Casting method of mud pump air dome shell for bearing pressure

A technology of air bag and mud pump, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of high production cost and difficult processing, and achieve the effect of reducing production cost, solving difficult processing and compact structure

Active Publication Date: 2015-06-24

BAOJI PETROLEUM MASCH CO LTD

View PDF6 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0076] Make the shell of KB-75 air bag, drawing number AK753501-0301B1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

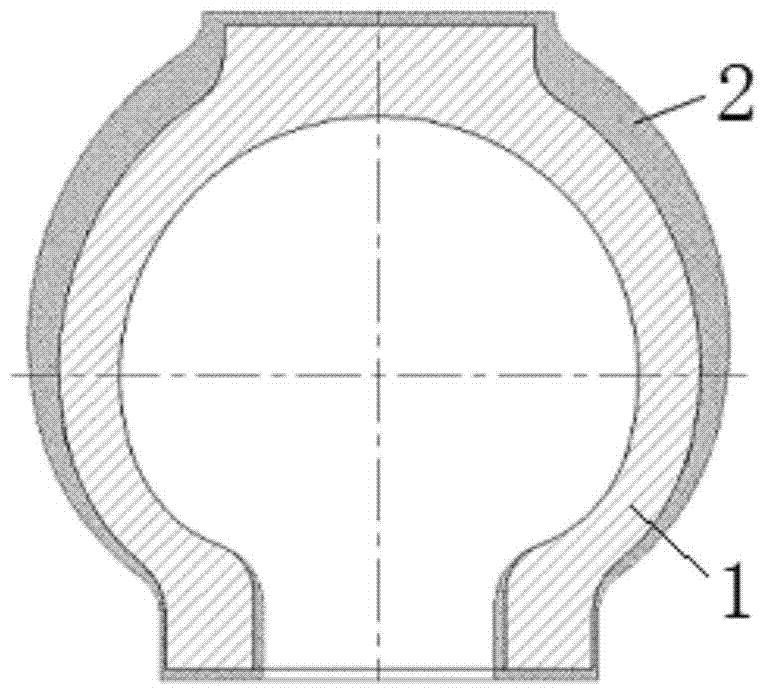

The invention discloses a casting method of a mud pump air dome shell for bearing pressure. The method comprises the following steps: step one. setting process, namely selecting the air dome shell with a downward big opening; optimizing working allowance layer on an outer sphere of the air dome shell; manufacturing a sphere sand core and a core head and a corresponding fixing rod; arranging a thermal-preservation open riser on the top end of the air dome shell; arranging two chilling blocks at the opening end of the air dome shell; installing a pouring runner; and drawing an art work sheet; step two, casting, namely manufacturing a wood core box for a solid pattern and the ball-shaped spherical sand core and the core head; modeling, taking out the solid pattern to form a cavity; manufacturing the spherical sand core, the core head, and a sand core skeleton, and placing an exhaust rope; spraying the paint; carrying out mold assembling, baking a sand mold, pouring, opening the mold; primarily blasting sand; grinding and repairing; normalizing, secondarily blasting sand to obtain the product. Through the adoption of the method disclosed by the invention, the manufactured air dome shell is high in cast precision, and the production cost is obviously reduced.

