Rubidium-and-cerium co-doped calcium bismuth niobate-based high-temperature piezoelectric ceramic and preparing method thereof

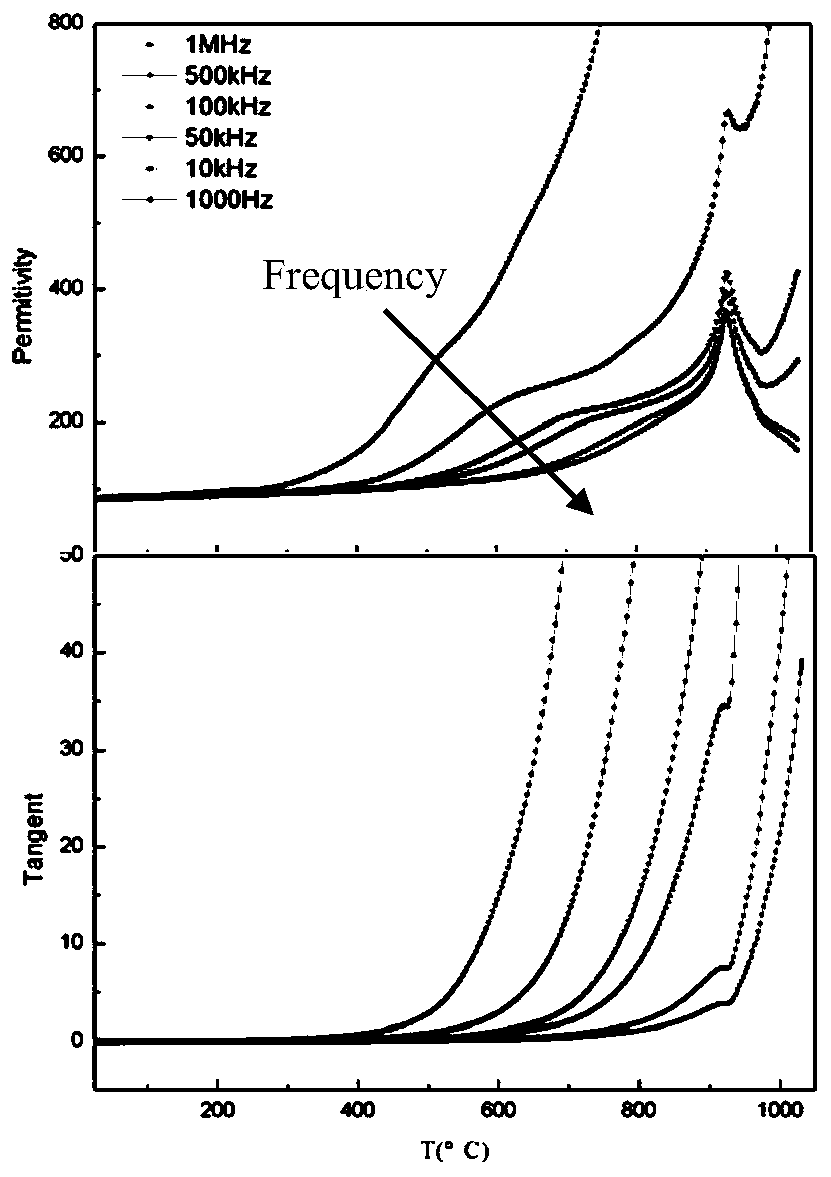

A calcium bismuth niobate-based, high-temperature piezoelectric technology, applied in the field of electronic ceramics and piezoelectric devices, can solve the problems of low piezoelectric performance and high Curie temperature, and achieve high-voltage electrical coefficient, high Curie temperature, and excellent piezoelectric performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

