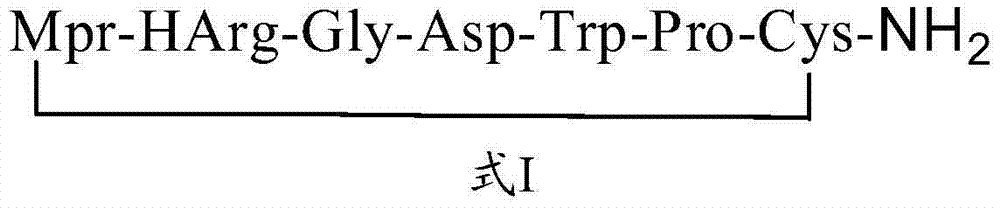

Eptifibatide preparation method

A technology of eptifibatide and fmoc-cys, which is applied in the field of polypeptide drug preparation, can solve the problems of affecting drug safety, many synthesis steps, complicated processes, etc., and achieves the effects of avoiding difficulty in recovery, ensuring oxidation rate, and reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing eptifibatide, which can be achieved by those skilled in the art by referring to the content of this article and appropriately improving the process parameters. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0032] The reagents used in the present invention are all commercially available and can be purchased in the market.

[0033] Wherein, the Chinese and English names of reagents used in ...

Embodiment 1~3

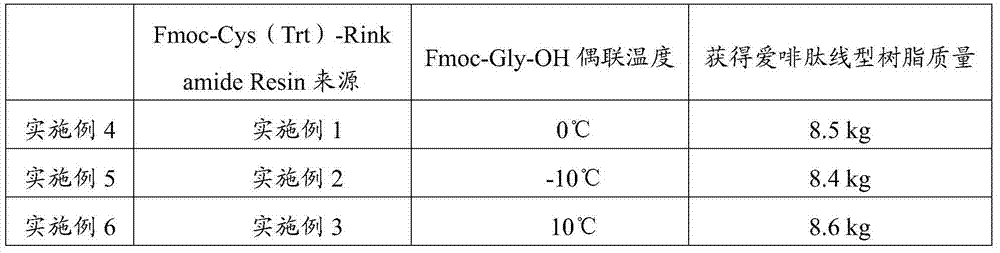

[0038] Example 1-3 Synthesis of Fmoc-Cys(Trt)-Rink amide Resin

[0039]Take 5kg of Rink amide Resin resin (sub=0.5mmol / g, synthesis scale: 2.5mol), add it to the reaction column, wash it twice with 15L DMF, swell with 15L DMF for more than 30 minutes, and use 15L 20% piperidine / DMF solution (DBLK) Remove Fmoc twice, 10 minutes each time, wash six times with 15LDMF after removing Fmoc protection. Weigh Fmoc-Cys (Trt)-OH (4.4Kg, 7.5mol) and HOBt (1.2kg, 9mol) and dissolve it with 6.5L of DCM and DMF mixed solution (V / V=1:1), and cool the mixed solution to Add the activator DIC (1.5L, 9.75mol) after 0°C, activate for 5 minutes and then add to the reaction, react at 0±10°C for 2 hours. The reaction was terminated after the ninhydrin test was negative. Washed 6 times with 15L DMF to obtain Fmoc-Cys(Trt)-Rink amide Resin.

Embodiment 1~4

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com