Description

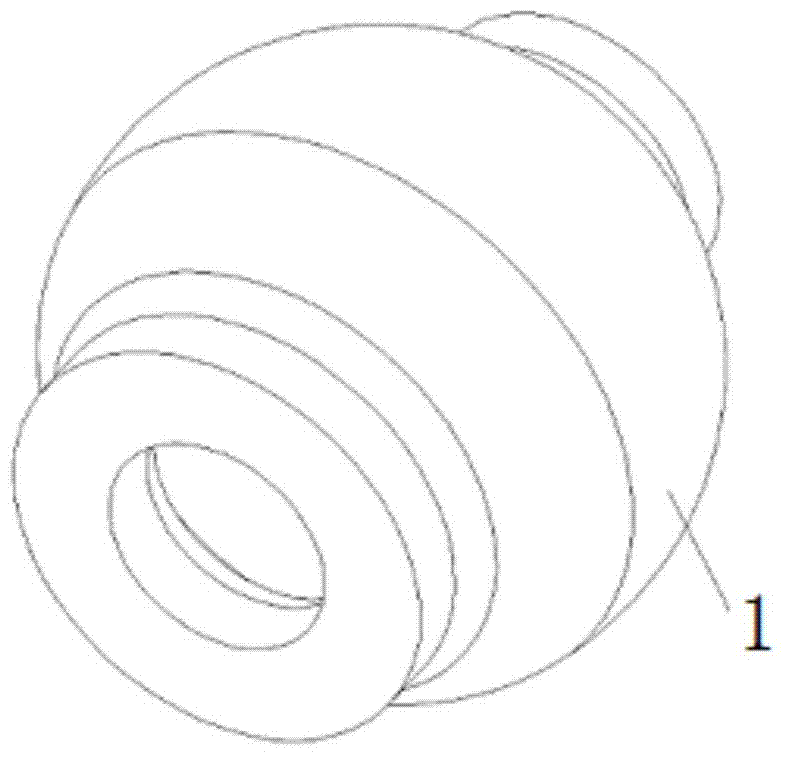

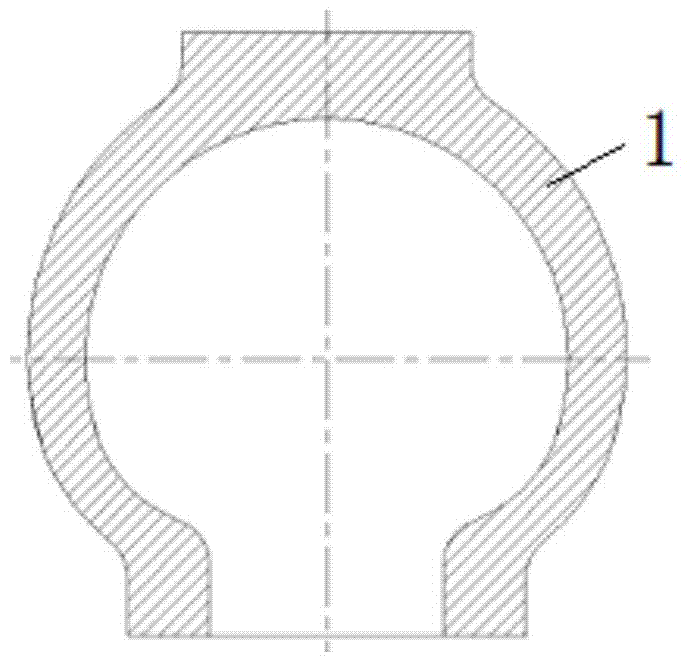

technical field [0001] The invention belongs to the technical field of mechanical equipment manufacturing and relates to a casting method for an air bag casing of a mud pump for pressure bearing. Background technique [0002] The air bag is an important part of the mud pump of oil drilling equipment. It plays the role of stabilizing the pressure and reducing the fluctuation during the drilling process. The air bag shell is the part that mainly plays the role of protection and pressure bearing. refer to figure 1 , figure 2 , the shape of the air bag shell 1 is a hollow sphere, and the technical requirements are: magnetic particle flaw detection on the inner and outer surfaces, volumetric nondestructive testing, and hydrostatic pressure test with a pressure of 52Mpa. [0003] In order to ensure product quality, it is generally made of forgings, and the material is 35CrMoA. However, the air bag shell forged in this way is difficult to machine in the later stage, and the prod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C9/24B22C9/08

CPCB22C9/08B22C9/24

Inventor 李继峰李保峰马崇峰王高社宋伟

Owner BAOJI PETROLEUM MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com