Method for arranging crossed cylindrical roller slewing bearing stiffness matrix through mechanics modeling

A cross-cylindrical roller, slewing bearing technology, used in roller bearings, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below in combination with specific embodiments.

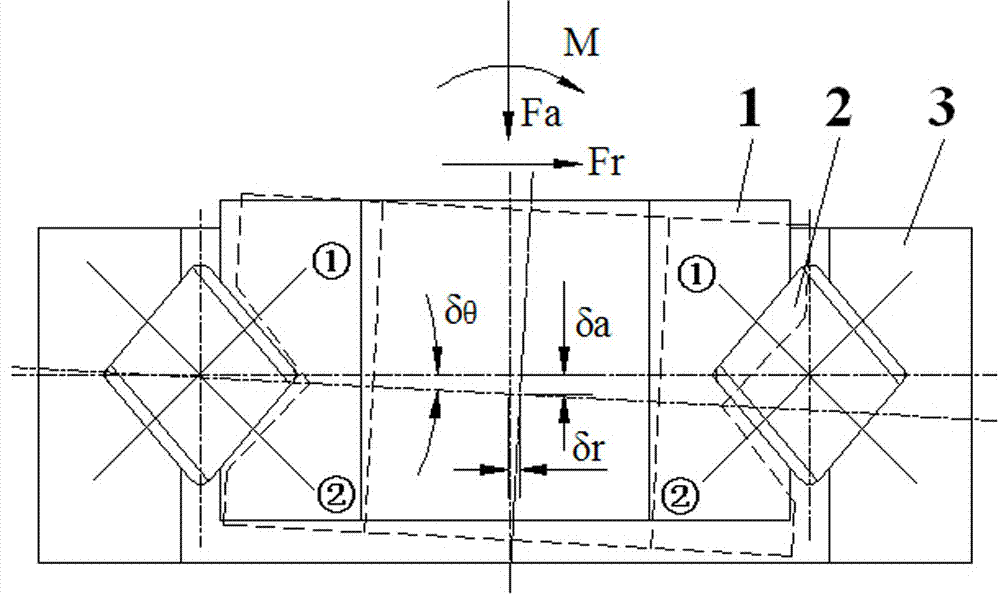

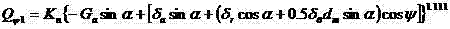

[0046] A method for setting the stiffness matrix of a crossed cylindrical roller slewing bearing through mechanical modeling. The crossed cylindrical roller slewing bearing is mainly composed of an inner ring, an outer ring and cylindrical rollers. Under the action of an external load, the slewing bearing Relative displacement of the inner ring relative to the fixed outer ring, assuming an external radial load , axial load and overturning moment load Under the combined action of , the corresponding radial displacement, axial displacement and inclination displacement of the inner ring are respectively: , and , in the axial plane of the bearing, the raceway of the crossed roller slewing bearing is composed of four line segments, one raceway between the loaded roller and the inner raceway and the other raceway on the outer raceway in the opposite direction The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com