Coke oven coke barriering and dust removal method

A technology of coke oven and dust removal system, which is applied in coke oven, furnace prevention/removal of fouling, petroleum industry, etc., can solve the problems of high operating cost and high one-time investment, achieve low operating cost, prevent environmental pollution, and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

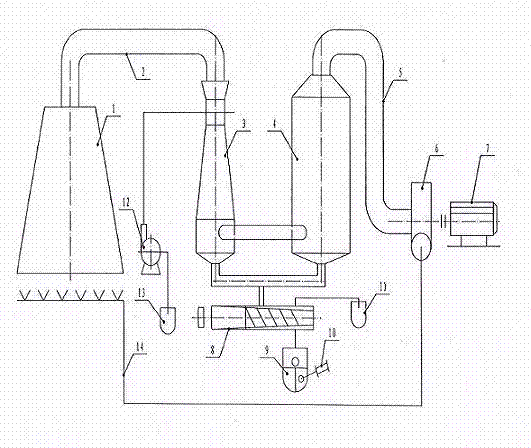

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

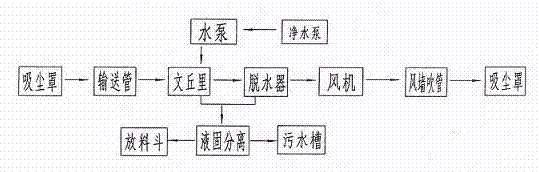

[0014] like figure 1 , figure 2 As shown, the method for coke arresting and dedusting of the coke oven is characterized in that: the method for dedusting the coke of the coke oven comprises the following steps:

[0015] Step 1: Start the fan 6 of the dust removal system before unloading the coke, so that the mouth of the dust collection cover 1 generates a negative pressure suction state.

[0016] Step 2: When unloading the coke, the dust above the coke barrier and the coke quenching car is sucked up by the red coke collapsed and raised by the dust hood 1 and transported to the Venturi 3 for washing. After washing, it enters the dehydration tower 4 for dehydration.

[0017] Step 3: The dehydrated gas is sent to the lower opening of the dust collection hood 1 by the blower fan 6 through the pipeline, and serves as an air curtain wall.

[0018] Step 4: The sewage co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com