Elevator band-type brake power supply

A technology of power supply and elevator, applied in the direction of hoisting device, etc., can solve the problems of large inrush current and high withstand voltage requirements, and achieve the effect of prolonging the service life and reducing the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

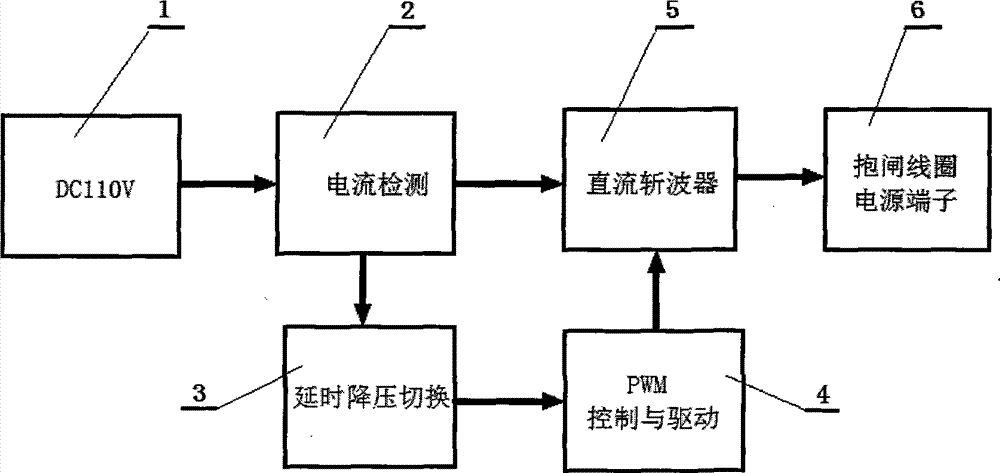

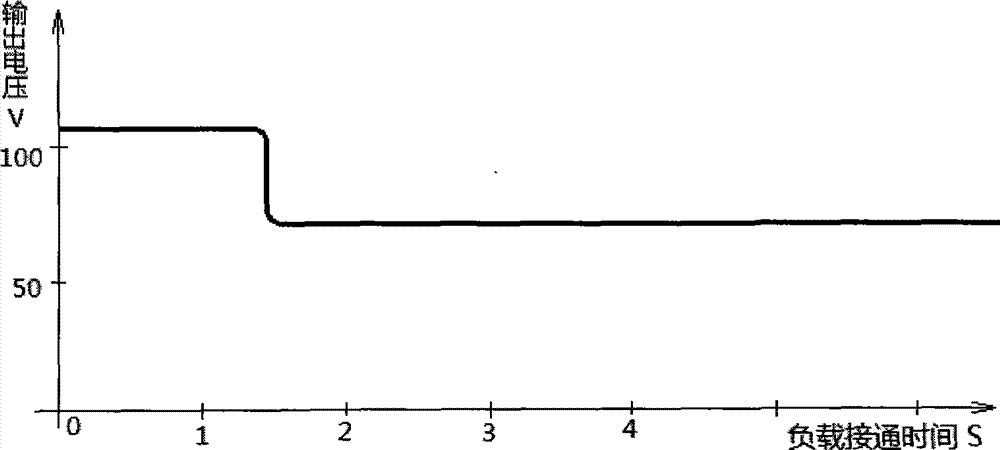

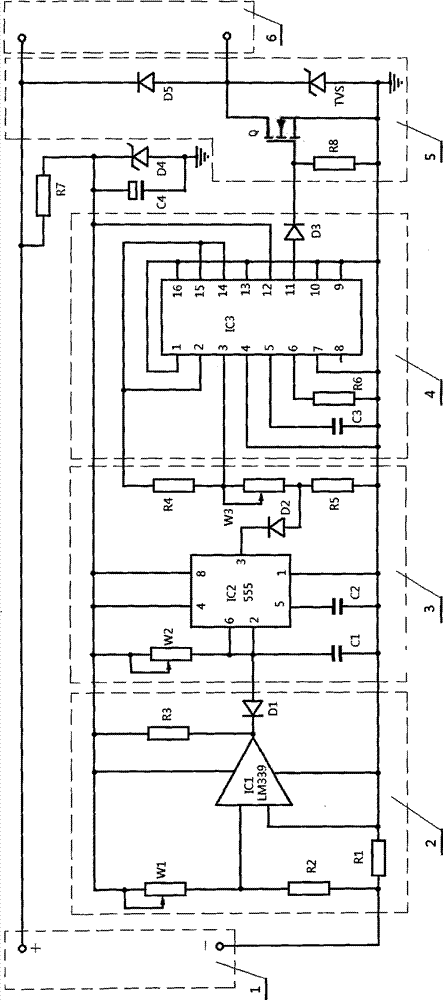

[0017] exist figure 1 Among them, the input of the circuit is the power supply 1, which is DC110V direct current, and the output is the brake coil power terminal 6, which is connected to the brake coil through the moving contact of the brake contactor of the elevator control system. The current detection circuit 2 monitors the change of the output current, and can output a signal that the brake coil power terminal 6 connects the load each time. When there is no load connection signal, the output pulse width of the PWM control and drive circuit 11 is 90%-96% (can be set), and the DC chopper circuit 5 is driven to output a high voltage. When the load is connected, the initial voltage is the high voltage output by the DC chopper circuit 5; the current detection circuit 2 outputs the load connection signal, which triggers the timer of the delay step-down switching circuit 3 to start counting, and after 1.5 seconds (can be set After setting), the pulse width control voltage of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com