Thin-film permeameter and measuring method thereof

A technology of permeation meter and membrane, which is applied in the field of chemical engineering, can solve the problems of complex measurement process, low precision of measurement results, failure to eliminate the influence of membrane leakage and degassing and environmental temperature fluctuations, etc., and achieve simple measurement process and accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

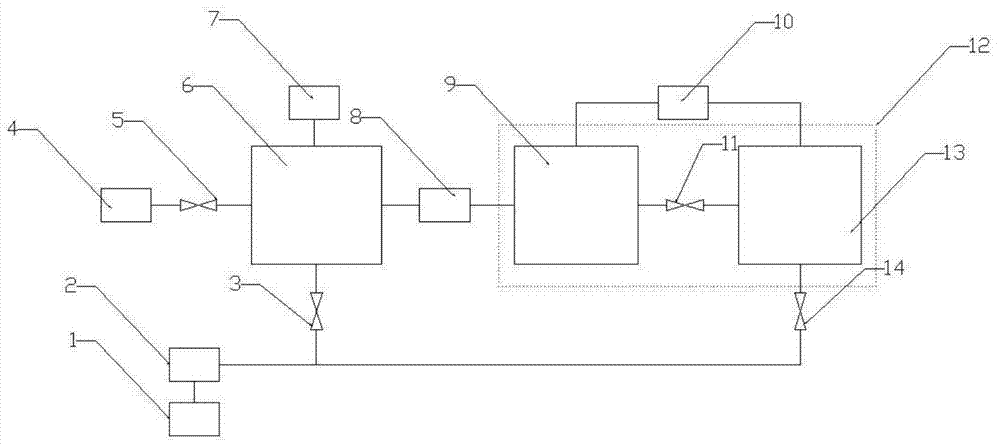

[0025] Specific Embodiment 1: This embodiment is a membrane permeation instrument including a mechanical pump 1, a molecular pump 2, a first valve 3, a gas source 4, a second valve 5, a high pressure chamber 6, a vacuum gauge 7, a gas permeation unit 8, Measuring chamber 9, differential pressure transmitter 10, third valve 11, heating belt 12, reference chamber 13, fourth valve 14;

[0026] The mechanical pump 1 and the molecular pump 2 are vacuum pumping units; the molecular pump 2 communicates with the high-pressure chamber 6 through the first valve 3; the molecular pump 2 communicates with the reference chamber 13 through the fourth valve 14; the gas source 4 communicates with the second valve 5 communicates with the high-pressure chamber 6; the measuring chamber 9 communicates with the reference chamber 13 through the third valve 11; the gas permeation unit 8 separates the high-pressure chamber 6 from the measuring chamber 9; the vacuum gauge 7 is connected with the high-pr...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the volume of the high-pressure chamber 6 is 20 times that of the measurement chamber 9 and the reference chamber 13 . Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that the vacuum gauge 7 measures the pressure of the high-pressure chamber 6 to ensure that the pressure in the high-pressure chamber 6 is 101325 Pa. Other steps are the same as those in Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com