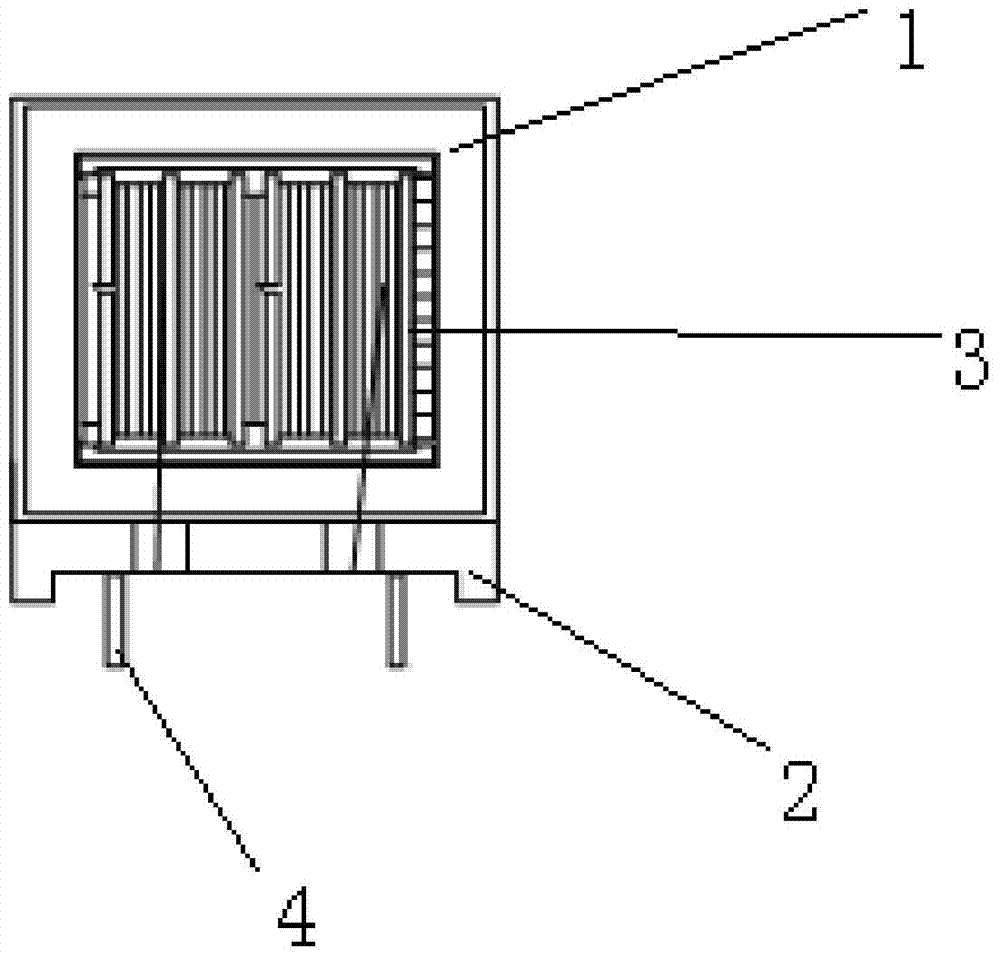

ET type filter inductor

A filter inductor, ET24R10K technology, applied in the field of inductors, can solve problems such as difficult assembly, increased volume of filter inductors, and increased core volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. An ET-type filter inductor, comprising a magnetic core, a skeleton, an enameled wire and pins, the two ends of the magnetic core and the skeleton are fixedly connected by glue, the enameled wire is wound on the skeleton, and the pins are arranged on The end of the skeleton, the material of the magnetic core is ET24R10K, the material of the skeleton is ET24PBT, and also includes a base, the base is located at the end of the magnetic core, and is fixedly connected with the magnetic core, and the pins are located at The lower end of the base has the following processes: magnetic core loading, winding, assembly, primary tinning, varnish dipping, glue dispensing, baking, secondary tinning, printing, pressure resistance, testing, external inspection, and inspection. The overall length of the magnetic core described is 30mm. The winding method is to arrange the wires in a clockwise direction, and the glue is E51 epoxy.

[0014] 2. An ET-type filter inductor, including a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com