Surfboard

A surfboard and board body technology, applied in the field of surfboards, can solve the problems of not taking into account the firmness of the bottom of the surfboard, the unreasonable method of making the surface structure, and the unsatisfactory surface strength, so as to achieve smooth bottom surface, enhanced strength, and flexible use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

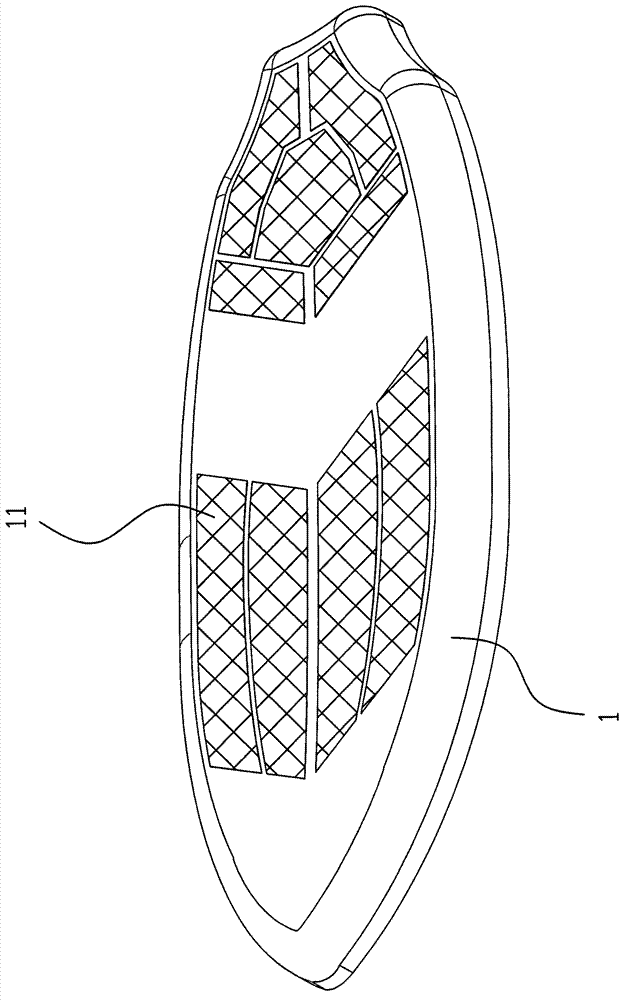

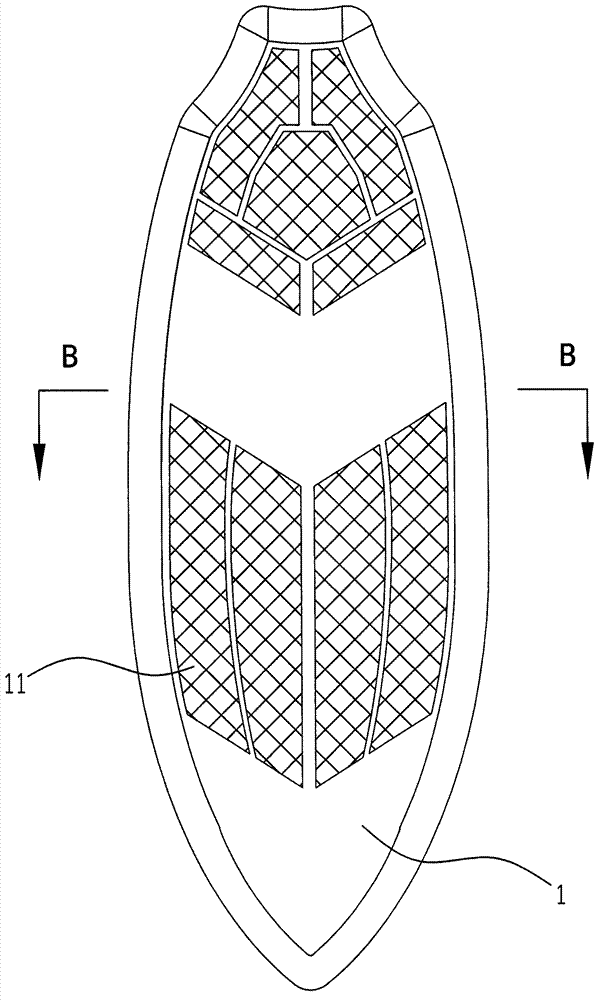

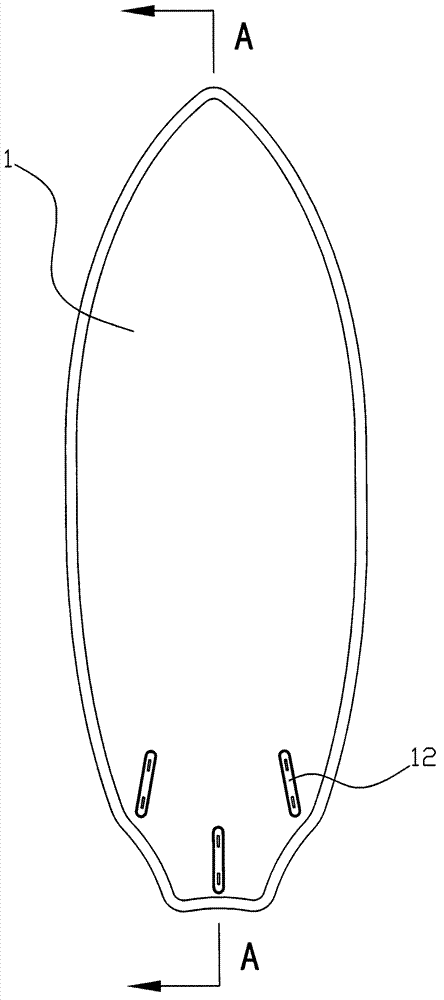

[0027] Such as Figure 1 to Figure 11 As shown, the surfboard of this embodiment includes a board body 1, and the board body 1 is composed of an upper layer 2, a foam core board 3, and a bottom layer 4 made of organic high-resolution materials, and the upper layer 2 and the bottom layer 4 combine foam The core board 3 is wrapped in the middle, and the bottom layer 4 is composed of a bottom surface layer and a foamed plastic inner layer 41, and the bottom surface layer is sequentially composed of a transparent first polyethylene layer 42, a patterned non-woven fabric from bottom to top. Layer 43, the second polyethylene layer 44, the non-woven fabric layer 43 of increasing strength, the third polyethylene layer 45, the first polyethylene layer 42, the second polyethylene layer 44 and the third polyethylene layer 45 are melted respectively When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com