Extraction technology of high-stability odorless purple corn pigment

An extraction process and high stability technology, which is applied in the field of high stability and odorless purple corn pigment extraction process, can solve the problems of low extraction rate, poor quality, and instability of products, and achieve simple production process, high yield, and pigment extraction rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

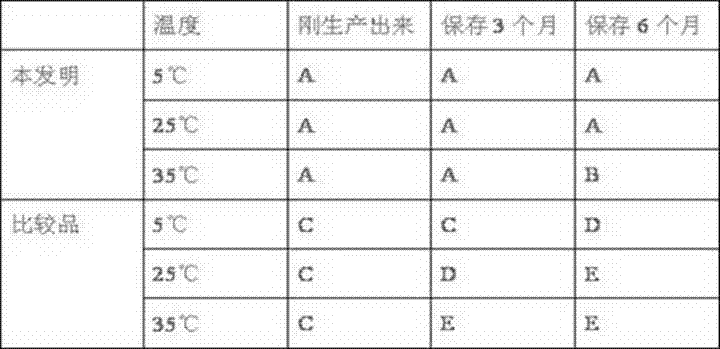

Image

Examples

Embodiment 1

[0022] (1) Solvent extraction: Soak in citric acid aqueous solution with pH=2.5, set the extraction temperature to 75°C, repeat the extraction three times, each extraction time is 1.5h for corn husks and 2h for corn cobs;

[0023] (2) Ultrasonic treatment: Then place it in an ultrasonic instrument at 45°C, control the conditions at 0°C, ultrasonic power at 100W, ultrasonic frequency at 45KHZ, and ultrasonically treat for 30 minutes;

[0024] (3) Enzyme treatment: add 100u / g medium-temperature amylase, adjust PH=2.5, control temperature at 45°C, and enzymatically treat for 90 minutes;

[0025] (4) Filtration and extraction: filter the above extract under reduced pressure, and extract the filtrate by centrifuging at 2500r / min for 8min;

[0026] (5) Adsorption: put the filtrate on the SP-207 macroporous resin adsorption column, and perform adsorption at a flow rate of 20M3 / h;

[0027] (6) Membrane treatment: use AHP ultrafiltration membrane at 3kg / cm 2 , under the condition of ...

Embodiment 2

[0031] (1) Solvent extraction: Soak in citric acid aqueous solution with pH = 3.0, set the extraction temperature to 80°C, and repeat the extraction three times, each extraction time is 2 hours for corn husks and 3 hours for corn cobs;

[0032] (2) Ultrasonic treatment: Then place it in an ultrasonic instrument at 55°C, control the conditions at 5°C, ultrasonic power 100W, ultrasonic frequency 50KHZ, and ultrasonic treatment for 50 minutes;

[0033] (3) Enzyme treatment: Add 120u / g medium-temperature amylase, adjust PH=3.0, control temperature at 50°C, and enzymatically treat for 120min;

[0034] (4) Filtration and extraction: filter the above extract under reduced pressure, and extract the filtrate by centrifuging at 3500r / min for 12min;

[0035] (5) Adsorption: put the filtrate on the SP-207 macroporous resin adsorption column, and perform adsorption at a flow rate of 60M3 / h;

[0036] (6) Membrane treatment: use AHP ultrafiltration membrane at 3.5kg / cm 2 , under the condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com