Heterogeneous high damping magnesium alloy

A high damping, magnesium alloy technology, applied in the field of magnesium alloy production, can solve the same problems such as the reduction of damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The preparation method of alloy of the present invention comprises the steps:

[0011] 1. The raw material is industrial magnesium ingot (purity is 99.95wt%), melted in SG2-5-12 well-type resistance furnace, and SF6 protective gas is used in the melting process;

[0012] 2. After melting the magnesium ingot at 750°C, add a certain proportion of tin ingot (99.98wt% purity) and other alloying elements, and keep it in the furnace at 680-730°C for 20-40min;

[0013] 3. After the end, let it cool down and cast it in a protective atmosphere;

[0014] 4. The as-cast alloy is solidified at 460-500°C for 24 hours, then water-cooled, and then aged at 200-240°C for 10-24 hours;

[0015] 5. Damping performance test

[0016] The damping performance was characterized by the JN-1 Gerner pendulum tester. For the samples of each alloy composition in the as-cast state, T4 state, and T6 state, the circular cross-section alloy wire with a diameter of 1.5 mm and a length greater than 5 m...

Embodiment 1

[0019] The purity of magnesium and tin is respectively selected as Mg99.95wt%, Sn99.98wt%. First, put the pure magnesium ingot into the melting furnace, after it is completely melted, raise the temperature of the melt to 750°C, then add the preheated tin ingot into the melt, stir evenly, let it stand for 15 minutes, and then lower the temperature to 680°C ℃ casting, casting process is always in N 2 Gas and SF 6 under a protective atmosphere. The composition of the castings obtained is shown in Table 1.

[0020] Table 1 1# sample composition (weight percentage)

[0021]

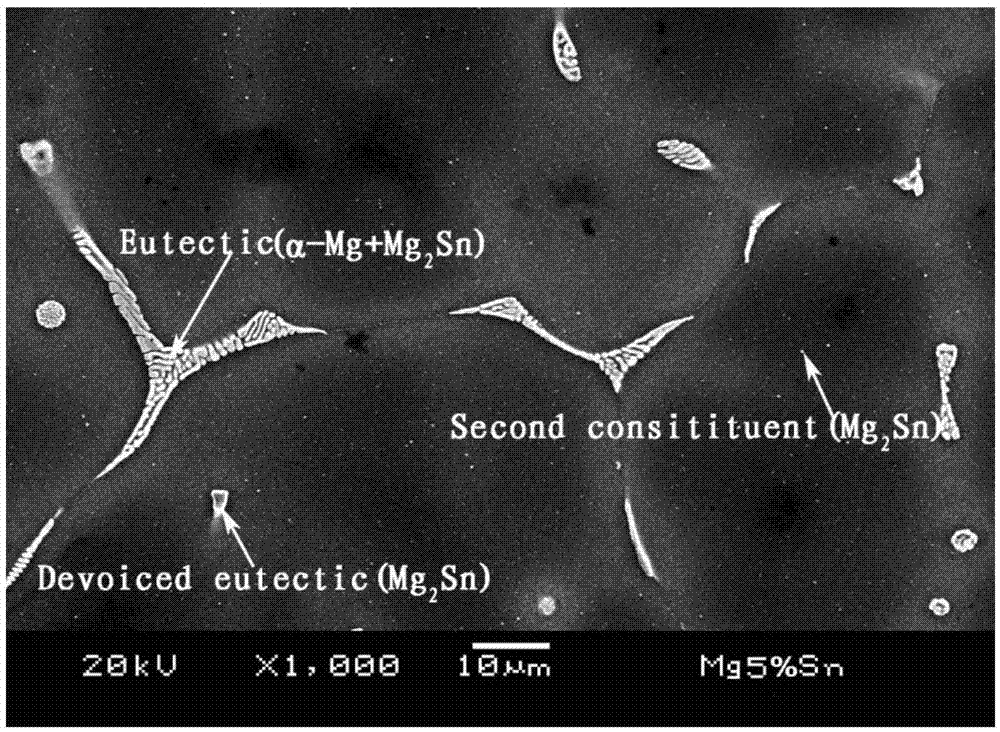

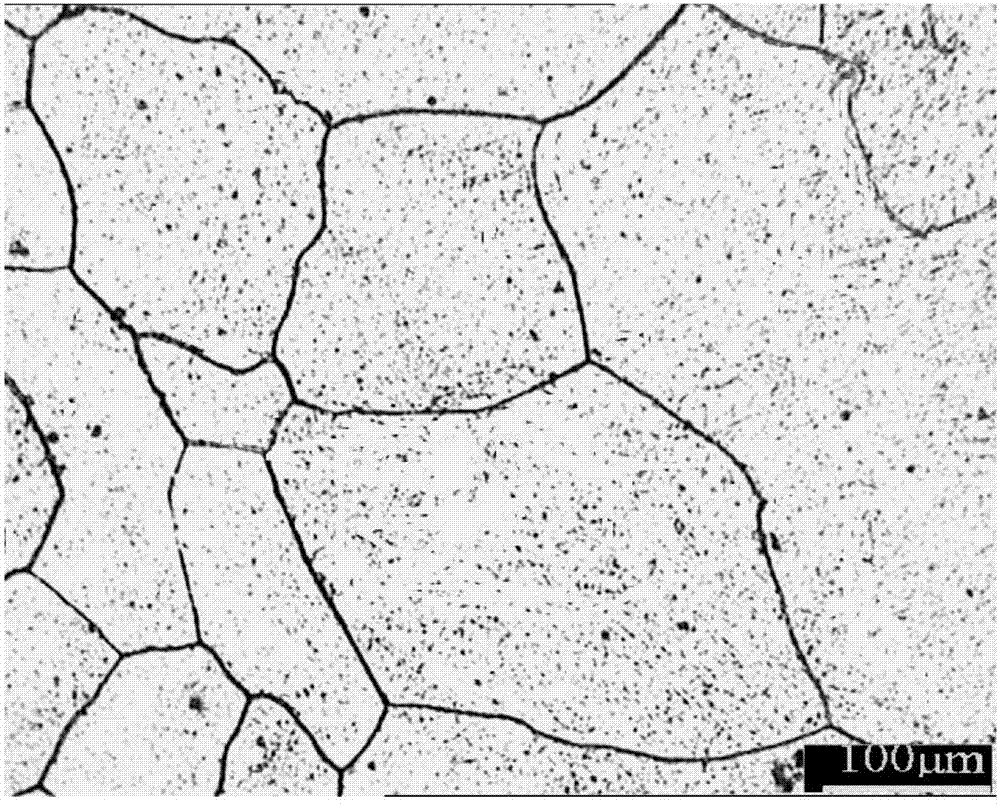

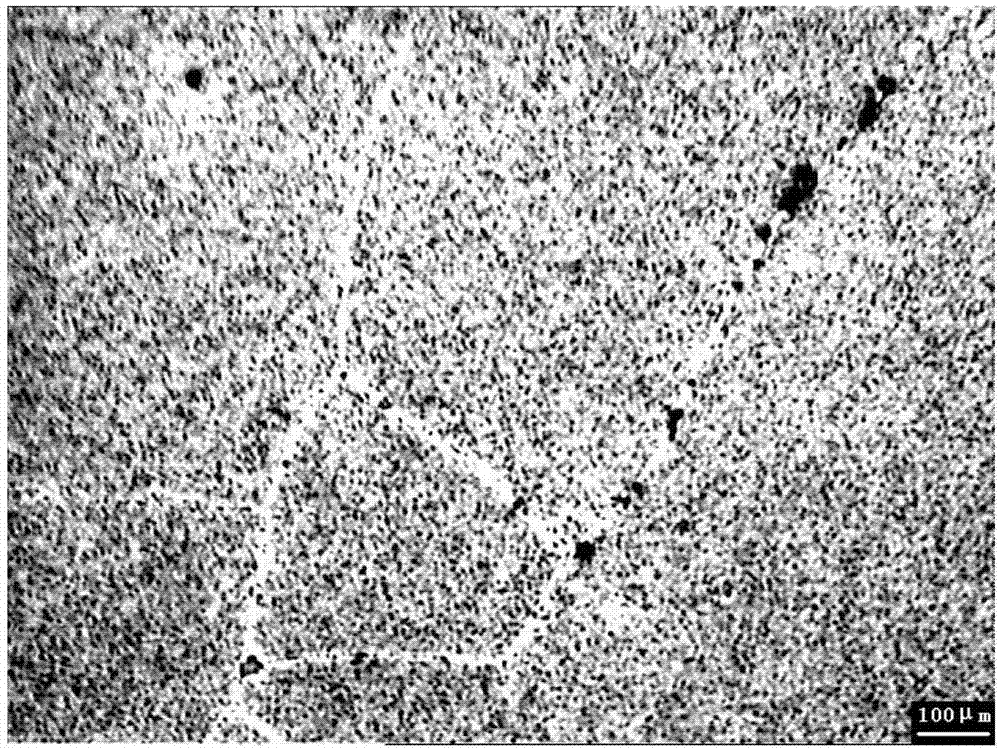

[0022] As-cast microstructure such as figure 1 As shown, lamellar eutectic Mg2Sn can be seen. The as-cast alloy was dissolved in water at 500°C for 24 hours and then water-cooled, the eutectic Mg2Sn phase disappeared as figure 2 As shown, and then aged at 220°C for 12 hours, intermetallic compounds dispersed in the alloy such as image 3 shown. Respectively cut the cast state, T4, T6 state samples...

Embodiment 2

[0024] The purity of magnesium and tin is Mg99.95wt%, Sn99.98wt%, and Zr is Mg-30%Zr master alloy. First put the pure magnesium ingot into the melting furnace, after it is completely melted, raise the temperature of the melt to 750°C, then add the preheated tin ingot and Mg-Zr intermediate alloy into the melt, stir evenly, and let it stand for 15 minutes , and then cooling down to 680°C for casting, the casting process is always under N 2 Gas and SF 6 under a protective atmosphere. The composition of the castings obtained is shown in Table 2.

[0025] Table 2 2# sample composition (weight percentage)

[0026]

[0027] As-cast microstructure such as Figure 5 As shown, lamellar eutectic Mg2Sn can be seen. The as-cast alloy was dissolved in water at 500°C for 24 hours and then water-cooled, the eutectic Mg2Sn phase disappeared as Figure 6 As shown, and then aged at 220°C for 12 hours, dispersed intermetallic compounds were precipitated in the alloy such as Figure 7 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com