A zinc-nickel dual-liquid flow battery

A flow battery, zinc-nickel technology, applied in the direction of alkaline battery electrodes, etc., can solve the problem of corrosion and pollution of strong alkaline electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Electrolyte preparation

[0027] Positive electrode electrolyte: Weigh 2.806g KOH, dissolve in deionized water, dilute to 50mL, and prepare 1mol L -1 KOH aqueous solution.

[0028] Negative electrode electrolyte: weigh 14.35g ZnSO 4 ·7H 2 O, dissolved in deionized water, dilute to 50mL, and make 1molL -1 ZnSO 4 aqueous solution.

[0029] The third solution in the ring frame: prepare 1mol L -1 K 2 SO 4 Aqueous solution 50mL.

[0030] Battery Assembly:

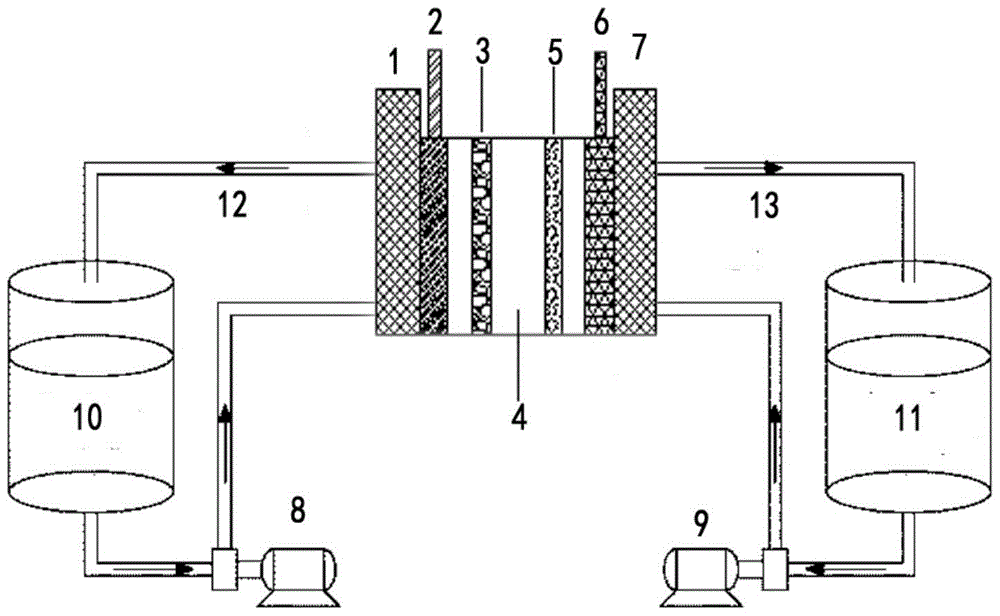

[0031] The single cell is (1) positive terminal plate, (2) positive electrode (sintered nickel electrode 3x3cm 2 ), (3)-cation exchange membrane Nafion117, 4-annular frame, 5-anion exchange membrane Aciplex A221, 6-negative electrode (graphite plate 3x3cm 2 ), 7-negative terminal plate, 8,9-pump, 10-positive liquid storage tank, 11-negative liquid storage tank, 12,13-pipeline; single battery structure and system see figure 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com