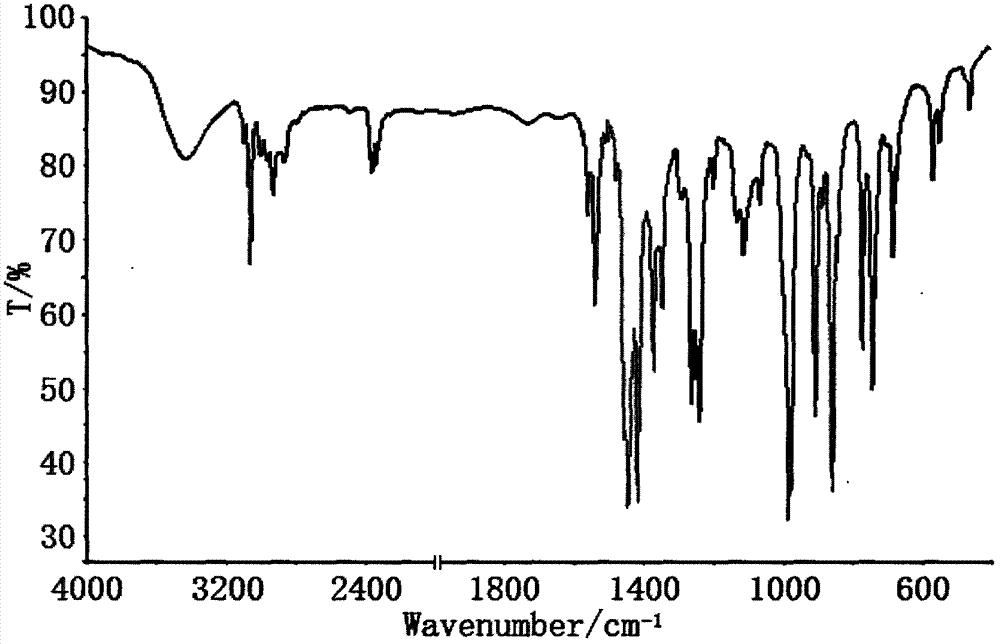

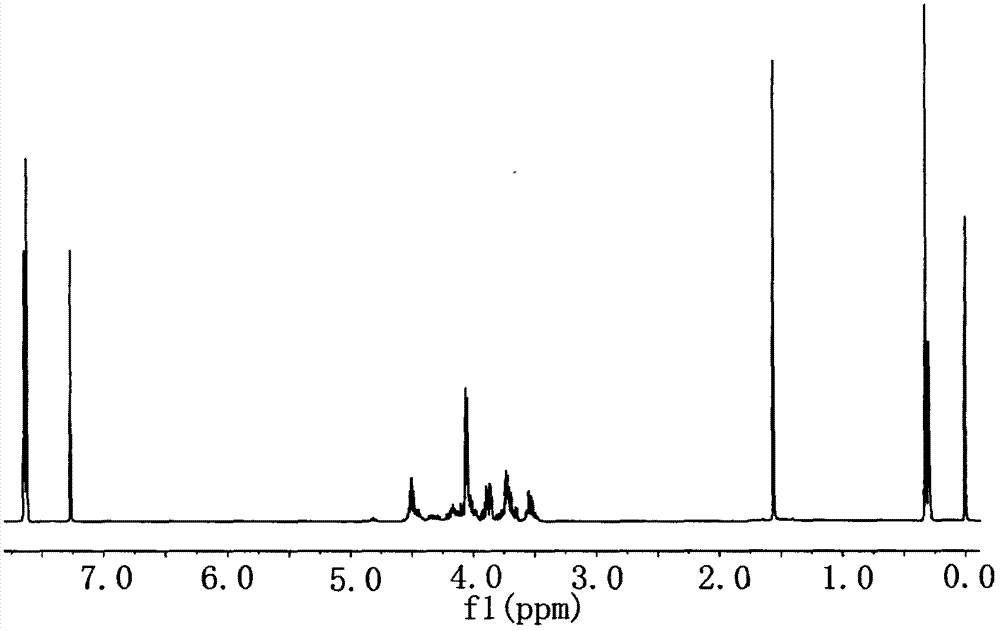

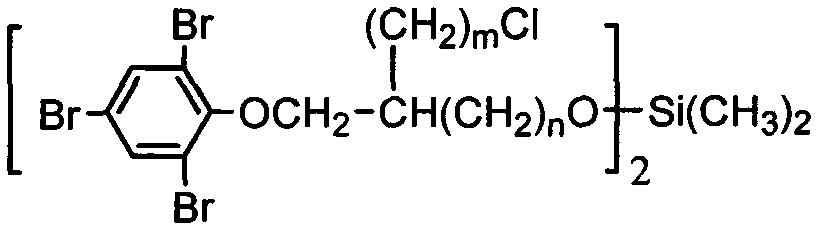

Bis(2,4,6-tribromophenoxychloropropyl) dimethyl silicate compound and preparation method thereof

A technology of tribromophenoxychloropropyl and dimethyl silicate, applied in the field of dimethyl silicate bis(2,4,6-tribromophenoxychloropropyl) ester compound and its preparation , can solve problems such as difficulty in finding substitutes, and achieve the effect of large molecular weight, low volatility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 In a 250ml four-necked flask equipped with a stirrer, a thermometer and a condenser tube, replace the air in the bottle with nitrogen, and add 38.75g (0.1mol) of 2,4,6-tribromophenylepoxypropyl Ether and 100ml of benzene, add 6.45g (0.05mol) dimethyl dichlorosilane dropwise, control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 70°C after dropping, keep the reaction for 10h, and distill off the solvent and A small amount of low-boilers gave bis(2,4,6-tribromophenoxychloropropyl) dimethyl silicate with a yield of 95.3%.

Embodiment 2

[0028] Example 2 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a condenser tube, replace the air in the bottle with nitrogen, and add 38.75g (0.1mol) of 2,4,6-tribromophenylepoxypropyl Ether and 70ml xylene, add 6.45g (0.05mol) dimethyldichlorosilane dropwise, control the reaction temperature not higher than 40°C with the dropping speed, raise the temperature to 100°C 1h after the drop, keep the reaction for 6h, and distill under reduced pressure to remove Solvent and a small amount of low-boiling-point substances were used to obtain bis(2,4,6-tribromophenoxychloropropyl) dimethyl silicate with a yield of 97.8%.

Embodiment 3

[0029] Example 3 In a 250ml four-necked flask equipped with a stirrer, a thermometer and a condenser, replace the air in the bottle with nitrogen, and add 38.75g (0.1mol) of 2,4,6-tribromophenylepoxypropyl Ether and 120ml xylene, add 6.45g (0.05mol) dimethyldichlorosilane dropwise, control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 95°C 1h after the drop, keep the reaction for 7h, and distill under reduced pressure to remove Solvent and a small amount of low-boiling-point substances were used to obtain bis(2,4,6-tribromophenoxychloropropyl) dimethyl silicate with a yield of 97.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com