Modified concrete superposition board floor structure with shear keys and connection method

A connection method and shear key technology, applied in floors, building components, building structures, etc., can solve problems such as equivalent transfer of bending moment and tensile stress of steel bars at the bottom of difficult slabs, achieve equivalent transfer, increase contact area, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

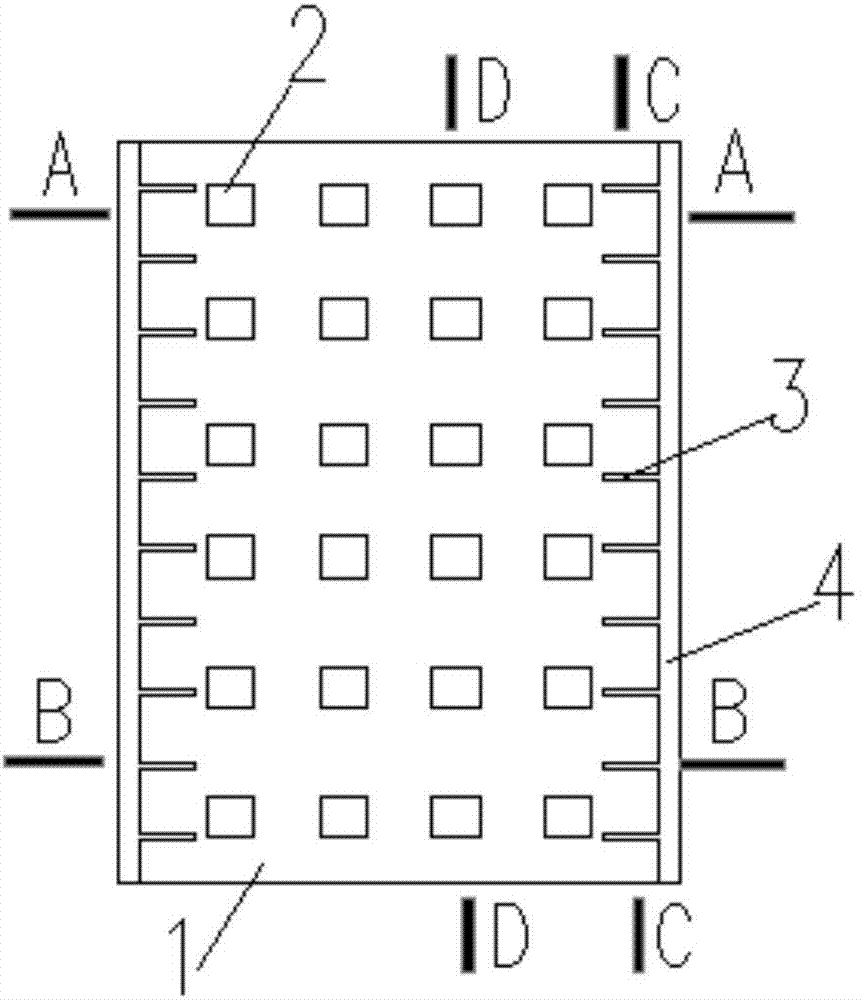

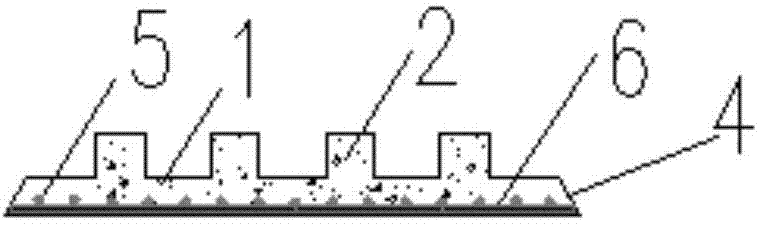

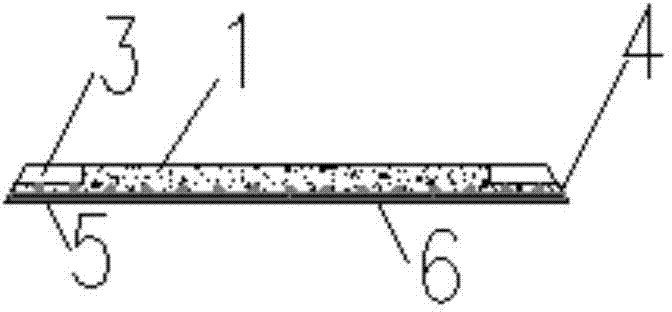

[0040] The original concrete laminated slab consists of cast-in-place floors and prefabricated bottom slabs set up above and below. Shear keys are provided on the prefabricated bottom slabs. How to connect between concrete laminated slabs and beams. The improved concrete laminated slab floor structure and connection method with shear key of the present invention, its design idea is as follows:

[0041] (1) Change the two sides of the prefabricated bottom slab of the original concrete laminated slab floor with shear keys into slopes with a certain inclination angle to the bottom surface, and set lapped reinforcement grooves on both sides of the prefabricated bottom slab, and the four sides of the prefabricated bottom slab Both changed to rough surface.

[0042] (2) The two sides of the prefabricated floor and the bottom of the slab have a certain inclination angle, which can increase the contact area between the side of the prefabricated floor and the cast-in-place layer, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com