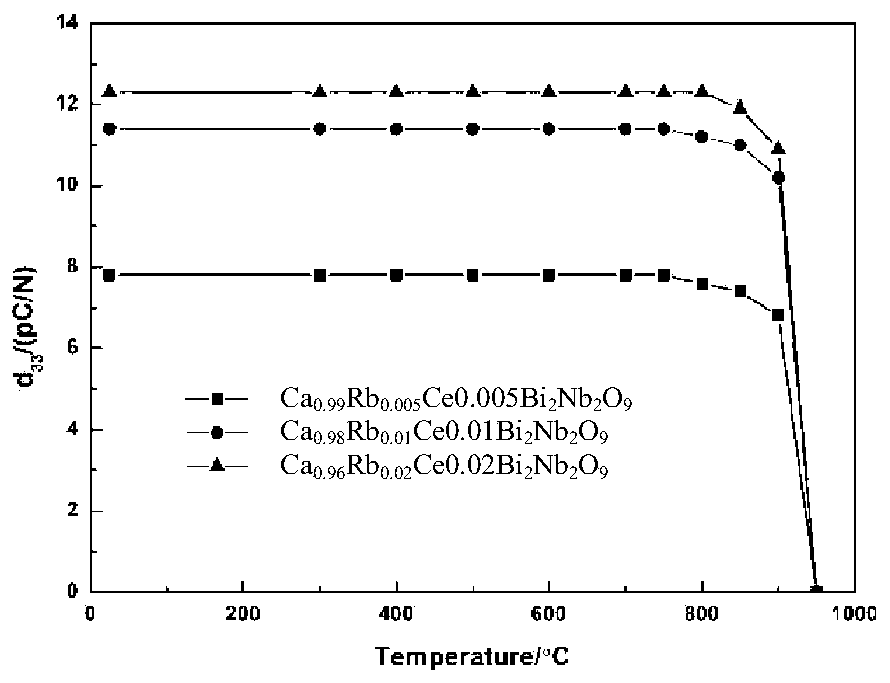

Embodiment 1

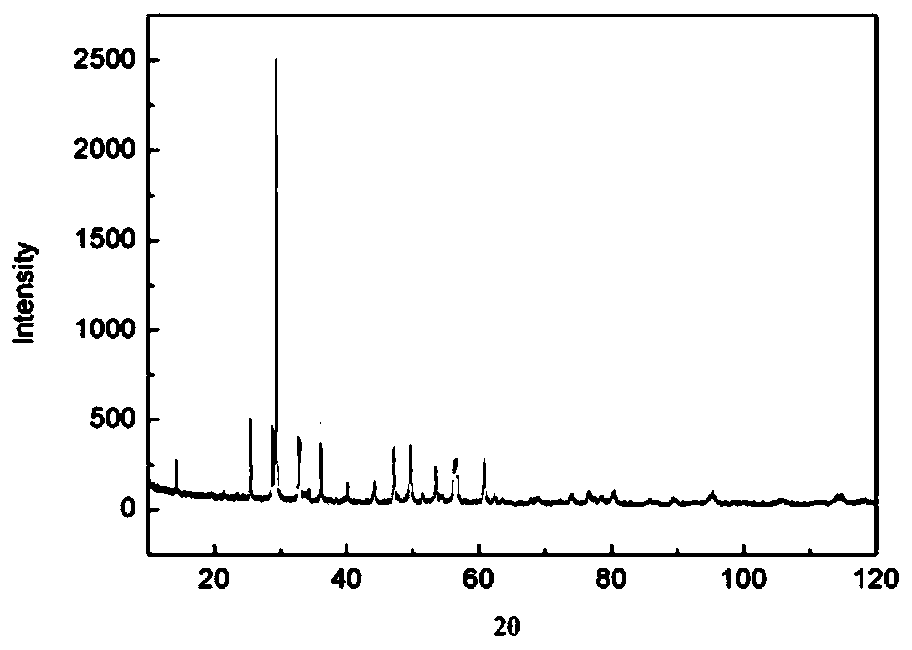

[0034] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0035] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.005) weighed the ingredients, took absolute ethanol as the dispersion medium, put it in a nylon ball mill jar, and used a planetary ball mill to mill for 4 hours at a speed of 360rmp to obtain a mixed powder;

[0036] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 900° C. in a box furnace and keep it warm for 2 hours to obtain bismuth-calcium niobate-based ceramic powder;

[0037] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0038] (4) Dry the powder after secondary ball milling, add 5wt% PVA to granulate,...

Embodiment 2

[0043] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0044] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.01) weighed the ingredients, took absolute ethanol as the dispersion medium, put it in a nylon ball mill jar, and used a planetary ball mill to mill for 4 hours at a speed of 360rmp to obtain a mixed powder;

[0045] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 950° C. in a box furnace, and keep it warm for 2 hours to obtain bismuth calcium niobate-based ceramic powder;

[0046] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0047] (4) Dry the powder after secondary ball milling and add 5wt% PVA to granula...

Embodiment 3

[0052] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0053] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.02) is weighed and batched, with absolute ethanol as the dispersion medium, put in a nylon ball mill jar, and use a planetary ball mill to mill for 4 hours at a speed of 360rmp to obtain a mixed powder;

[0054] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 950° C. in a box furnace, and keep it warm for 2 hours to obtain bismuth calcium niobate-based ceramic powder;

[0055] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0056] (4) Dry the powder after secondary ball milling and add 5wt% PVA to granulate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com