Three-jaw snapping supporting single crystal furnace crucible taking-out apparatus

A technology for taking out devices and single crystal furnaces, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of large local force, uneven force on the crucible, and low production efficiency, and achieve uniform force , protection of the crucible, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

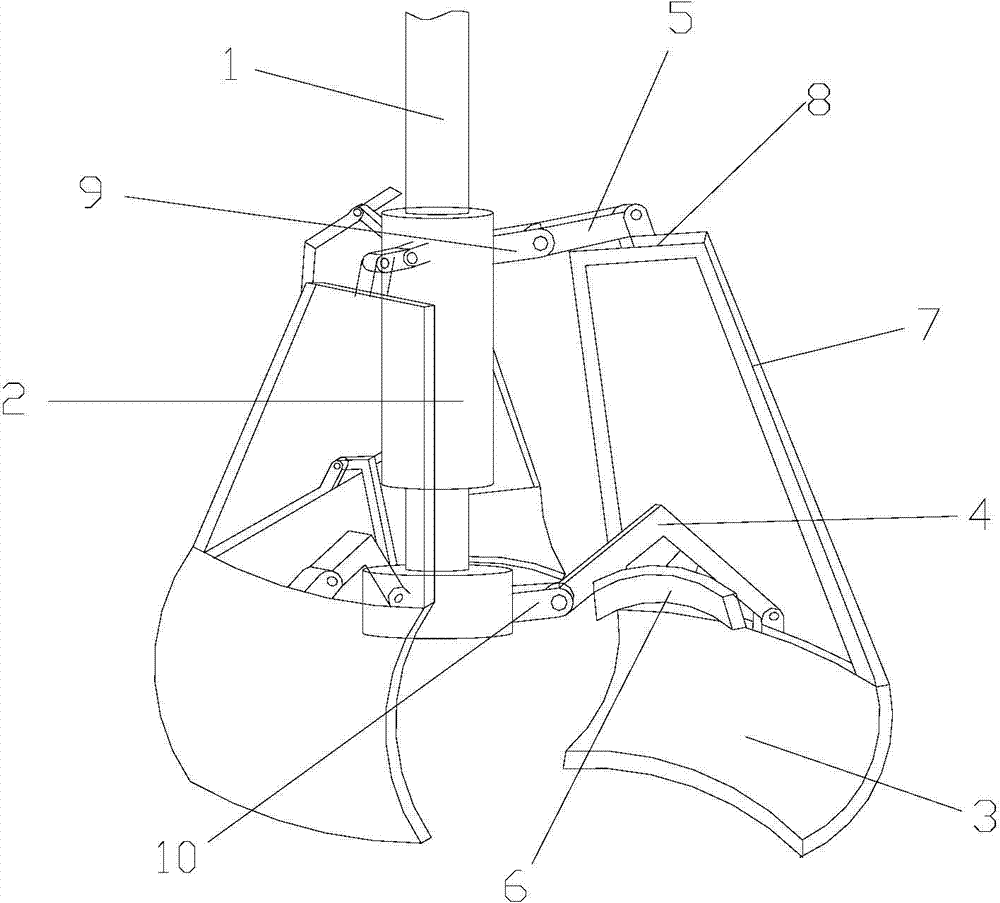

[0013] like figure 1 , a three-jaw card holder single crystal furnace crucible take-out device, comprising a lifting rod 1, a lifting sliding sleeve 2, a supporting plate 3, a support arm 4 and a connecting rod 5, the lifting sliding sleeve 2 is arranged outside the lifting rod 1, and the lifting rod 1 It can slide relative to the lifting sliding sleeve 2, and the supporting plate 3, the support arm 4 and the connecting rod 4 form a card supporting mechanism. A uniformly distributed second hinged projection 10 corresponding to the direction of the first hinged projection 9 of the lifting rod 1, the angle between the first joint projection 9 and the three second hinged projections 10 is 120°, Both sides of the top of the supporting plate 3 forming the card holder mechanism are provided with pull rods 7, and the top of the pull rods 7 is provided with a pull bar cross bar 8, and the connecting rod 5 is hinged with the protrusion arranged in the middle of the upper middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com