Concrete vibrating rod

A technology of concrete and vibrating rods, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of large heat loss and energy waste, and achieve the effects of energy saving, easy operation, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

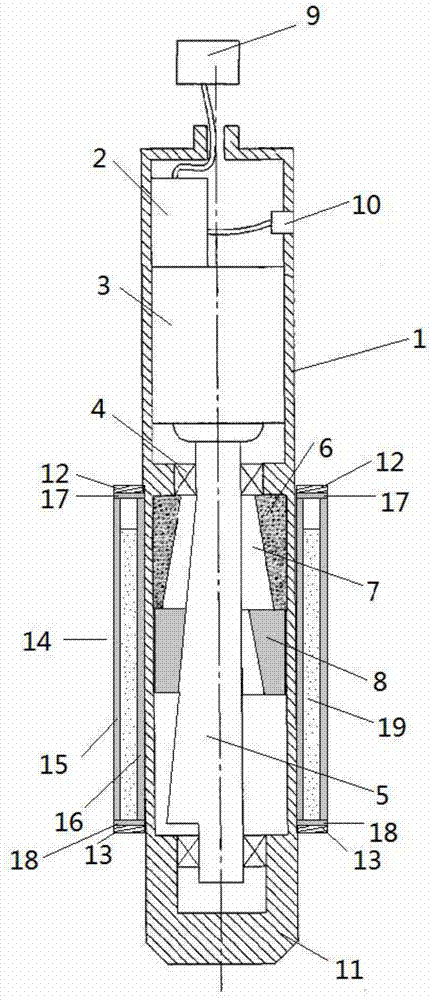

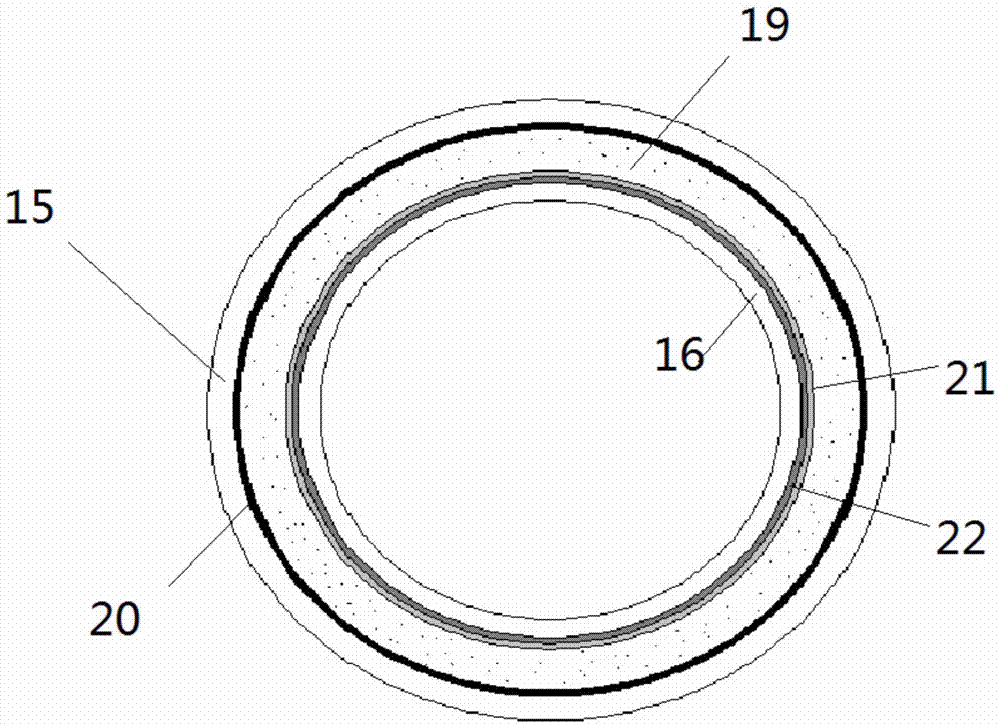

[0043] Such as figure 1 , figure 2As shown, a concrete vibrating rod includes a shell 1, an eccentric shaft 5, a bearing seat 4, an AC motor 3, a frequency conversion controller 2, a muffler sleeve 6, a rod head 11, a sound sensor 10, a connecting part, a heating phase Change cover 14, temperature sensor. The inside of the housing 1 is divided into two chambers, upper and lower, which are separated by the bearing seat 4 . The upper room is provided with a frequency conversion controller 2 and an AC motor 3, the frequency conversion controller 2 is connected to an AC power supply 9, and the frequency conversion controller 2 is connected to the AC motor 3 for controlling the speed of the AC motor 3. The upper end of the eccentric shaft 5 is connected with the output shaft of the AC motor 3, and the upper part of the eccentric shaft 5 is positioned inside the housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com