Iron tower material corrector

A technology of orthotics and tower materials, which is applied in the field of orthotics for iron towers and towers, can solve problems such as equipment safety and operation safety hazards, poor performance, and difficulty in restoring the original shape of iron tower main materials, so as to improve the scope of operability and improve Job completion rate and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

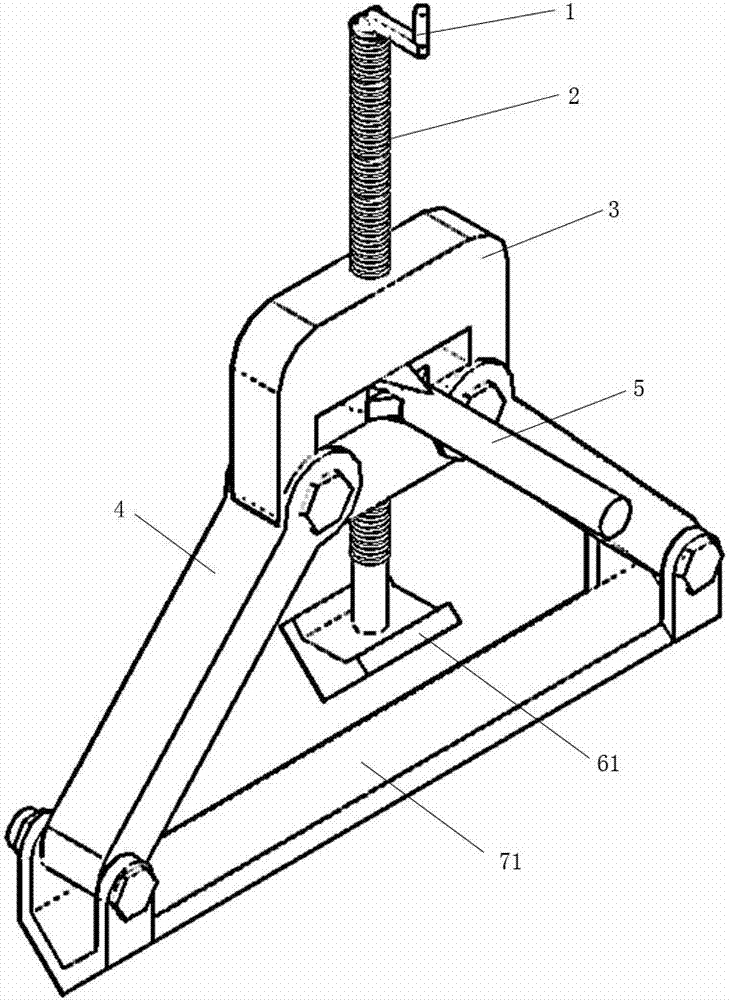

[0013] like figure 1 As shown, the iron tower tower material corrector includes: lead screw crank handle 1, elastic screw 2, main load-bearing platform 3, load-bearing bracket 4, correction terminal and support bracket, and the main load-bearing platform as a whole is Square to carry the primary springback force from the orthotic terminals. The middle part of the upper and lower beams of the main load-bearing platform has a through hole, and the bottom end of the elastic screw 2 passes through the through hole from top to bottom and is connected with the correction terminal, and the elastic lead screw is used to transmit the thrust to the correction terminal.

[0014] A lead screw handle 1 is installed on the top of the elastic lead screw 2, and the lead screw is rotated by the lead screw handle to quickly adjust and correct the desired position of the terminal before being stressed.

[0015] There are two load-bearing brackets 4, the top of the load-bearing bracket is connec...

Embodiment 2

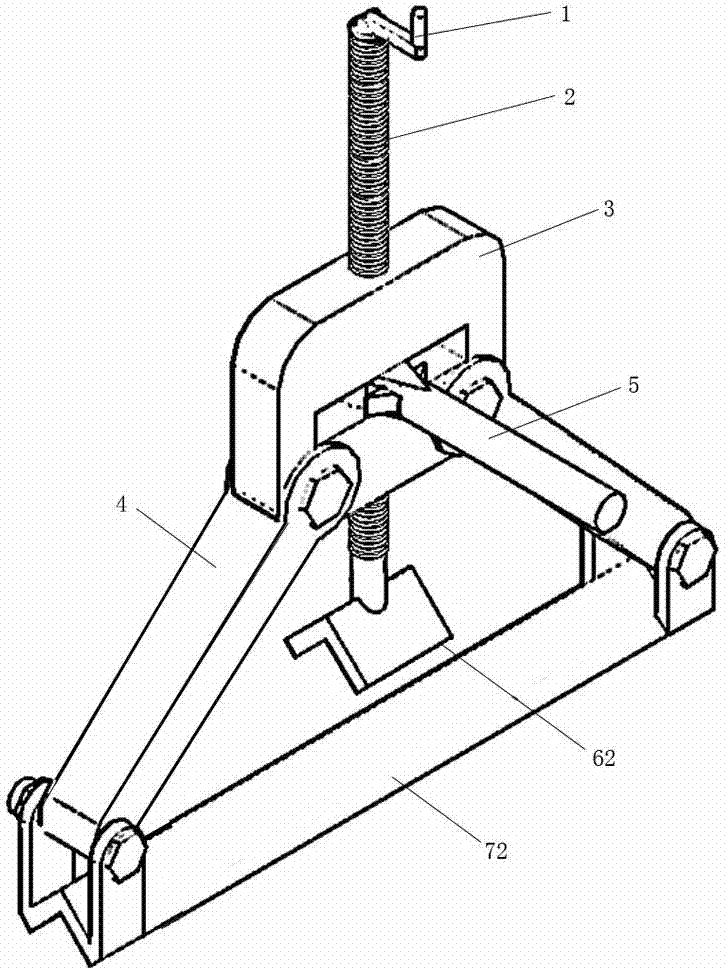

[0018] like figure 2 As shown, the iron tower tower material corrector includes: lead screw crank handle 1, elastic screw 2, main load-bearing platform 3, load-bearing bracket 4, correction terminal and support bracket, and the main load-bearing platform as a whole is Square to carry the primary springback force from the orthotic terminals. The middle part of the upper and lower beams of the main load-bearing platform has a through hole, and the bottom end of the elastic screw 2 passes through the through hole from top to bottom and is connected with the correction terminal, and the elastic lead screw is used to transmit the thrust to the correction terminal.

[0019] A lead screw handle 1 is installed on the top of the elastic lead screw 2, and the lead screw is rotated by the lead screw handle to quickly adjust and correct the desired position of the terminal before being stressed.

[0020] There are two load-bearing brackets 4, the top of the load-bearing bracket is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com