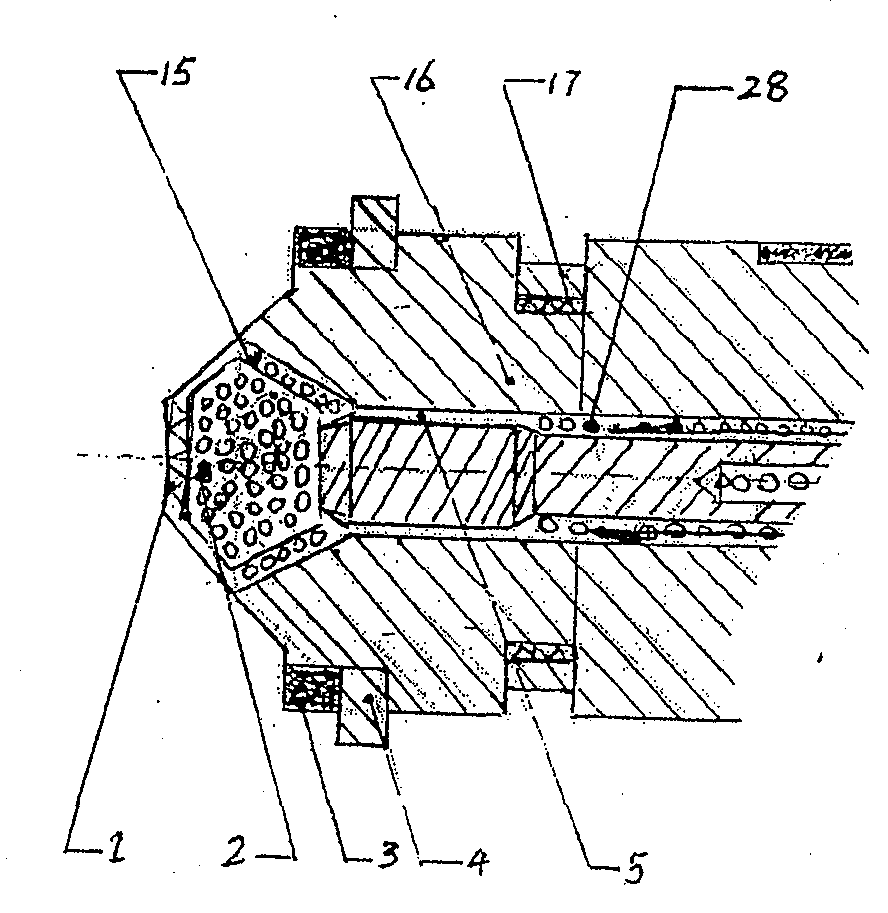

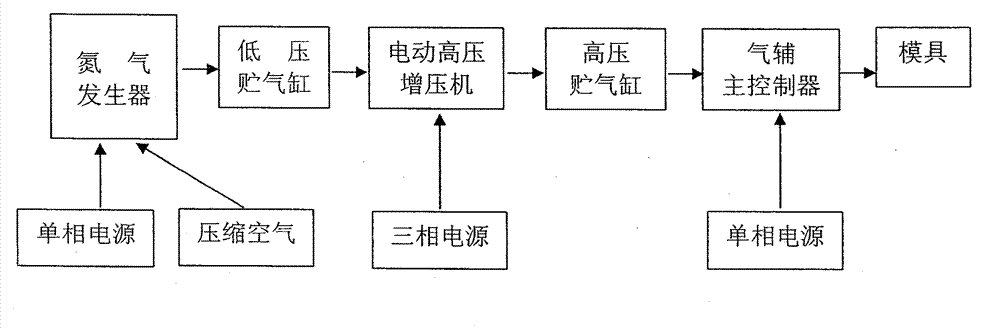

[0024] As shown in the figure, it is a common nozzle for water-assisted molding and gas-assisted molding. The characteristics of this nozzle are: 1. It can be used for water-assisted molding and gas-assisted molding. 2. Its pressure can be adjusted. When a larger pressure or a lower pressure is required, the second copper sleeve (21) can be twisted to drive the nozzle body (8) to rotate. The inner wall of the second copper sleeve (21) is set The thread and the external thread on the nozzle body (8) form a toothed engagement [engagement shape such as figure 1Shown at (27)], when the nozzle body (8) rotates, the second-stage mandrel (19) fastened in the inner hole of the nozzle body (8) rotates with the rotation, because the second-stage The hole on the core rod (19) is flexibly connected with the first-level core rod (23), and the water outlet hole on the first-level core rod (23) is designed as an eccentric hole [as figure 1 (11)], when a higher pressure is required, it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com