Analysis system and method of medium motion state in ball mill

A medium motion and analysis system technology, applied in the direction of navigation and grain processing through velocity/acceleration measurement, can solve the problems of camera lens pollution, dim light, large errors, etc., to reduce energy consumption and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

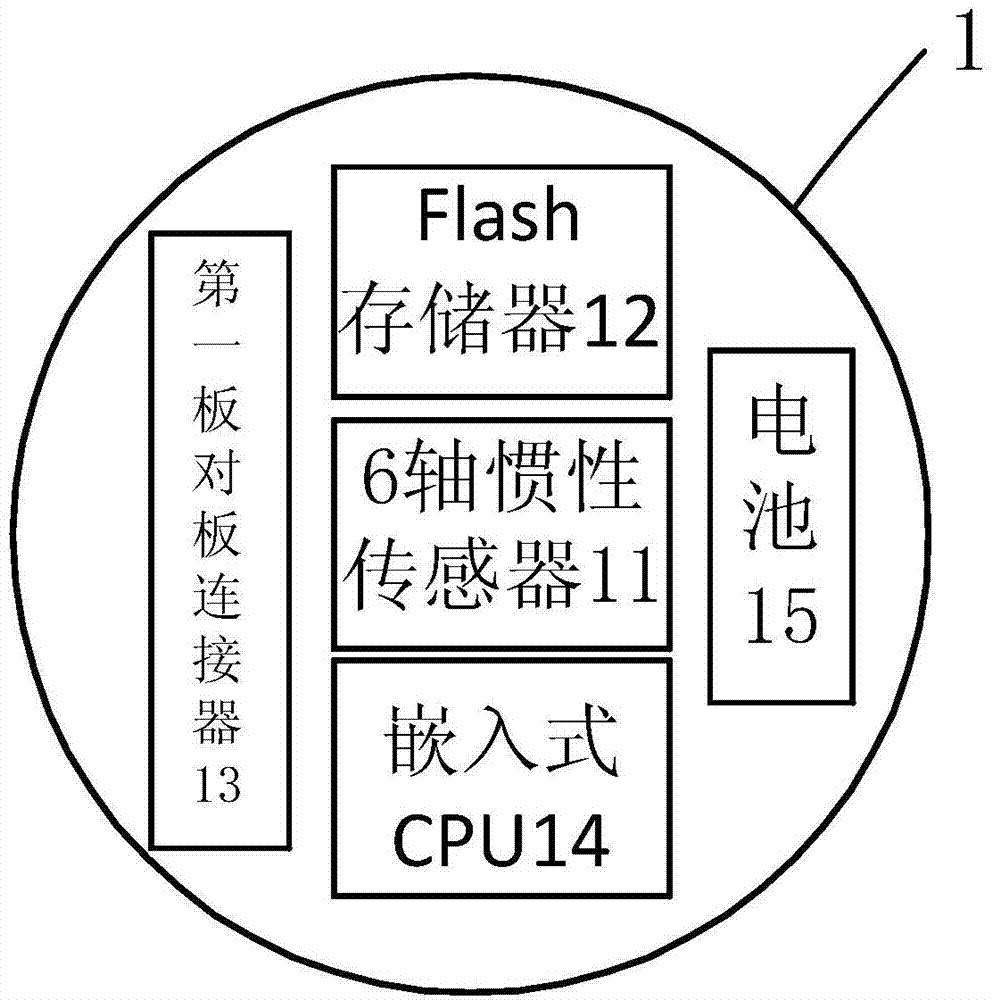

[0037] The analysis system of the motion state of the medium in the ball mill of the present invention includes a plurality of ball mill sensors 1 and a host computer; each ball sensor 1 sends the collected data of the motion state of the medium in the ball mill to the host computer, and the host computer checks the grinding balls. The motion state data is analyzed and processed; wherein, the medium motion state data includes time stamp, 3-axis acceleration and 3-axis angular velocity.

