Bilge well for ship

A technology for sewage wells and ships, which is used in the direction of pipelines, hulls, and ship parts for emptying/ballasting, and can solve problems such as difficult dismantling, large manufacturing processes, and complexity, and achieves convenient installation, maintenance, and disassembly, and shortens working hours , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

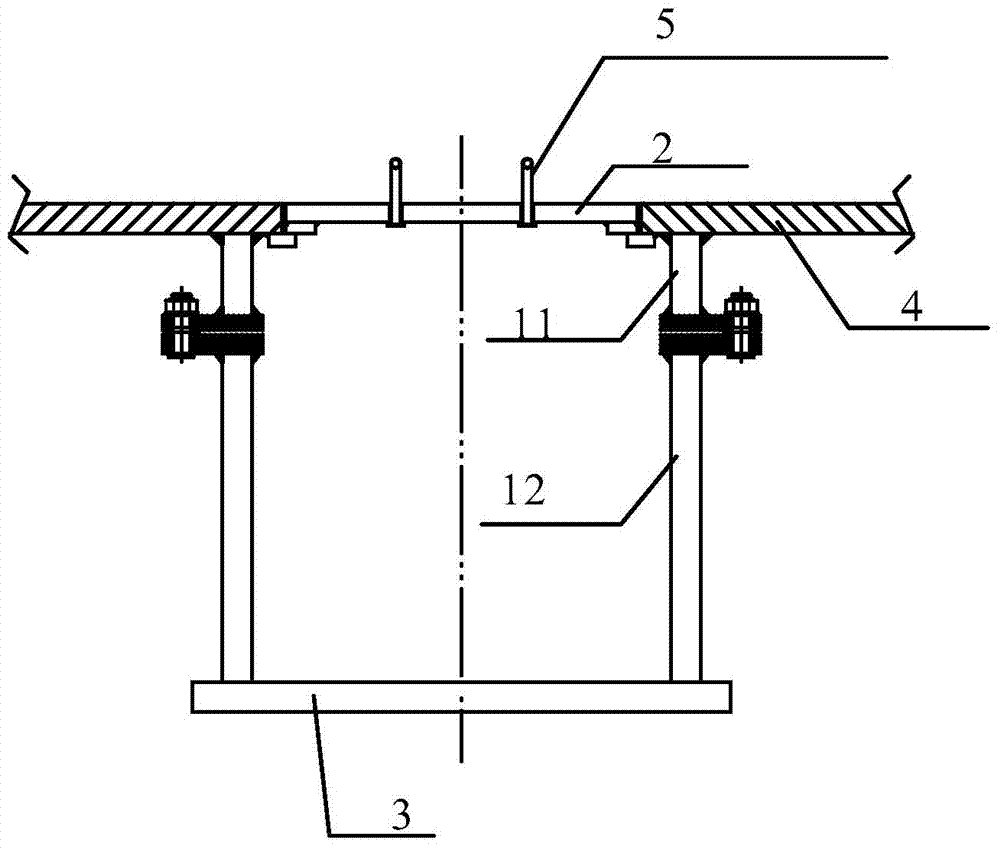

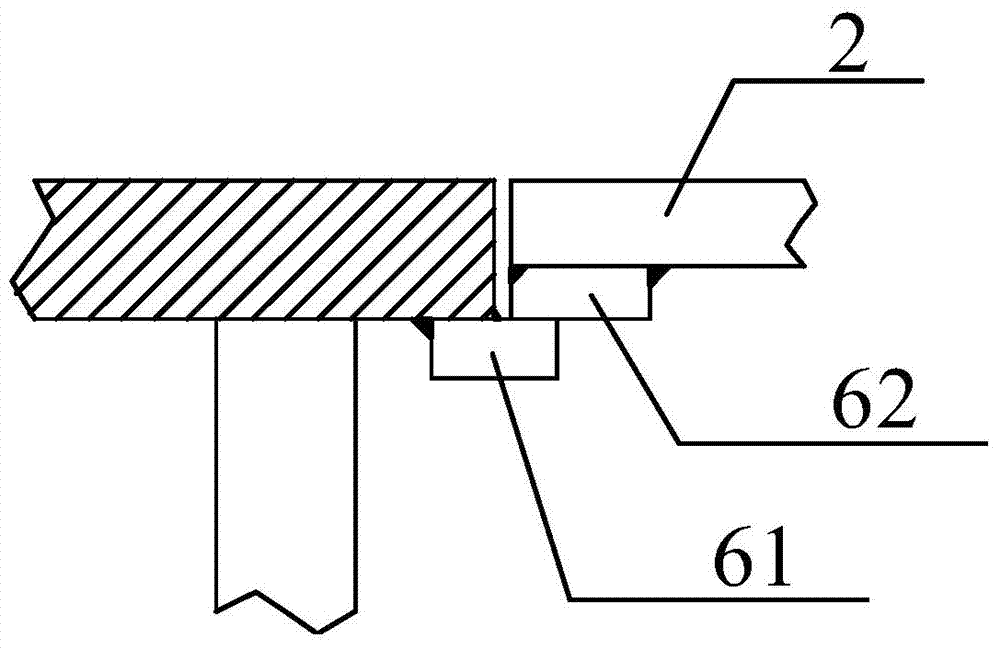

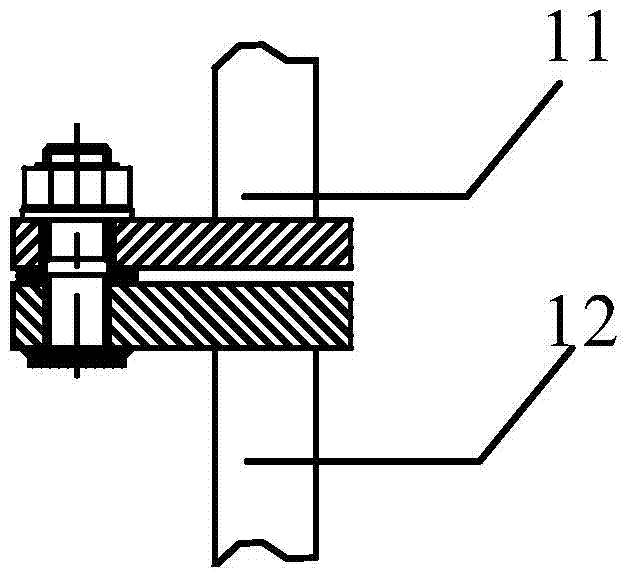

[0029] figure 1 It is a structural schematic diagram of a section of a sewage well for a ship in this embodiment, figure 2 It is a schematic diagram of the connection structure between the well body and the bilge of the present embodiment, image 3 It is a schematic diagram of the connection structure of the upper well body and the lower well body of the present embodiment, as Figure 1~3 As shown, the sewage well for ships involved in this embodiment includes an upper well body 11, a lower well body 12, a well cover 2 and a well floor 3, and the upper well body 11 and the lower well body 12 are cylindrical steel pipes with the same diameter. The lower end of the body 11 and the outer circumference of the upper end of the lower well body 12 are welded with wings, and these wings are fixed by bolts so that the upper well body 11 and the lower well body 12 are fixed.

[0030] The lower well body 12 and the well bottom plate 3 are welded and combined in the workshop first, and...

Embodiment 2

[0036] Figure 4 It is a structural schematic diagram of a section of a sewage well for a ship according to Embodiment 2 of the present invention, Figure 5 It is a schematic diagram of the connection structure between the upper well body and the bilge of Embodiment 2 of the present invention, as Figure 4~5 As shown, the difference between this embodiment and Embodiment 1 is that the outer periphery of the upper end of the upper well body 11 is welded to the bilge 4, and the inner circumference of the upper end of the upper well body 11 is ring-shaped with several pads 63, and the pads 63 Used to support manhole cover 2.

Embodiment 3

[0038] Figure 6 It is the structural representation of the cross-section of the sewage well used for ships of the present embodiment, as Figure 6 As shown, the difference between this embodiment and Embodiment 2 lies in that the upper well body 11 and the lower well body 12 are connected and fixed with their axes forming an obtuse angle.

[0039] This embodiment can better solve the problem of limited construction space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com