A method of wet firing sea sand into high-strength building materials

A technology for building materials and sea sand, which is applied in the field of preparing building materials by utilizing natural resources, can solve problems such as corrosion of steel bars and hidden dangers of engineering safety, and achieve the effect of avoiding corrosion and reducing environmental load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

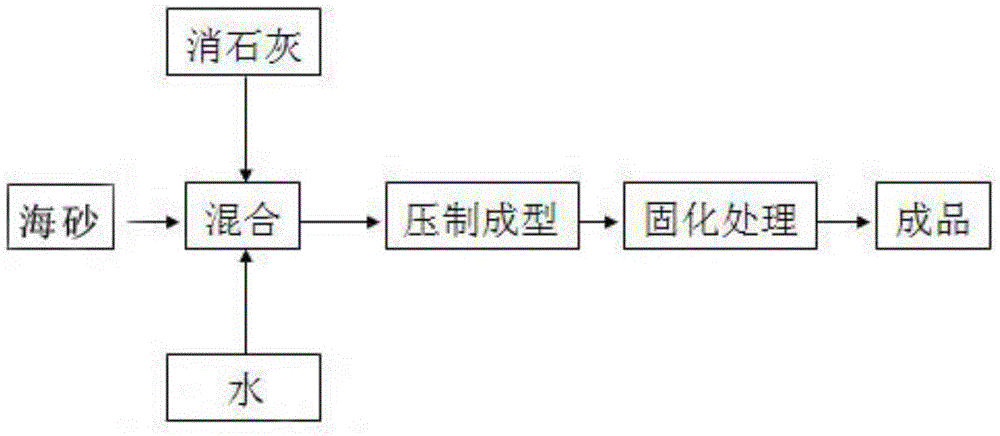

[0028] First, if figure 1 The technological process uses sea sand as the main raw material, and wet-fires the sea sand into building material samples.

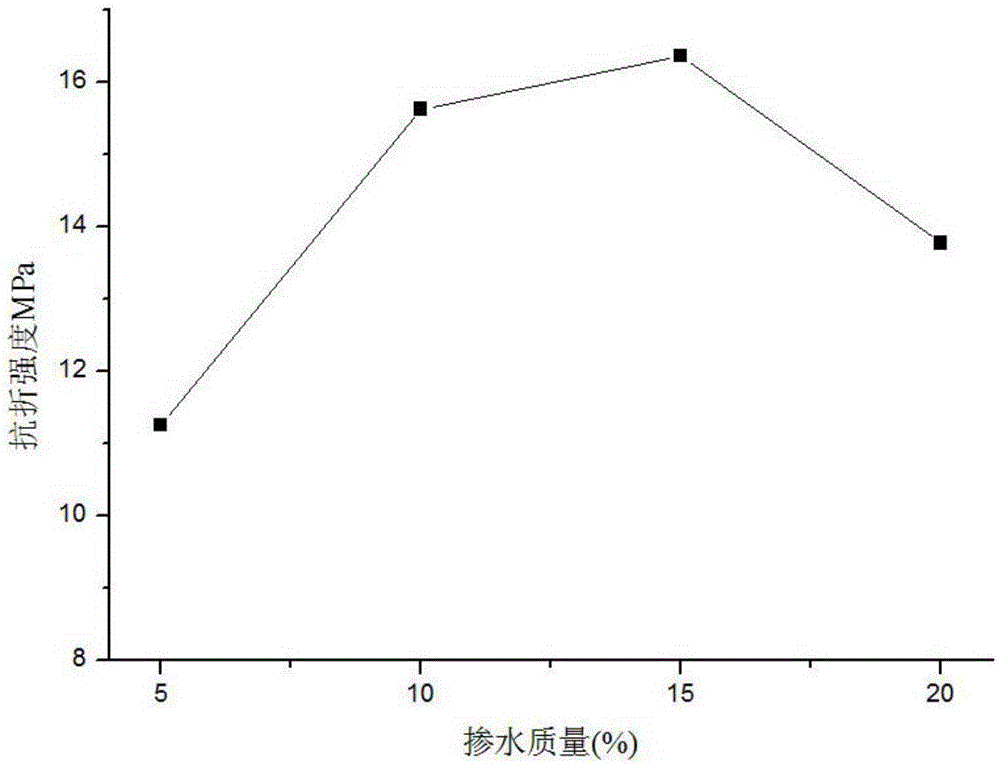

[0029] First grind the sea sand, pass through a 100-mesh sieve, and measure the ground sea sand: commercially available analytically pure slaked lime powder = 75%: 25% by mass, stir evenly to obtain a mixture, and then add seawater, the amount of seawater added It is 15% mass percent of the total weight of sea sand and slaked lime powder. After fully stirring evenly, press it into a micro-brick green body under a tablet press (model FY-15), and put the pressed micro-brick green body as a building material sample. Put it into a hydrothermal reactor, and cure it under the saturated vapor pressure of water at 200°C for 10 hours, and finally, obtain a high-strength building material sample.

