Filtering device used for gas-solid separation

A technology of gas-solid separation and filtration device, which is applied in the direction of dispersed particle filtration, separation method, and dispersed particle separation, etc. It can solve the problems that the advantages of use cannot be well taken into account, and the sealing performance is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

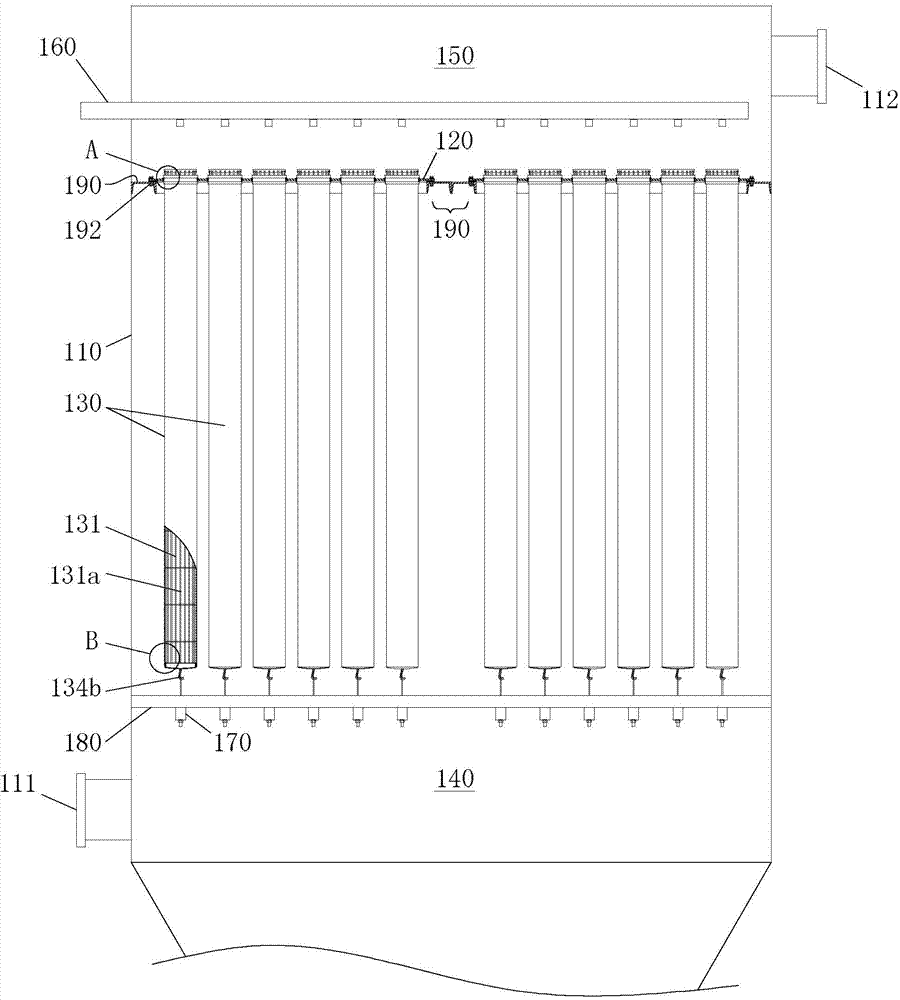

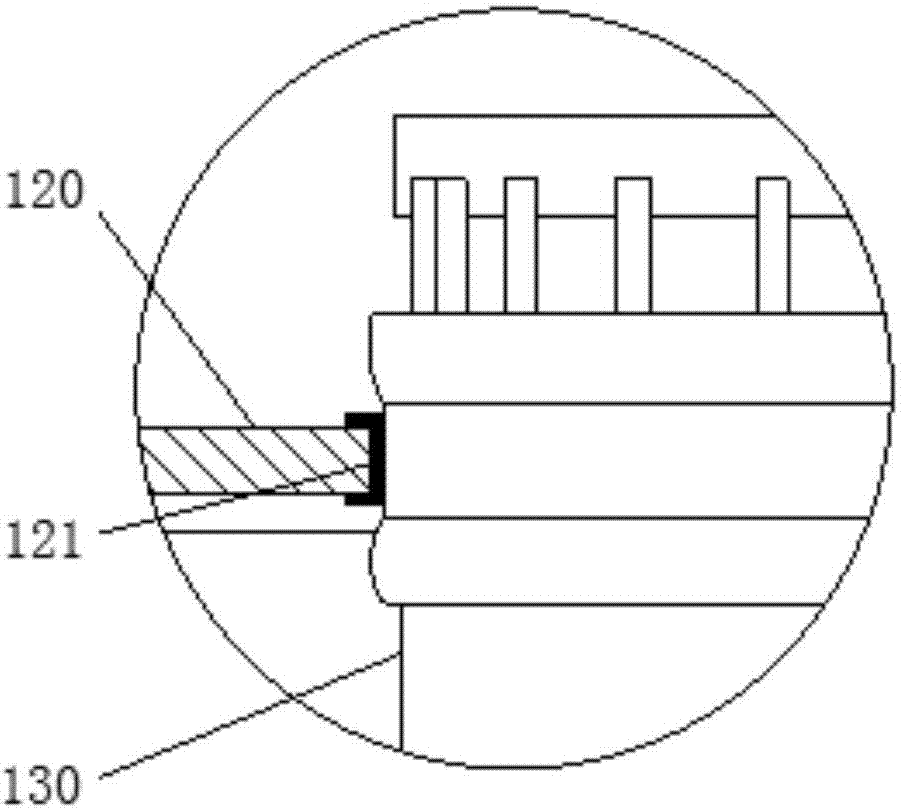

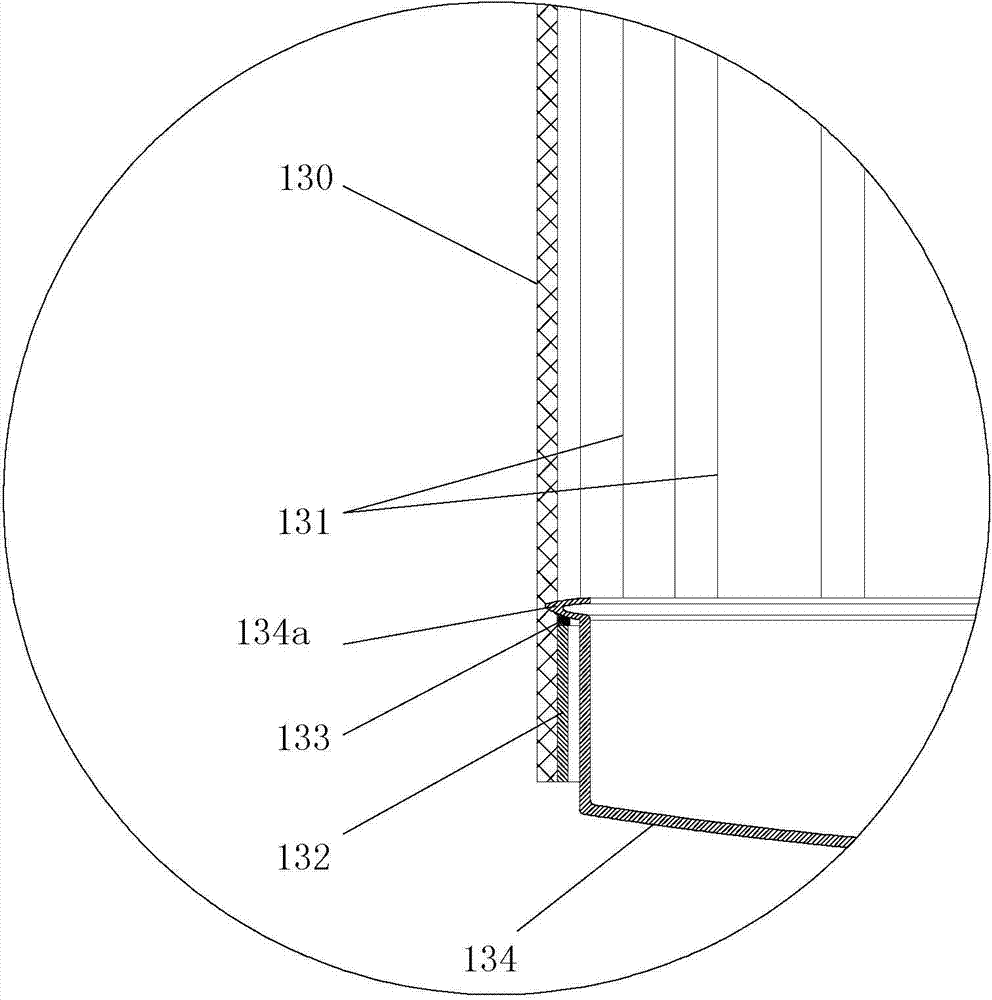

[0025] Such as Figure 1~3 , The bag body of the filter bag 130 is composed of the expanded polytetrafluoroethylene membrane and the inner tank made of glass fiber fabric. The thickness of the liner is 0.5 mm, its longitudinal tensile strength is 580KN / m, and its transverse tensile strength is 430KN / m. The filter bag 130 has a length of 12 meters and a diameter of 300 millimeters. A sealing ring 121 is provided between the upper end sidewall of each filter bag 130 and the filter bag installation hole of the orifice plate 120, and a rigid sealing end cover 134 is installed at the lower end of each filter bag 130, and the bottom center of each sealing end cover 134 is installed There is a pull hook 134b connected to the corresponding elastic pulling device 170, and the sealing end cap 134 and the cylindrical cage structure 131a are independent components. image 3 shown in the same manner. The elastic pulling device 170 adopts a spring cylinder, one end of the spring cylinder...

Embodiment 2

