Water heater heat exchanger and manufacturing method thereof

A manufacturing method and heat exchanger technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of low efficiency and low strength of aluminum alloy heat exchangers, and achieve cost reduction, pollution-free water quality, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

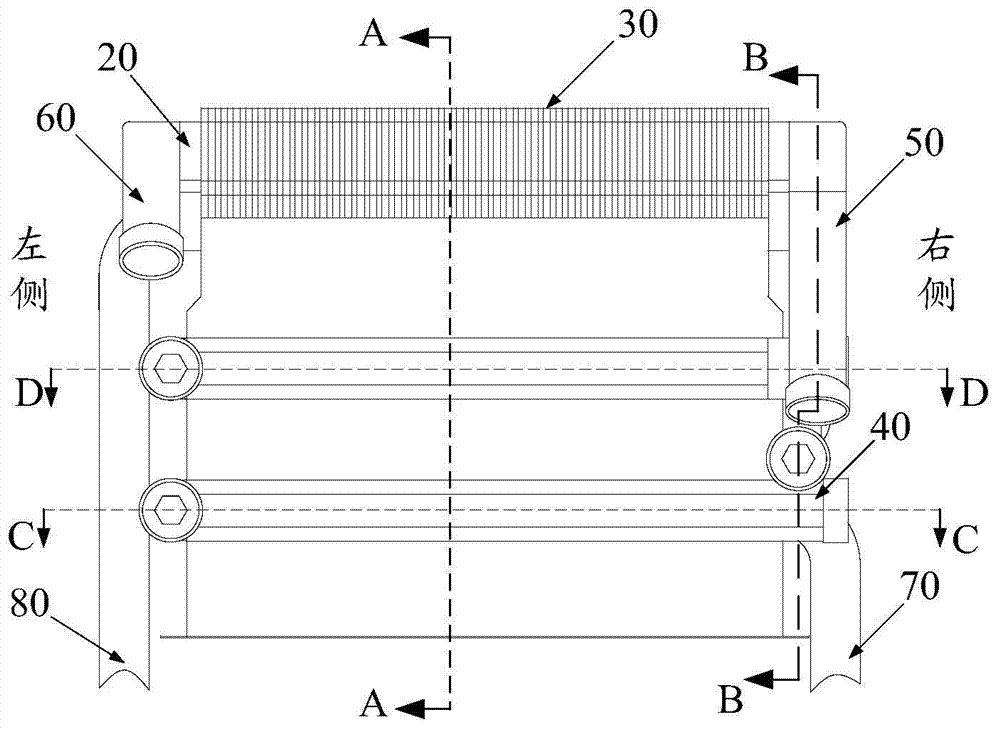

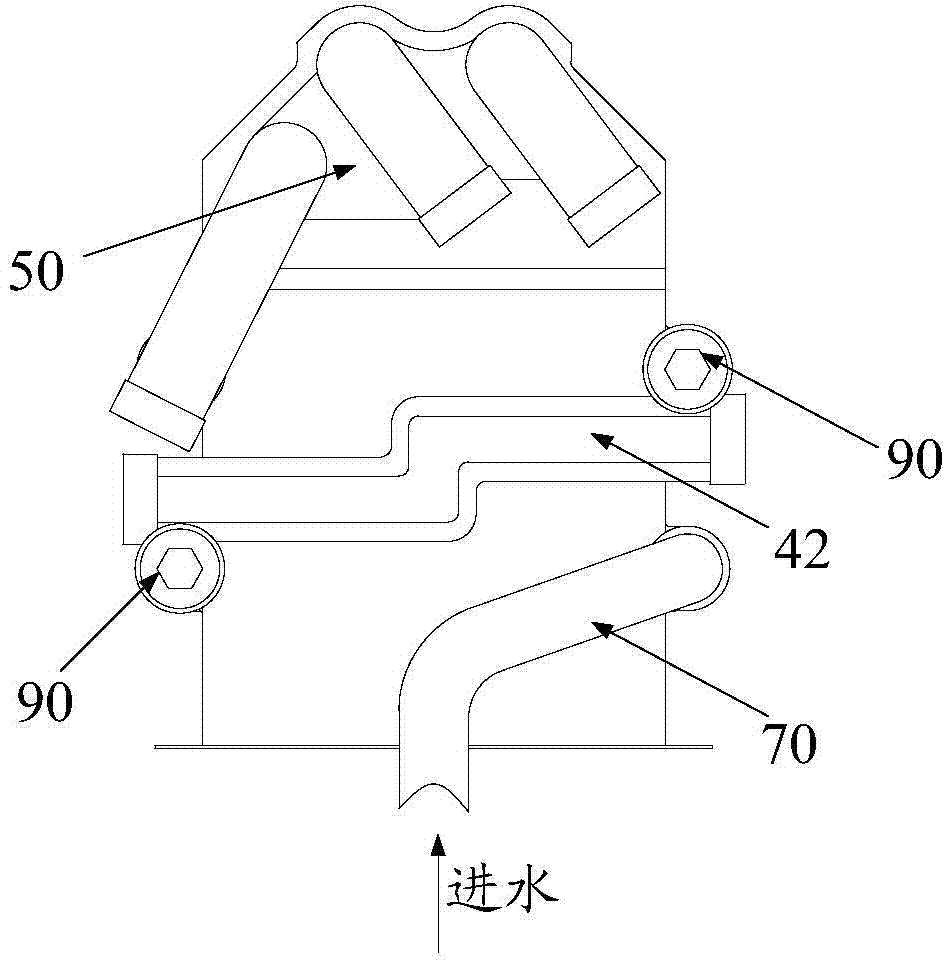

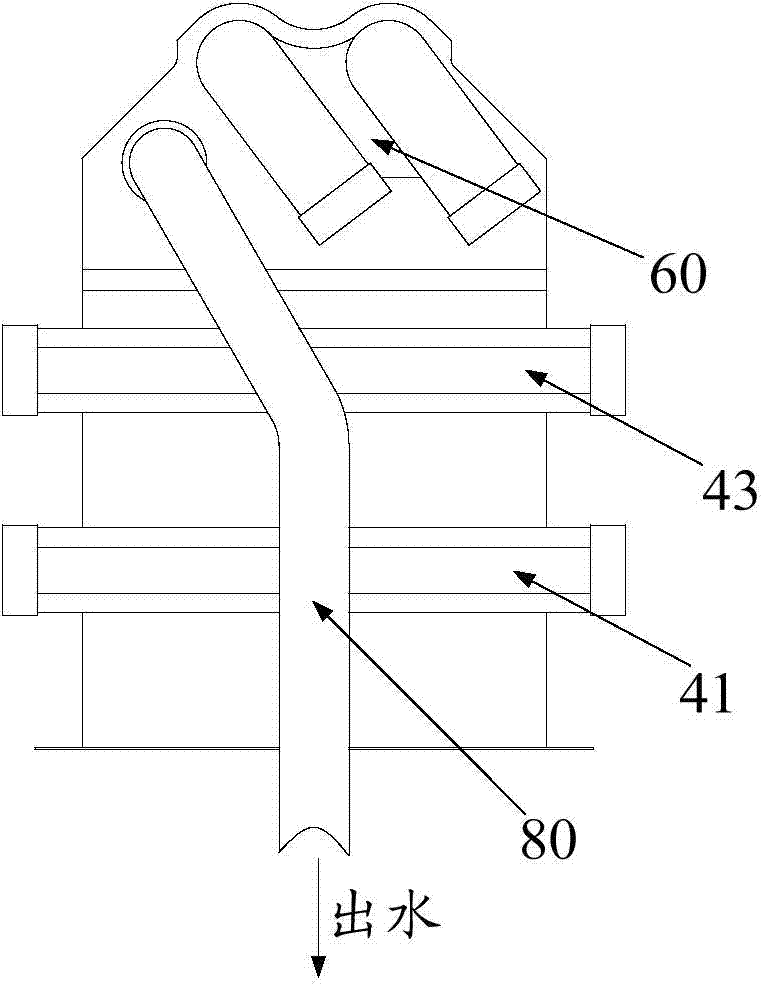

[0046] The invention provides a heat exchanger. Such as Figure 1 to Figure 3 as shown, figure 1 It is a schematic diagram of the front view structure of the heat exchanger of the present invention; figure 2 for figure 1 The structural schematic diagram of the right side view of the heat exchanger shown; image 3 for figure 1 Shown is a structural schematic diagram of the left side view of the heat exchanger of the present invention. The heat exchanger includes a heat exchange main body, a left end cover 60 , a right end cover 50 , a water inlet pipe 70 , a water outlet pipe 80 and a plug 90 .

[0047] Specifically, such as Figure 4 to Figure 6 as shown, Figure 4 for figure 1 The schematic diagram of the cross-sectional structure of the heat exchanger along the line A-A; Figure 5 for figure 1 The schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com