Waveguide 90-degree turning structure with polarization turning function

A horizontally polarized wave and waveguide technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of large volume, no torsional polarization, system performance and reliability degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

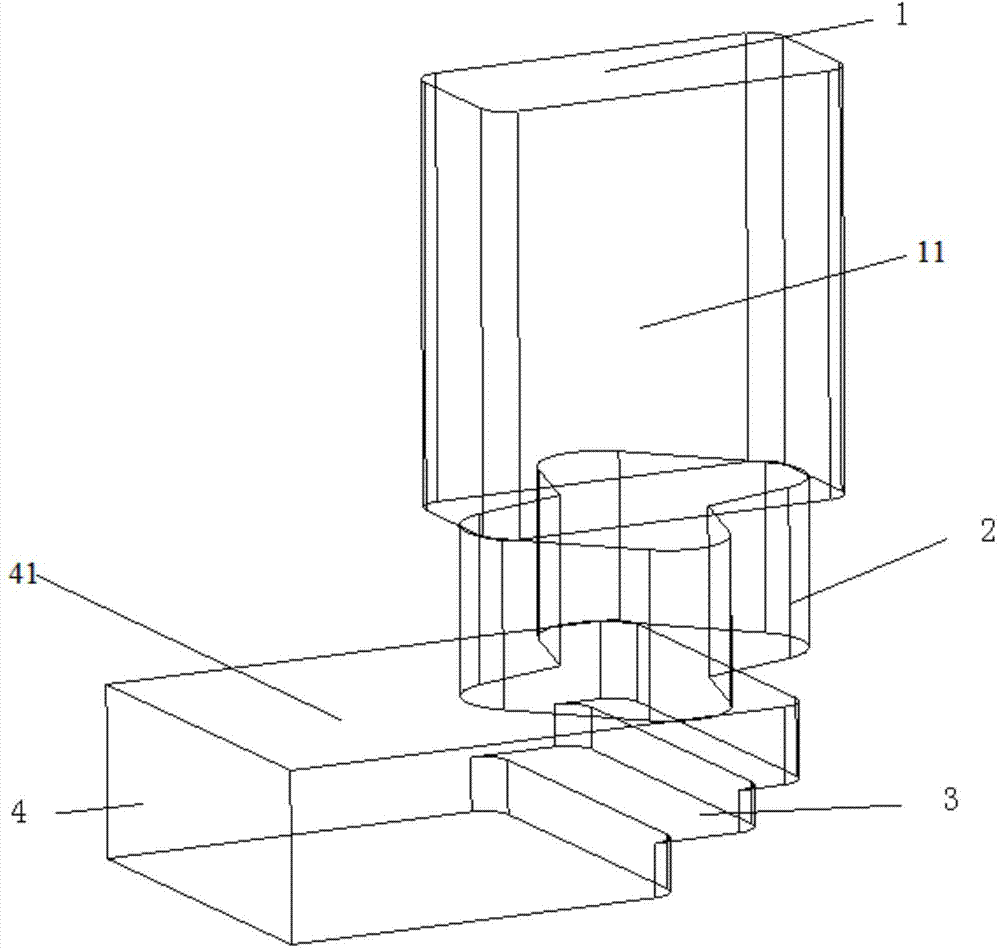

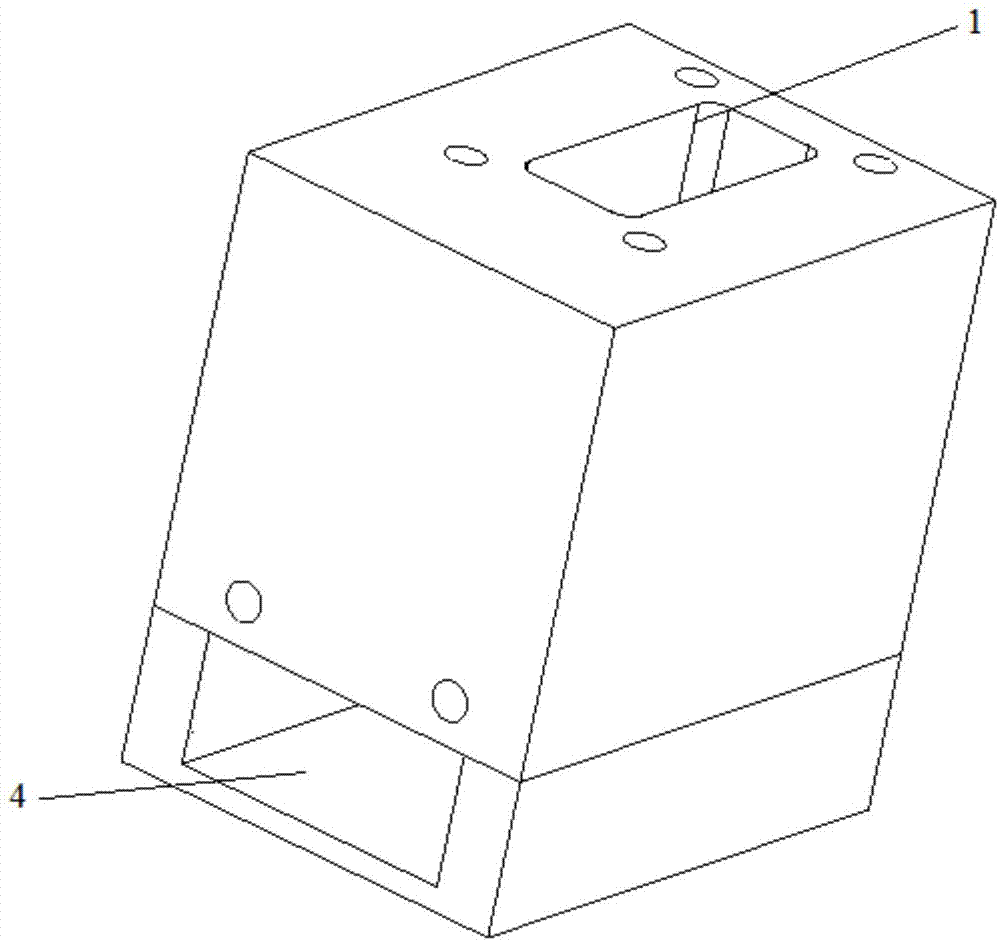

[0014] like figure 1 , 2 A 90-degree turning structure of a waveguide with polarization reversing function is shown, including a body, on which there are rectangular horizontally polarized waveguides 11 and rectangular vertically polarized waveguides 41 perpendicular to each other, and the rectangular horizontally polarized waveguides The tube 11 and the rectangular vertically polarized waveguide 41 are connected through a butterfly-shaped cavity 2 and a three-level vertical step structure 3 . The rectangular horizontally polarized waveguide port 1 and the rectangular vertically polarized waveguide port 4 are symmetrical along the center line of the body.

[0015] In order to facilitate processing, the turning structure is composed of two metal parts, the rectangular horizontally polarized waveguide 11 and the multi-level step structure 3 are processed in one part, and the rectangular vertically polarized waveguide 41 and the butterfly cavity 2 are processed inside another c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com