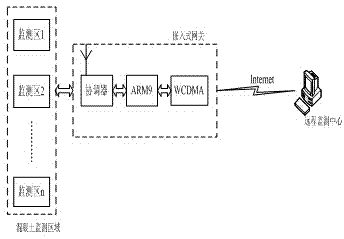

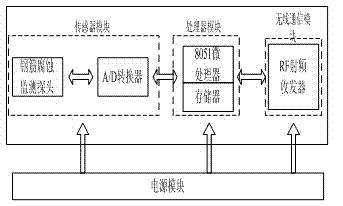

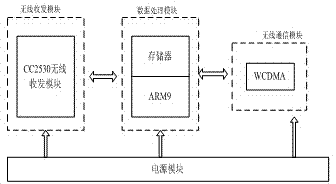

WSN-based remote wireless monitoring system for concrete reinforcement corrosion degree

A technology for concrete reinforcement and monitoring systems, applied in signal transmission systems, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems of dynamic and continuous monitoring of steel corrosion, signal interference, heavy workload, etc., to achieve Excellent signal processing and control capabilities, real-time transmission, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 7 As shown, in the production of concrete specimens, the ratio of cement, sand, and water is 1:1:0.5 to pour concrete specimens. The cement used in the experiment is Conch Cement P.C32.5, and the size of the specimens is 150mm*100mm*60mm , with a built-in common steel bar and a manganese dioxide solid reference electrode. The structure of the test piece is shown in the figure. A saturated calcium hydroxide solution was prepared to simulate the pore solution in the concrete structure. Since steel bars are in a passive state in strongly alkaline concrete and are not easily corroded, a certain concentration of NaCl solution is added to saturated calcium hydroxide solution, and then the prepared concrete specimens are placed in the composite solution for 30 days of maintenance. , to accelerate its corrosion;

[0040] Such as Figure 8 As shown, the wireless monitoring technology for the corrosion degree of steel bars in concrete structures is still immat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com