[0027] On the basis of Embodiment 1, Embodiment 2 further improves the structure of the lower end of each filter bag 130 . Specifically, as image 3 As shown, the top of the sealing end cover 134 is welded together with the bottom of the cylindrical cage structure 131a; in addition, the lower end of each filter bag 130 is also provided with an inner flange, which includes a rigid annular support integrated with the filter bag 130 A sheet 132, a sealing ring 133 is provided between the upper end of the rigid annular sealing sheet 132 and the upper outer flange 134a of the sealing end cover 134. Wherein, the inner flange can be formed by directly fixing the rigid annular support piece 132 on the inner wall of the lower end of the filter bag 130, or can be formed by wrapping the rigid annular support piece 132 into the flange at the lower end of the filter bag 130. the inner flange. The rigid annular support sheet 132 is formed from an annular steel sheet. image 3 Among them,...

Embodiment 3

[0029] On the basis of Embodiment 2, Embodiment 3 further improves the installation method of each filter bag 130 in the box body 110 . Specifically, as figure 1 , 4 As shown, the box body 110 is equipped with an orifice plate supporting positioning structure 190. In this embodiment, the orifice plate supporting and positioning structure 190 is arranged with four filter assembly installation through holes 191 (such as Figure 4 It can be seen that the four filter assembly installation through holes 191 are in a planar rectangular array), each filter assembly installation through hole 191 is correspondingly equipped with a group of filter assemblies, and the filter assembly includes a hole that is detachably sealed with the orifice plate support positioning structure 190 The plate 120 and the filter bags 130 connected to the orifice plate 120 pass through the corresponding filter assembly installation through-holes 191 . Wherein, the orifice plate support and positioning stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com