[0030] The pressed micro-brick green body and the high-strength building material sample (micro-brick) obtained by wet firing were analyzed...

Embodiment 2

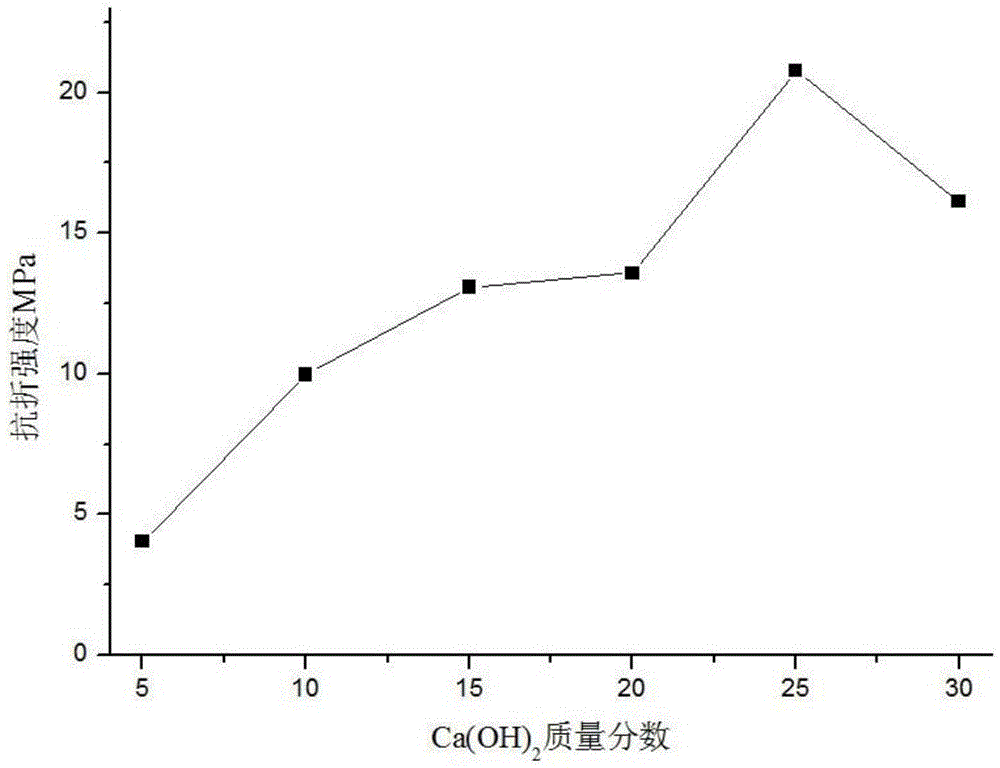

[0040] First of all, choose the sand and gravel directly mined by the sea that have been eroded by seawater without desalination as raw materials, measure sea sand: slaked lime powder = 70%: 30% by mass, stir evenly and add seawater, the amount of seawater added is 10% by mass of the total weight of sea sand and slaked lime, after fully stirring evenly, press and form in the mold of ordinary pavement bricks to obtain the green body of ordinary pavement bricks; finally, put the pressed green body of ordinary pavement bricks into the hydrothermal reactor Curing treatment at 160°C under the saturated vapor pressure of water for 10 hours to obtain ordinary pavement bricks. After testing, its flexural strength can reach 20MPa.

Embodiment 3

[0042] First, choose sea sand as raw material, measure sea sand: slaked lime powder = 80%: 20% by mass, then add sea sand and sea water with 15% of the total weight of slaked lime, stir well and put it into a cement reef mold to press it into Cement reef green body; finally, put the pressed green body into a hydrothermal reactor, and solidify under the saturated vapor pressure of water at 240°C for 10 hours to obtain an artificial fish reef (cement reef). After testing, its flexural strength can reach 20MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com