Beam and groove combined stepped island film micropressure sensor chip and manufacturing method thereof

A micro-pressure sensor, step-type technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve problems such as inability to adapt to and cannot meet the measurement requirements in the aerospace field, stay and other problems, achieve reasonable structure, realize mass production, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

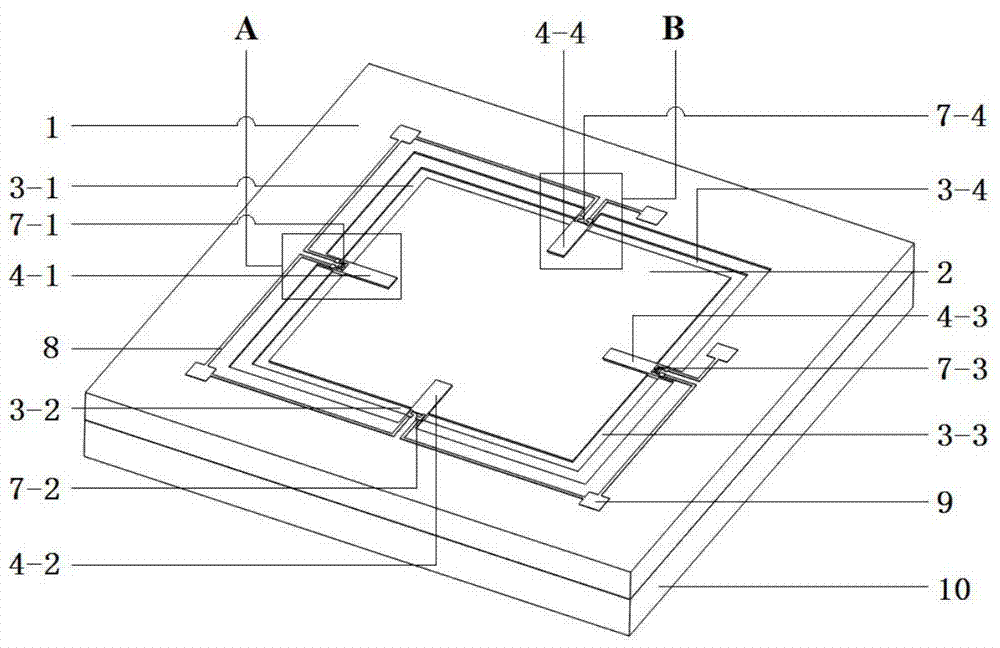

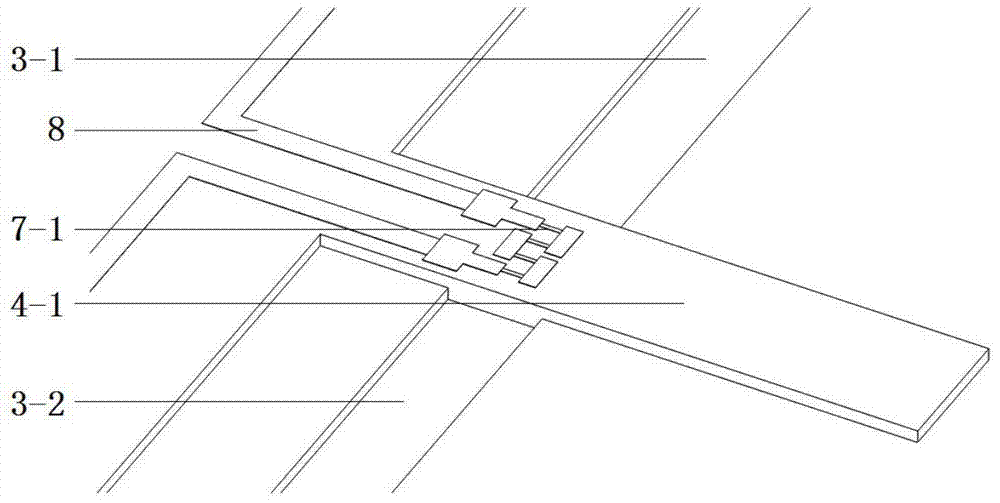

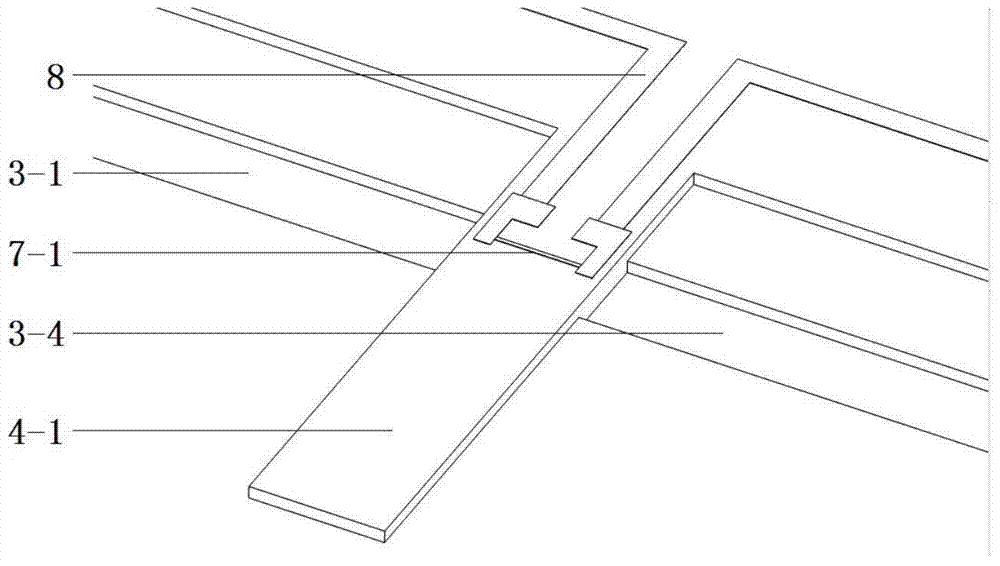

[0041] A beam-groove combined with a step-type island membrane micro-pressure sensor chip, including a thin film 2 arranged in the middle of a substrate 1, referring to Fig. 1(a), Fig. 1(b), Fig. 1(c), figure 2 , the four shallow grooves 3-1, 3-2, 3-3, 3-4 are evenly distributed along the upper edge of the film 2, and the depths of the four shallow grooves 3-1, 3-2, 3-3, 3-4 are 2 5% to 90% of the thickness; four embossed beams 4-1, 4-2, 4-3, 4-4 are arranged between the ends of two adjacent shallow grooves and connected to the base 1, and the four embossed beams 4 The height of the upper surface of -1, 4-2, 4-3, 4-4 above the upper surface of the film 2 is 5% to 90% of the thickness of the film 2, and the embossed beams 4-1, 4-2, 4-3, 4 The upper surface of -4, the upper surface of the film 2 and the bottom surfaces of the shallow grooves 3-1, 3-2, 3-3, and 3-4 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com