Cloth shoe with high comfort level and manufacturing process thereof

A technology of manufacturing technology and comfort, which is applied in the field of cloth shoes and its manufacturing technology, can solve the problems of insufficient extraction rate of active ingredients, improvement of the utilization rate of bark, and difficulty in recycling, etc., to assist and promote the destruction of cell wall structure, improve Bioavailability, short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

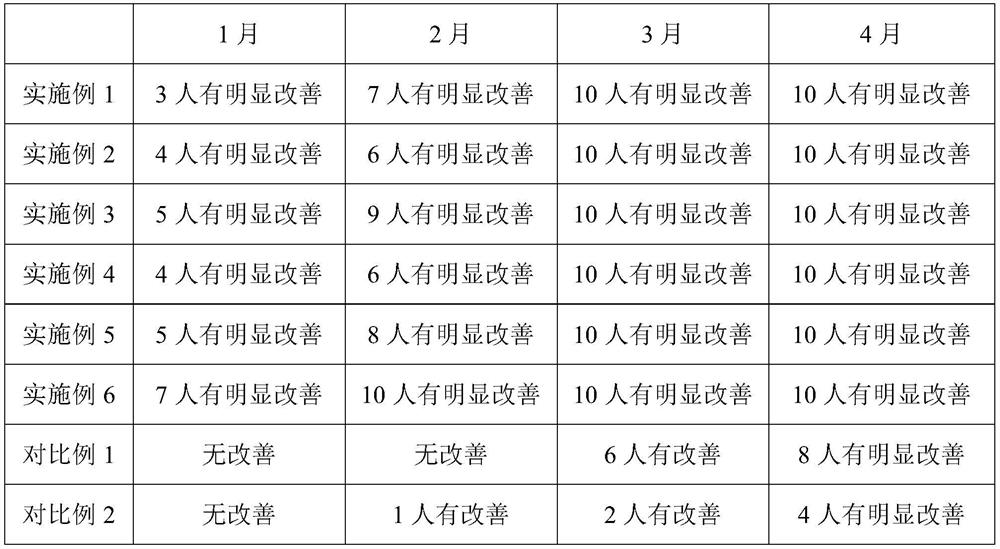

Embodiment 1

[0033] A manufacturing process for cloth shoes with high comfort, comprising the following steps:

[0034] S1, leaching: get the dry bark (moisture is 5wt%), cross 50 mesh sieves after pulverizing, add acidic ionic liquid aqueous solution ([BsEt 3 N][HSO 4 ] 0.5 parts of acidic ionic liquid, 100 parts of water), leaching treatment for a period of time, leaching temperature 45 ℃, leaching time 15h, filtering to obtain filtrate;

[0035] S2, concentrating: add binder 0.1wt% ethylene-vinyl acetate copolymer emulsion in the obtained filtrate, plasticizer 0.1wt% citric acid ester, thickener 0.1wt% methylcellulose and chelating agent 0.02wt% EDTA, Heat and stir at 40°C and concentrate until the water content is 30wt%, to obtain a concentrate;

[0036] S3. Manufacturing of shoe sole: Cover the base of the shoe sole with a layer of concentrated solution with a thickness of 1 mm, place it in a naturally ventilated place to dry and solidify, and then set a cotton filling layer on the ...

Embodiment 2

[0039] A manufacturing process for cloth shoes with high comfort, comprising the following steps:

[0040] S1, leaching: get the dry bark (moisture is 30wt%), cross 10 mesh sieves after pulverizing, add acidic ionic liquid aqueous solution ([BsEt 3 N][AlC1 4 ] 2 parts of acidic ionic liquid, 100 parts of water), leaching treatment for a period of time, leaching temperature 25 ℃, leaching time 24h, filtering to obtain filtrate;

[0041] S2, concentration: add binder 0.5wt% amino resin, 0.5wt% vulcanized silicone rubber in the obtained filtrate, plasticizer 1wt% polyethylene glycol-200, thickener 0.5wt% carboxymethyl cellulose, 0.5 wt% polyquaternium 1 and chelating agent 0.2wt% disodium EDTA, heated and stirred at 70°C and concentrated until the water content was 10wt%, to obtain a concentrated solution;

[0042] S3, manufacture of sole: Cover the base of the sole with a layer of concentrated solution with a thickness of 10 mm, place it in a naturally ventilated place to dry ...

Embodiment 3

[0045] A manufacturing process for cloth shoes with high comfort, comprising the following steps:

[0046] S1, leaching: get the dry bark (moisture is 15wt%), cross 20 mesh sieves after pulverizing, add acidic ionic liquid aqueous solution ([BsEt 3 N][H 2 PO 4 ] 5 parts of acidic ionic liquid, 100 parts of water), leaching for a period of time, the leaching temperature is 55°C, the leaching time is 8h, and the filtrate is obtained by filtration;

[0047] S2, concentrating: add binder 0.25wt% vulcanized silicone rubber, 0.25wt% cyanoacrylate in the obtained filtrate, plasticizer 0.5wt% phthalate, thickener 0.25wt% guar gum, 0.25wt% chitosan and chelating agent 0.1wt% EDTA, heated and stirred at 50°C and concentrated until the water content is 20wt%, to obtain a concentrated solution;

[0048] S3, manufacture of sole: cover the concentrated solution with a thickness of 5mm on the sole base, place it in a naturally ventilated place to dry and solidify, then set the cotton fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com