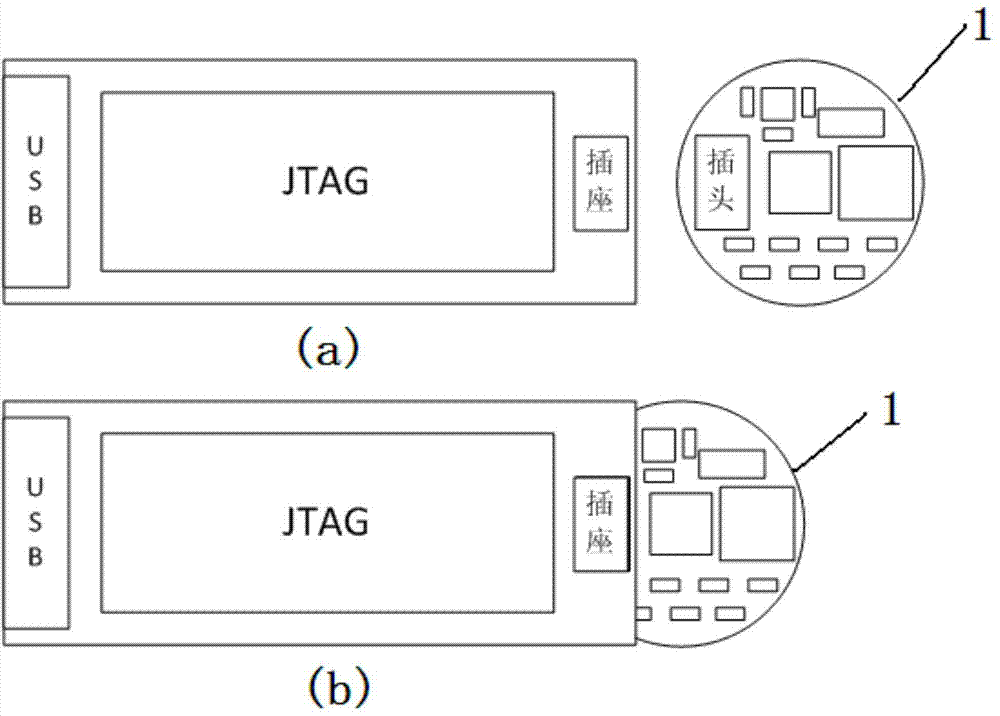

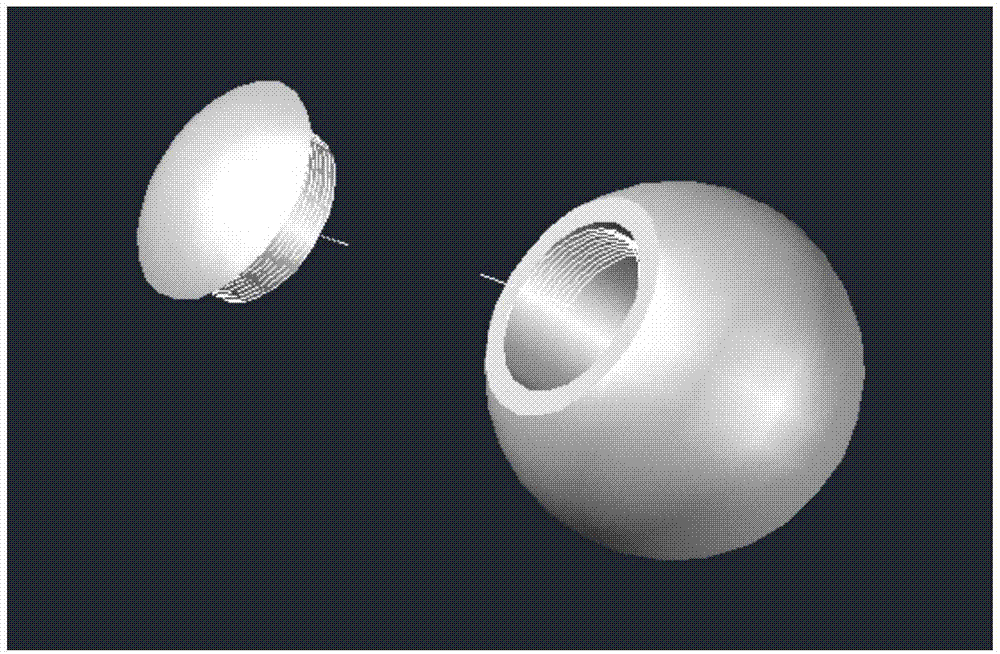

[0038] Such as figure 1 As shown, the ball sensor 1 of the present invention includes a 6-axis inertial sensor 11, a Flash memory 12, a first board-to-board connector 13, an embedded CPU 14 and a battery 15, wherein the 6-axis inertial sensor 11, The Flash memory 12, the first board-to-board connector 13 and the embedded CPU 14 are all fixedly arranged on a circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com