Inertial-separation and automatic-collection type oil fume purifying system

A technology of automatic collection and inertial separation, which is applied in the field of inertial separation and automatic collection of oil fume purification systems, can solve the problems of oil fume purification systems that are unfavorable for environmental protection, increase in power consumption, secondary pollution, and loss of activated carbon, and achieve environmental protection. Reasonable design, avoiding the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

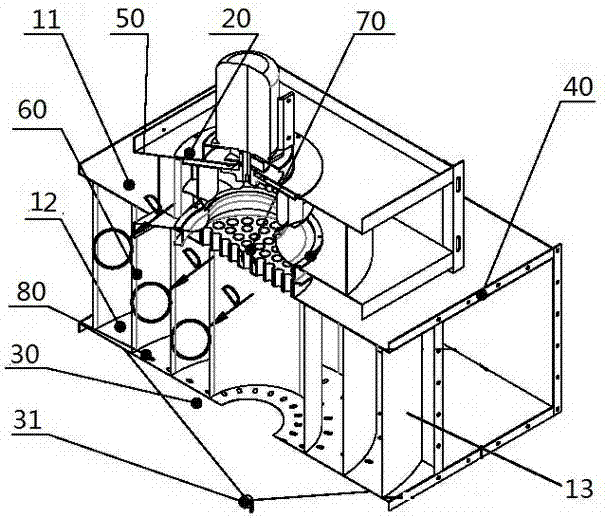

[0023] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

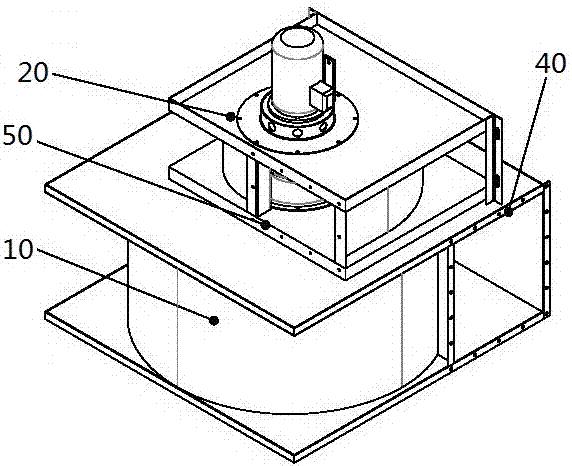

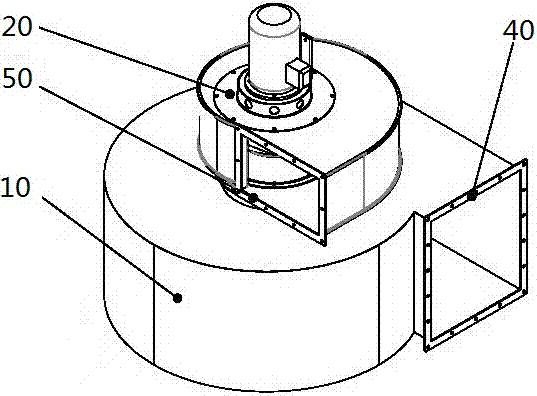

[0024] like Figure 1-10 As shown, the structure diagram of the inertial separation and automatic collection fume purification system of the preferred embodiment of the present invention, the inertial separation and automatic collection fume purification system of the present invention includes a main body 10, a fan 20 located above the main body 10, and a fan 20 located above the main body 10. The cone-shaped container 30 below, preferably, the main body 10 is square or snail-shaped, so that th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap