Piezoelectric ceramics with bismuth layered structure, preparation method thereof and method for improving high temperature resistivity of bismuth layered piezoelectric ceramics

A piezoelectric ceramic, high resistivity technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as performance defects, optimize dielectric and piezoelectric properties, improve The effect of high temperature resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

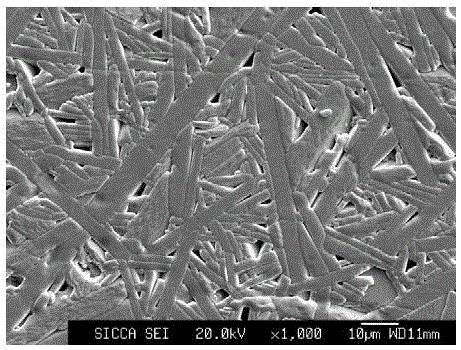

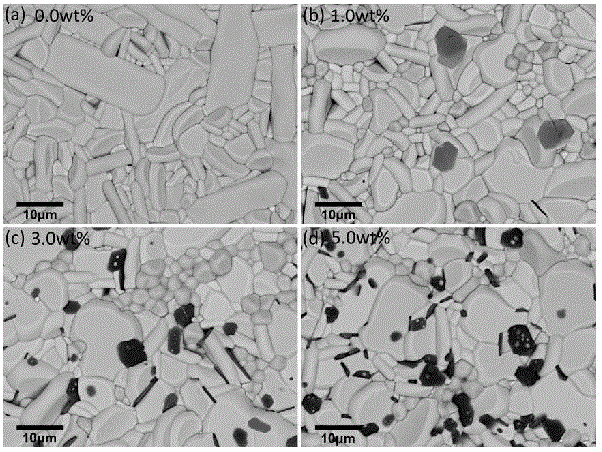

[0030] Al was prepared by solid-state reaction method 2 o 3 doped bismuth layered Na 0.5 Bi 2.5 Nb2 o 9 Piezoelectric Ceramics. Among them, Al 2 o 3 The purity of the powder raw material is 99.95%, and its addition amount is Na 0.5 Bi 2.5 Nb 2 o 9 1.0% of the weight of piezoelectric ceramic powder, added in the form of Na after synthesis 0.5 Bi 2.5 Nb 2 o 9 The powders are finely ground together, then formed and sintered (sintering temperature 1150°C, sintering time 2 hours, heating rate 3°C / min) and other processes.

Embodiment 2

[0032] Al was prepared by solid-state reaction method 2 o 3 doped bismuth layered Na 0.5 Bi 2.5 Nb 2 o 9 Piezoelectric Ceramics. Among them, Al 2 o 3 The purity of the powder raw material is 99.95%, and its addition amount is Na 0.5 Bi 2.5 Nb 2 o 9 3.0% of the weight of piezoelectric ceramic powder, added in the form of Na after synthesis 0.5 Bi 2.5 Nb 2 o 9 The powders are finely ground together, then formed and sintered (sintering temperature 1150°C, sintering time 2 hours, heating rate 3°C / min) and other processes.

Embodiment 3

[0034] Al was prepared by solid-state reaction method 2 o 3 doped bismuth layered Na 0.5 Bi 2.5 Nb 2 o 9 Piezoelectric Ceramics. Among them, Al 2 o 3 The purity of the powder raw material is 99.95%, and its addition amount is Na 0.5 Bi 2.5 Nb 2 o 9 5.0% of the weight of piezoelectric ceramic powder, added in the form of Na after synthesis 0.5 Bi 2.5 Nb 2 o 9 The powders are finely ground together, then formed and sintered (sintering temperature 1160°C, sintering time 2 hours, heating rate 3°C / min) and other processes.

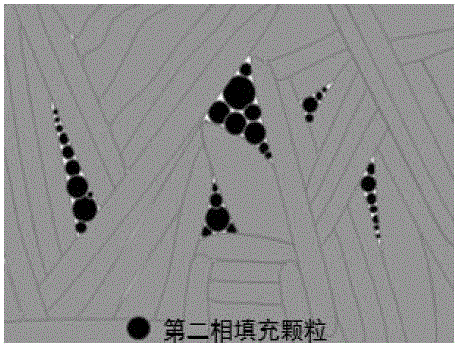

[0035] image 3 for different Al 2 o 3 Doping modified Na 0.5 Bi 2.5 Nb 2 o 9 From the natural surface morphology of ceramics, it can be seen that the second phase is formed at the grain boundary, which plays a role in filling the voids and pores. Density; on the other hand, these second-phase particles at the grain boundaries also have the effect of hindering the current channel, which is beneficial to increase the resistivity.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com