Energy-saving and environmentally friendly glass wine bottle production method and glass wine bottle melting furnace

An energy-saving and environmentally friendly production method technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of raw material dust pollution, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

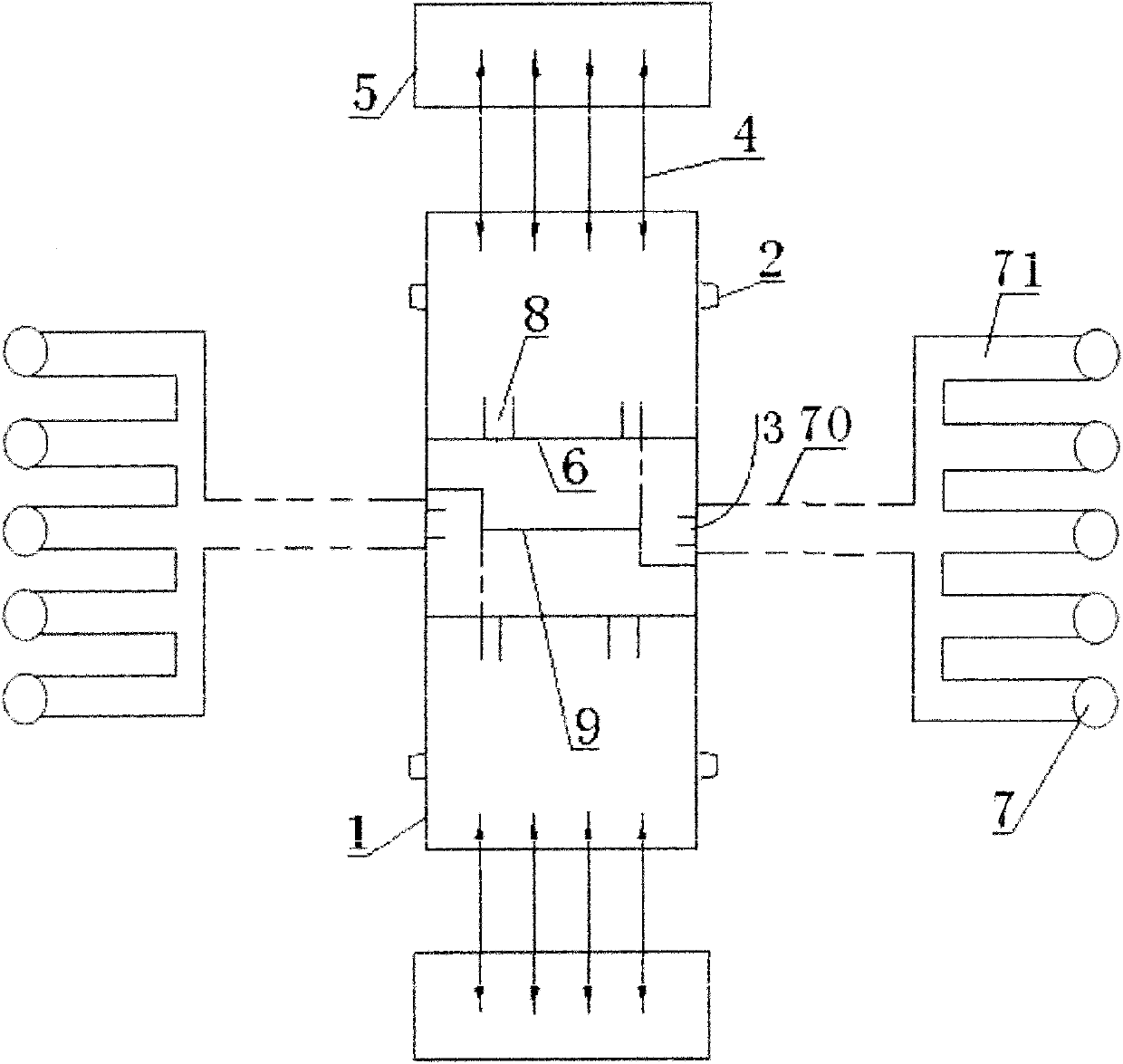

[0024] The production method of the energy-saving and environment-friendly glass wine bottle of the present invention utilizes the relatively distributed small furnaces arranged on the breast walls of the two short sides of the rectangular melting furnace that is long in the longitudinal direction and short in the horizontal direction, and the long-diameter longitudinal flames produced by the regenerator equipped with a commutator at regular intervals The glass frit in the melting pool of the melting furnace is melted and heated, and the glass wine bottles are fed through a pair of feeding ports on both sides of the middle of the long side of the melting pool through a main feeder and five distribution channels in the same direction as the main feeder. The forming machine supplies glass liquid. The feeding efficiency and production capacity are improved by arranging a total of four relatively side-by-side end feeding ports at both ends of the two long side parapets of the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com